- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TONGHUA

-

Voltage:

-

220/380v

-

Power:

-

10.5kw

-

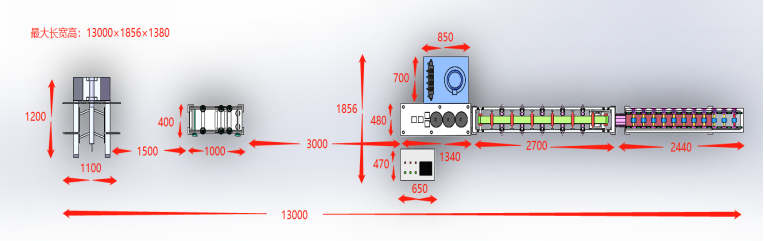

Dimension(L*W*H):

-

15600 x 2360 x 1750mm

-

Weight:

-

4600 kg

-

Product name:

-

Solar Bracket Making Machine PV Support Production Line

-

Color:

-

Cutomized

-

Shaft material:

-

45# Steel

-

Forming Speed:

-

10M/min

-

Roller Station:

-

12 Stations

Quick Details

-

Marketing Type:

-

New Product 2023

-

Work Pressure:

-

450Mpa

-

Production Capacity:

-

10-12M/Min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TONGHUA

-

Voltage:

-

220/380v

-

Power:

-

10.5kw

-

Dimension(L*W*H):

-

15600 x 2360 x 1750mm

-

Weight:

-

4600 kg

-

Product name:

-

Solar Bracket Making Machine PV Support Production Line

-

Color:

-

Cutomized

-

Shaft material:

-

45# Steel

-

Forming Speed:

-

10M/min

-

Roller Station:

-

12 Stations

Product Description

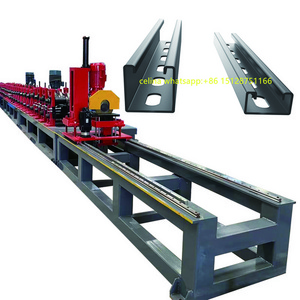

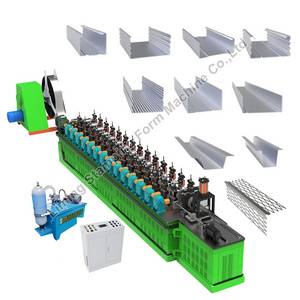

The components of the 2022 Popular Sale C U roll Forming Machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: Suspended C U two profile making machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Equipment features: Suspended C U two profile making machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Process flow of production line:

Uncoiling and discharging → guide straightening → servo feeding → hydraulic punching → hydraulic cutting → feeding platform feeding → cold bending forming → qualified products.

Product Paramenters

1. Rollingmaterial and thickness:

3. Description of main components of the production line:

a. Feeding rack: maximum load 2T, manual type.

b. Straightening machine: upper 5-gear roller, lower 6-gear roller, motor power 1.5KW.

c. Servo feeder: servo motor power 1KW; Brand: Taian.

d. Hydraulic punching and cutting system: the motor power is 4KW, the maximum pressure is 25MPa, and the actual maximum working pressure is 10MPa.

e. Mold material: Cr12MoV, heat treatment hardness: HRC58 ~ 60. 8 molds in total

f. Platform feeder: conveyor belt and upper roller are used for feeding, and the motor is 0.35KW. The main function is to feed the material into the molding machine.

4. Forming host:

(1) Linear speed of forming: 10m/min.

(2) Forming pass: 15 passes (upper and lower 15)

(3) Frame wall-panel structure: the wall-panel is 18mm thick A3 plate, which is fixed on the I-beam with screws, and the I- beam is welded to the frame.

(4) Shaft diameter: Ф 38mm, made of 45 # steel

(5) Roll material: gcr15 finish machining, heat treatment.

(6) Transmission: cycloid pinwheel reduction motor 2.2kw, gear transmission mode

(7) One electric control cabinet, with PLC human-machine touch screen interface and motor protection function. Plc brand isDongyuan, and touch screen brand is Villon.

&= 1.0-1.5mm material; Q235

&= 1.0-1.3mm material; SUS201、SUS304

&= 1.0-1.3mm material; SUS201、SUS304

2. Main components of the production line:

a. Feeding rack 1 set

b. Straightener 1 set

c. Servo feeder 1 set

d. Hydraulic punching and cutting system 1 set

e. Hydraulic pump station 1 set

f. Electric control cabinet 1 set

g. Feeding platform machine 1 set

h. Molding machine 1 set

a. Feeding rack 1 set

b. Straightener 1 set

c. Servo feeder 1 set

d. Hydraulic punching and cutting system 1 set

e. Hydraulic pump station 1 set

f. Electric control cabinet 1 set

g. Feeding platform machine 1 set

h. Molding machine 1 set

3. Description of main components of the production line:

a. Feeding rack: maximum load 2T, manual type.

b. Straightening machine: upper 5-gear roller, lower 6-gear roller, motor power 1.5KW.

c. Servo feeder: servo motor power 1KW; Brand: Taian.

d. Hydraulic punching and cutting system: the motor power is 4KW, the maximum pressure is 25MPa, and the actual maximum working pressure is 10MPa.

e. Mold material: Cr12MoV, heat treatment hardness: HRC58 ~ 60. 8 molds in total

f. Platform feeder: conveyor belt and upper roller are used for feeding, and the motor is 0.35KW. The main function is to feed the material into the molding machine.

4. Forming host:

(1) Linear speed of forming: 10m/min.

(2) Forming pass: 15 passes (upper and lower 15)

(3) Frame wall-panel structure: the wall-panel is 18mm thick A3 plate, which is fixed on the I-beam with screws, and the I- beam is welded to the frame.

(4) Shaft diameter: Ф 38mm, made of 45 # steel

(5) Roll material: gcr15 finish machining, heat treatment.

(6) Transmission: cycloid pinwheel reduction motor 2.2kw, gear transmission mode

(7) One electric control cabinet, with PLC human-machine touch screen interface and motor protection function. Plc brand isDongyuan, and touch screen brand is Villon.

Details Images

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter work Hydraulic oil: 46# Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

Button press and screen touch operate Target piece`s length is adjustable Work automatically The system operate easily

Material of rollers:45# steel, roller surface polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Hydraulic shearing adopts vertical punching shearing, with large shearing force and no burr. It adopts the hydraulic driven and automatic location to decide the dimension and cut the target products. Material of blades: Cr12,quenching treatment. The shear adopts the vertical punching type, the overall frame structure, the slide positioning type.Shear strength is strong, convenient maintenance.

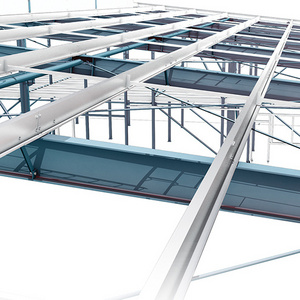

Application

Hot Searches