- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Electric

-

Standard or Nonstandard:

-

Standard

-

Fuel:

-

Gasoline

-

Product name:

-

Sic Ceramic Slurry Pump Parts

-

Usage:

-

SiC Ceramic Heavy Duty Slurry Pump

-

Application:

-

magnetic pump

Quick Details

-

Pressure:

-

High Pressure

-

Place of Origin:

-

Hebei, China

-

Theory:

-

Electromagnetic Pump

-

Power:

-

Electric

-

Standard or Nonstandard:

-

Standard

-

Fuel:

-

Gasoline

-

Product name:

-

Sic Ceramic Slurry Pump Parts

-

Usage:

-

SiC Ceramic Heavy Duty Slurry Pump

-

Application:

-

magnetic pump

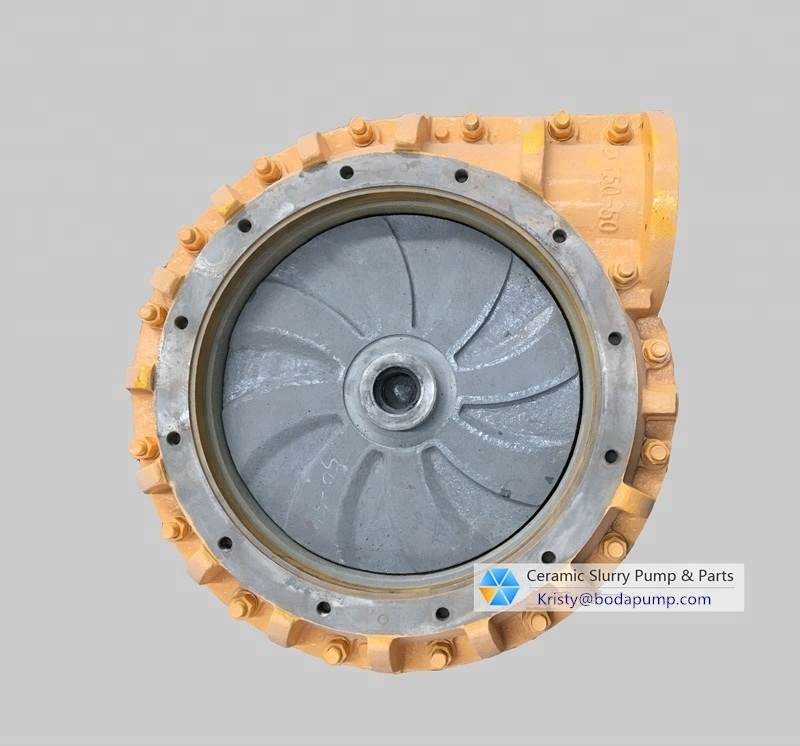

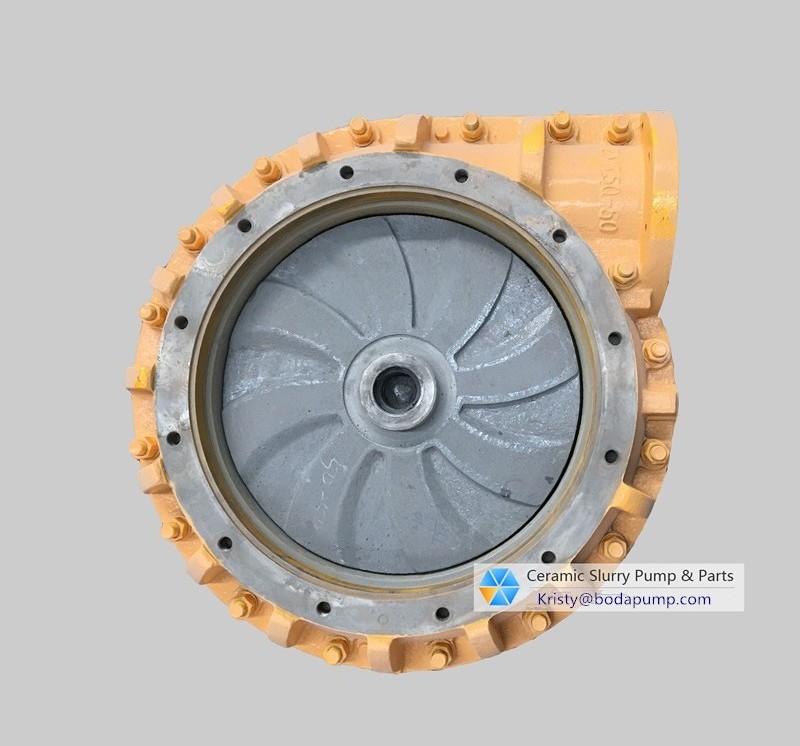

Ceramic Slurry Pump Parts

Product Description

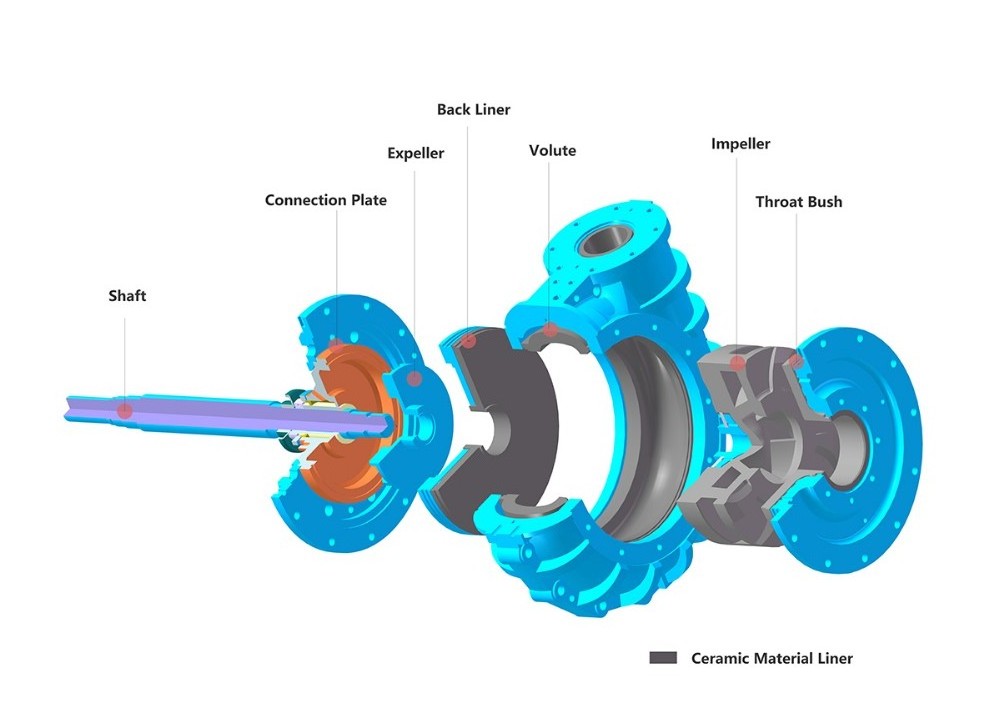

The impeller is the main rotating component which normally has vanes to impart and direct the centrifugal force to the liquid.

Closed Impeller

Impellers are generally closed because of higher efficiencies and are less prone to wear in the front liner region.

Efficiency Francis Vane

Some advantages of the Francis vane profile are the higher efficiency, improved suction performance and slightly better wear life in certain types of slurry because the incidence angle to the fluid is more effective.

Concave Designed

The impeller is concaved designed, the pressure around the shrouds will be lower, so it will have a better wear performance.

Material

The wet parts are made of silicon carbide ceramic by sintering processing, which will give the pump exccellent wear and corrosion resistan performance, and it can also resistant impact by large particles(<15mm) in slurry. These are what metal alloy pump can not do.

