- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5/11kw

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

1500x800x1200mm

-

Name:

-

50 ton per day flour mill/20t wheat flour mill roller mill

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

purpose:

-

to make corn grits and flour

-

output product:

-

2 types gris, 1 type flour

-

grits output percentage:

-

45%

-

flour output percentage:

-

20-30%

-

keyword:

-

small type corn grits machine

-

items:

-

small-size corn milling machine, corn flour mill machine

-

Raw material:

-

Wheat Maize Corn Rice

-

Key words:

-

Used Flour Mills

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Chengli

-

Voltage:

-

380V-50Hz-3Phase

-

Power:

-

7.5/11kw

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

1500x800x1200mm

-

Name:

-

50 ton per day flour mill/20t wheat flour mill roller mill

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

purpose:

-

to make corn grits and flour

-

output product:

-

2 types gris, 1 type flour

-

grits output percentage:

-

45%

-

flour output percentage:

-

20-30%

-

keyword:

-

small type corn grits machine

-

items:

-

small-size corn milling machine, corn flour mill machine

-

Raw material:

-

Wheat Maize Corn Rice

-

Key words:

-

Used Flour Mills

Product Overview

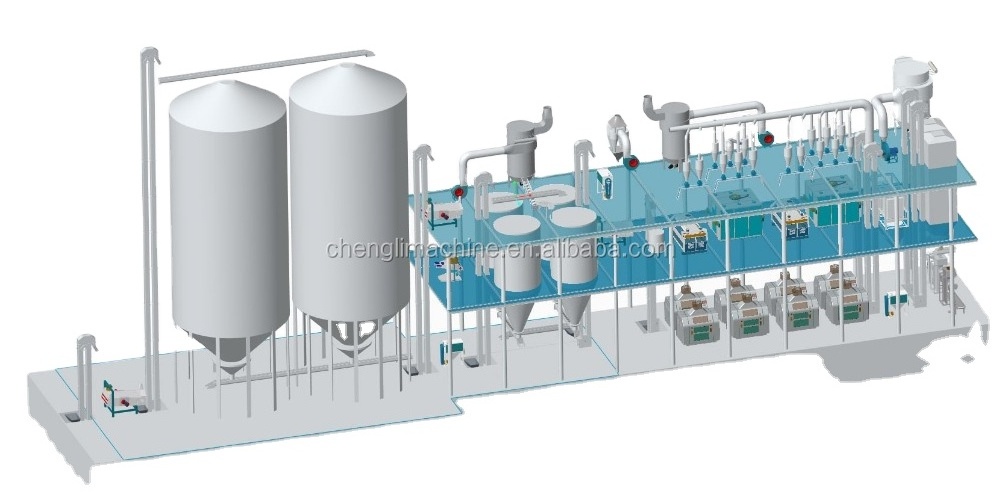

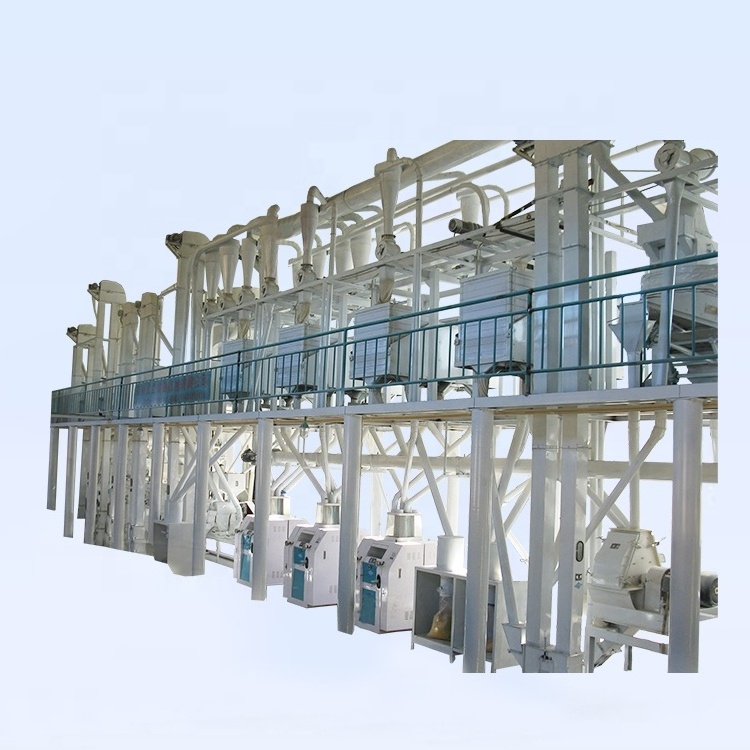

wheat flour mill price/wheat roller miller/wheat milling machine with different capacity 5t-500t per day.

FEATURES AT A GLANCE

Technique flow of wheat roller mill machine

Crafting process:

The main process of wheat milling is to separate the endosperm from the wheat germ and wheat husk after the wheat grain is cleaned

and water-regulated, and then the endosperm is ground into powder; later, according to the consumption needs, different grades of

flour are prepared. Sometimes it is necessary to make various special powders through flour treatment.

Input wheat –>wheat cleaner–> wheat moisture dampener–>roller mill–>plansifter–>good quality flour –>packing

The main process of wheat milling is to separate the endosperm from the wheat germ and wheat husk after the wheat grain is cleaned

and water-regulated, and then the endosperm is ground into powder; later, according to the consumption needs, different grades of

flour are prepared. Sometimes it is necessary to make various special powders through flour treatment.

Input wheat –>wheat cleaner–> wheat moisture dampener–>roller mill–>plansifter–>good quality flour –>packing

100tpd wheat mill production line

10tpd wheat flour mill line

50-60tpd wheat mill

PRODUCT CONFIGURATION

Pneumatic roller mill

High square plansifter

Auto packing machine

Finished Products

Company information

With a manufacturing factory which covers more than 2000 square meters, CHENGLI aims to offer the first-rate design work, high quality machinery and perfect technology serving system to customers.

We employee approximately 20 technicians to design, manufacture, install and commissioning turnkey projects for both the domestic and overseas market. We carry out a strict quality management system in accordance with ISO9001 requirements and provide a coordinated-process service including the plant layout, the process flow and the instillation technical guidance. Our customers all over the world, such as Mozambique, Egypt, Nigeria, Kenya, Ethiopia, Uganda, Thailand, Vietnam, Philippines, Mexico, Australia, Tanzania and Saudi Arabia, Sweden, Bangladesh, Korea, Sri Lanka, Russia, Germany and so on.

How to contact

Cathy:0086 15617867129 (Wechat/WhatsApp/Tel)

Related machines

Hot Searches