- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Li-ion Battery Raw Materials

-

Width:

-

customized

-

Grade:

-

Pure Copper

-

Model Number:

-

T-E-CU

-

Brand Name:

-

TOB

-

Place of Origin:

-

Fujian, China

-

Product name:

-

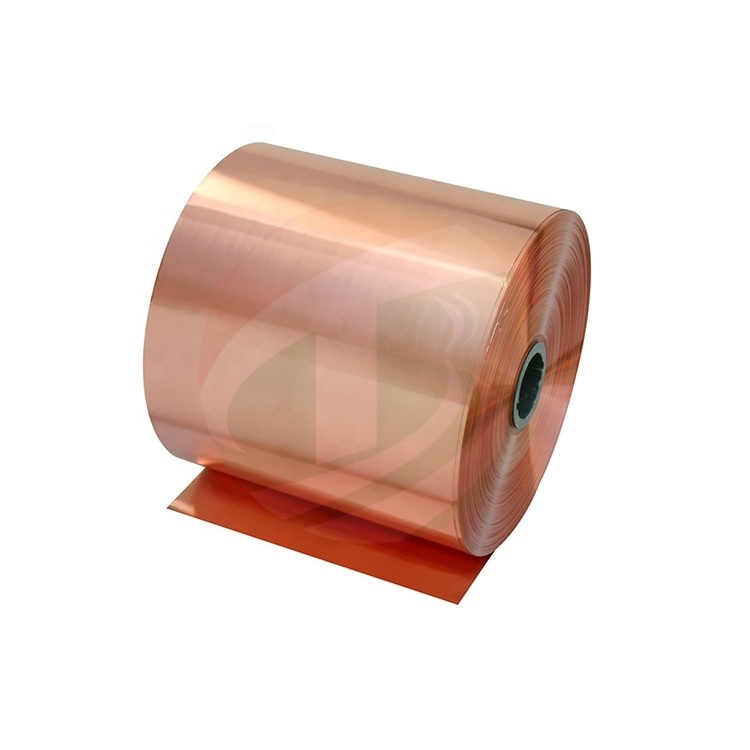

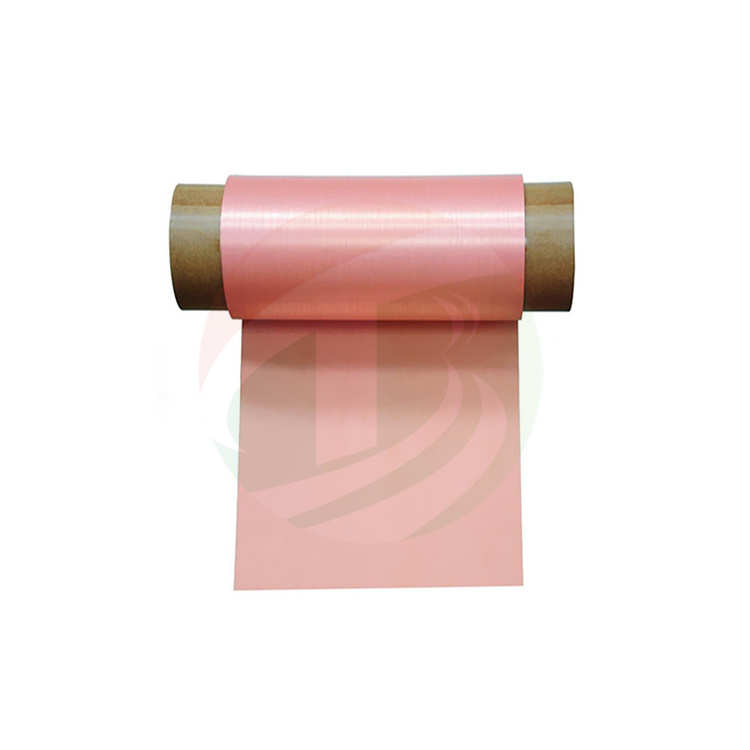

Porous copper foil

-

Related industry:

-

Lithium ion battery

-

Purity:

-

≥99.95%

-

Areal density:

-

130--180g/㎡

-

thickness deviation:

-

±3.0um

-

Tensile strength:

-

≥15.0kg/㎡

-

Room temperature elongation:

-

≥2.0%

-

Shape:

-

Copper Foil Roll

-

Size:

-

2kg/roll

Quick Details

-

Material:

-

Porous copper foil

-

Cu (Min):

-

99.95%

-

Alloy Or Not:

-

Is Alloy

-

Application:

-

Li-ion Battery Raw Materials

-

Width:

-

customized

-

Grade:

-

Pure Copper

-

Model Number:

-

T-E-CU

-

Brand Name:

-

TOB

-

Place of Origin:

-

Fujian, China

-

Product name:

-

Porous copper foil

-

Related industry:

-

Lithium ion battery

-

Purity:

-

≥99.95%

-

Areal density:

-

130--180g/㎡

-

thickness deviation:

-

±3.0um

-

Tensile strength:

-

≥15.0kg/㎡

-

Room temperature elongation:

-

≥2.0%

-

Shape:

-

Copper Foil Roll

-

Size:

-

2kg/roll

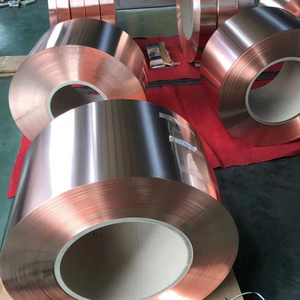

High Conductivity Porous Copper Foil For Lithium ion Battery

SPECIFICATION

1.Technical characteristics

1.1Full interconnection, open, spherical pores, three-dimensional mesh structure

It has good coating property and is easy to be cut

1.2Ultra high conductivity, current collection and maintenance

1.3Can increase the cathode active material significantly

1.4Has good invasion with the electrolyte

1.5Enhance product cooling efficiency

2.Application scope

For lithium ion battery, capacitor current collector or other frequent rechargeable battery

3.Use requirements

Should not be stored in high temperature and humidity conditions for a long time

Main technical specifications of three-dimensional porous copper foil

|

Physical property |

Unit |

Typical parameter |

|

Purity |

% |

≥99.95 |

|

Porosity |

um |

10~15um |

|

Areal density (as per customer requirements) |

g/ m2 |

130--180 |

|

thickness deviation |

um |

±3.0 |

|

Mass electrical resistivity |

Ω.g/ m2 |

≥0.168 |

|

Tensile strength |

kg/ m2 |

≥15.0 |

|

Room temperature elongation |

% |

≥2.0 |

|

Resistance to oxidation ( 180℃ 15min) |

|

OK |

IMAGE

Using