- Wear resistant

- corrosion resistant

- Stand impact

Customer Case-Concentrate Feed Pump

Client

Mineral sands operations in South West of Western Australia.

Equipment

3/2C-AH series Warman pump running at ~2000 rpm.

Duty

Concentrated mineral transfer with acid pH 2.0

Original Equipment Trim

Polyurethane or rubber trim. High cost specialty alloy impeller.

Original Equipment Life

2 weeks on polyurethane or rubber trim. 2.5 to 3 weeks on costly specialty alloy impeller.

Ceramic Pump Trim

Ceramic Impeller, Ceramic Volute, Ceramic Frame Plate.

Ceramic wet parts Life

20 weeks on Ceramax components with approx. 10 to 15% wear on leading edge of impeller vanes. Volute and FPLI show no signs of localised or uniformed wear.

Current Outcomes

Existing life improvement of over 2000% against original equipment fit up.

Projected Outcomes

Based on existing wear rates it is anticipated that the Ceramax parts will remain in place for another 20 weeks at which time they will be re-inspected. This would result in a life improvement of over 4000% against the original equipment best results.

The slurry pump parts consists wet parts, sealing parts, bearing assembly, pedestal and other parts.

In slurry pump, Wet Parts means the lining parts which contact with fluid media, usually it include impeller, volute, frame plate, throat bush. There parts will easily get corrosived or abrasived when working and get repalced every periods.

Usually the pump parts are made of iron, steel, bronze, brass, aluminum, plastic etc. For Slurry pumps they are normally made of High chrome alloy, elastomer, polyurethane, ceramic and some other customed. But High chrome alloy and elastomer are now the main material for the slurry pumps. Recent years some companies are trying to make wet parts by ceramics and many data come from labs and mills show that the ceramic wet parts can work for a longer time than high chrome alloy.

For chrome alloy material, the common type is High chrome Alloy(27%Cr), it can be used from Ph 5 to 12, and its hardness can be to HRC58, which is a very good choice for slurry control and transport. But in some conditions, the Ph may lower than 5, then we try A49, it can lower to Ph4, mostly used in FGD processing.

The elastomer are widely used in fine slurry conditions and lower Ph to 2. There are also many rubbers for different conditions, such as R08, R26, R55, S02, etc.

And recently, Polyurethane becomes popular in some conditions. It is good at corrosion and wear conditions.

What's more Ceramic material for slurry pump is perfect to replace elastomers and polyurethane in some condition. High Hardness and great corrosion make it even can replace the metal impeller in some conditions.

The most important things for stopping ceramic slurry pump to replace other ones are the price and friability. But some companies have solved these problems, that is to say some companies have made it success to manufacturing ceramic slurry pump that can stand impact by particles in the fluid media and the pump is not such expensive.

High quality

Passed the ISO9001:2015 quality system authentication and ROHS authentication.

High quality

Passed the ISO914001:2015 quality system authentication and ROHS authentication.

High quality

Passed the OHSAS 18001:2007 quality system authentication and ROHS authentication.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Workshop

Our workshop

Packing Details : Wooden box

Delivery Details : 3-30 days after payment .

we are Shijiazhuang Boda Industrial Pump Co.,Ltd from china .

we mainly operates pump & pump driven equipments, pump parts & resistance wearing castings, others hydraulic machinery, accessories etc. The products contain slurry pumps, API 610 petrol-oil & chemical pumps, waters pumps which have tens of series , more than one hundred varieties , thousands of models. They are widely used in mining, metallurgy, coal mining, electric power, petroleum, chemical , water supply and drainage industry and so on. Our company have senior engineers and classic technicians, have one slurry pump factory in shijiazhuang city , one API610 pump factory in Shenyang city, one chemical pumps factory in Dalian city .

if you have any needing on pump ,or have any needing on pump Components ,please feel free contact with us . we like to offer your our best price and best service for you .

Customers and technicians discuss data

Business manager signs contract with customer

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: