- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

30kw

-

Dimension(L*W*H):

-

700*1000

-

Warranty:

-

1 year

-

Weight:

-

4T

-

Certification:

-

TUV

-

Colour:

-

Customized

-

Size:

-

700*1000

-

Kinds of coating:

-

Tin, TiAIN, TiCN, TIBN, etc

-

Controlling system:

-

PLC and touch screen

-

Working gas:

-

Ar N2 O2

-

Working principle period:

-

PVD vacuum coating

-

Chamber material:

-

High quality stainless steel

-

Whatsapp/Line:

-

008618769414192

-

Wechat:

-

008618769414192

-

Skype:

-

lkcrystalzhang

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LKBT

-

Model Number:

-

DCLD-700

-

Voltage:

-

380V

-

Power:

-

30kw

-

Dimension(L*W*H):

-

700*1000

-

Warranty:

-

1 year

-

Weight:

-

4T

-

Certification:

-

TUV

-

Colour:

-

Customized

-

Size:

-

700*1000

-

Kinds of coating:

-

Tin, TiAIN, TiCN, TIBN, etc

-

Controlling system:

-

PLC and touch screen

-

Working gas:

-

Ar N2 O2

-

Working principle period:

-

PVD vacuum coating

-

Chamber material:

-

High quality stainless steel

-

Whatsapp/Line:

-

008618769414192

-

Wechat:

-

008618769414192

-

Skype:

-

lkcrystalzhang

L o ngkou Bite Vacuum Technology Co. , Ltd . It was founded in 1930. lying on the Beijing Normal University,

Beijing Institute of T the g machinery Shenyang vacuum Technology Research Institute of technical cooperation.

technology and transformation, improve the original technology ability, have independent research development

are development of advanced technology reliable performance and market adaptabaty"BITE" brand are magneton

machine, magnetron man target multi-arc coating machine, intermediate frequency vacuum coating machine anomat tle vacuum coating machine,

high current metal vapor vacuum arc ion impartaton machine. vacuum heat and other series products. A few years,

my company has assumed the 5 natonal and provincial science and won two award of the Shandong provincial science and

technology progress. effectve 10 patents High technology suon vacuum coating equipment is advanced and the adaptability to the market,

a variety of products have been e States, Spain. Scuth Korea, Inda, Canada and other countries and regions.

Company Link: http://longkoubt.en.alibaba.com/ (show our company and products to you............

ion sputtering coating machine

Improved functionality and flexibility are the main advantages of the relatively new coating process "PVD coating for plastic parts".

PVD coating is a multi-stage process. The parts are first pretreated with a primer coat. Thereafter in the PVD process itself the parts are "sputter coated" in a vacuum chamber while electrically charged.

Finally a protective clearcoat layer is sprayed over the metallic finish. Unlike chrome plating there are no cyanide dip tanks or other chemical baths that have negative environmental impacts.

This process has already found applications in automotive logos, cosmetic packaging and in some areas of sanitary engineering.

PVD's flexibility is enhanced through the ability to control the deposition layer thickness, deposition material, availability of various primer and topcoats, and even the part material itself. The combination allows the customer to better control both the appearance and physical properties of the end product.

|

parameters |

Model No. |

Quantity |

|

|

The structure of the vacuum chamber |

Vertical front door , Double or cooling tank cooling |

|

|

|

dimension of vacuum chamber |

700×1000 |

|

1 |

|

pumping speed |

1× 10 5 Pa~3× 10 -3 Pa≤15min |

|

|

|

limit vacuum |

≤ 8 × 10 -4 Pa |

|

|

|

system form a complete set |

Maintaining the pump |

2X-15 |

1 |

|

Mechanical pump |

2X-70 |

1 |

|

|

Diffusion pump |

KT-400 |

1 |

|

|

workpiece system |

Rotation of the planet forms(8 roating shaft, since the amount) |

|

8 |

|

heating methods |

Edge installation of stainless steel heating tube |

|

4 |

|

ion bombardment |

20KW inverter bias |

PLS-20KW |

1 |

|

Arc target |

40-200A adjustable |

TIG-250 |

3 |

|

magnetron target amount |

one plane target or Cylindrical target |

|

2 |

|

Magnetron power |

20KW IF power |

MF-20KW |

1 |

|

working methods |

PLC semi-auto control or PC+PLC auto control |

|

|

|

working gas |

Ar N 2 O 2 |

|

|

|

total power |

30KW |

|

|

|

compress air |

0.4~0.8MPa |

|

|

|

water-cooling system |

hydraulic pressure/water temperature:≤25°C/≥0.25MPa(user provide for himself) |

|

|

Our products have acquired the TUV certification

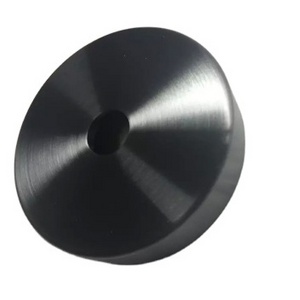

Machine show and Final products show:

|

|