- Product Details

- {{item.text}}

Quick Details

-

Rated Voltage:

-

400V

-

Rated Current:

-

1440A

-

Speed:

-

1000rpm

-

Frequency:

-

50Hz

-

color:

-

yellow

-

Control panel:

-

Com Ap

-

Engine brand:

-

JICHAI

-

Options:

-

Oil Heater

-

Gas type:

-

landfilled biogas

-

Ignition system:

-

Woodword

-

CONTROLLER:

-

Digital Control

-

Power factor:

-

0.8lagging

-

Start method:

-

24V DC Electrical Start

-

Certification:

-

CE ISO BV

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JICHAI

-

Model Number:

-

1200GF9-T2

-

Rated Voltage:

-

400V

-

Rated Current:

-

1440A

-

Speed:

-

1000rpm

-

Frequency:

-

50Hz

-

color:

-

yellow

-

Control panel:

-

Com Ap

-

Engine brand:

-

JICHAI

-

Options:

-

Oil Heater

-

Gas type:

-

landfilled biogas

-

Ignition system:

-

Woodword

-

CONTROLLER:

-

Digital Control

-

Power factor:

-

0.8lagging

-

Start method:

-

24V DC Electrical Start

-

Certification:

-

CE ISO BV

1MW/1000kw Biogas Generator/Natural Gas Generator/Syngas Generator

Product Description

This natural gas generator adopts - H16V190ZLT 2 engine, which is one sort of highly intelligent, low heat consumption, high reliability, low emission, long lifetime 16V gas engine. H16V190ZLT-2 electrical control and external mix engine owns speed 1000r/min, single unit power 1320kW.

With large power reverse, the engine can be used to assemble 1000kW natural gas generator set and equipped machinery. It owns 38% generation efficiency, low maintenance cost and yearly 8000 running hours.

Main Specification of 1200GF9-T2 Gas generator

|

Model of genset |

1200GF9-T2 |

|

Model of engine |

H16V190ZLT-2 |

|

Model of alternator |

1FC6 Series |

|

Coupling method |

Elastic coupling |

|

Rated speed(r/min) |

1000 |

|

Rated power(kW/KVA) |

1200/1500 |

|

Rated voltage(V) |

415/240 |

|

Rated current(A) |

1391 |

|

Rated frequency(Hz) |

50 |

|

Rated power factor |

0.8 lagging |

|

Voltage regulation |

Automatic |

|

Supply connecting |

3 phase 4wire |

|

Governor |

EGS-01/02 (WOODWARD) |

|

Control model |

Remote electric control, Hand control |

|

Starting method |

24V DC electric starting motor |

|

Cooling method |

Water cooling system |

|

Electrical efficiency |

38% |

|

Heat Consumption |

≤ 9500kJ/kWh |

|

Net weight(kg) |

15200 |

Requirements for fuel gas

In order to ensure its reliable and stable operation of the generator set, the requirements for the natural gas quality is as follows:

——Natural gas should be dehydrated without any water, crude oil & clean oil

——Natural gas pressure 100~400kPa;

——Natural gas temperature -20~40℃;

——Total sulfur content less than 200mg/m3.

Note: Gas volume is under standard condition with 100kPa atmosphere, 20℃ambient temperature,30% relative moisture.

Requirements for cooling water

Soften water is required by high temp and low temp engine circulation system. Cooling water should be lightly alkaline clean water without any corrosive compound, such as chloride,sulfate or acid etc.

Requirements for lubricant

Engine is equipped with complete lubrication system, with oil consumption≤0.3g/kW·h. Lubricant model: Mobil Pegasus 705 or 15W40CD.

Requirements for environment

gas generator set can run steadily, reliably, continuously under following condition: ambient temperature between -40 ℃ ~+40 ℃ ,relative moisture< 90% , sea level elevation≤2000m. The generator can output rated power under standard environmental conditions:atmosphere pressure 100kPa, ambient temperature25 ℃ , air relative moisture 30% .

1MW/1000kw Biogas Generator/Natural Gas Generator/Syngas Generator

Speed governing control system

Adopting American WOODWARD EGS control system, after special control for air and gas ratio (Gas and air compound density) with Tecjet Valve through analysis and calculation for gas and air inlet parameters and operation parameters of engine, it can reach high air and gas ratio, realize rarefied combustion, solve flash back and blasting phenomenon existing in common outer-compound engine and raise economical characteristics of engine.

EGS control system is computer intelligent and high accuracy gas control system. According to analysis and calculation, EGS gives action indication to gas control Tecjet valve and reach precision control air and gas ratio.

Adoption of single-point injection and air and gas closed-cycle technology, Through the WOODWARD-ProAct actuator, controls the flux of mixed gas; make engine operation stable and reliable.

Ignition system

Ignition system includes digital ignition module, high pressure coil, high pressure wire and spark plug, and all of them belong to famous imported products. High energy intelligent ignition module from Germany MOTORTECH MIC500 is adopted on this engine ignition.

Ignition energy is divided in three levels which can be adjusted based on gas composition to realize optimum ignition state. Ignition system owns automatic detection and alarm function for self-trouble. Once spark plug cannot ignite or occurs to short circuit or loose connection, system detects in time and alarms at once in order to maintain the generator set.

1MW/1000kw Biogas Generator/Natural Gas Generator/Syngas Generator

Gas Input and exhaust system

Applicable to low-pressure input.Generator adopts external mix before turbocharger technology. Gas pressure can only be more than 7Kpa to ensure generator set can be used widely.

Stable and efficient gas input system to ensure power generation be more effective. Gas input system adopts high-efficient air filter, high-flow turbocharger, round-pipe intercooler. The heat emission efficiency of round-pipe intercooler radiator is 20% higher than ordinary intercooler, which can satisfy cooling requirements of air flow.

Effective exhaust system protection to avoid heat radiation and hidden danger. Due to high exhaust temperature, special heat insulation layer is applied on exhaust main pipe and turbocharger surface. Expansion piece is installed on exhaust outlet to reduce fault rate and prevent releasing heat out of generator house.

Lubrication system

The lubricating method is pressure and splash lubrication, the pressure in the main oil pipe is 500 to 800 K Pa. The oil pump is outer type which is convenient to maintenance and the manual oil pump and electric pre-oiling pump is also equipped. Oil cooler and oil pressure low alarm and shutdown equipment is installed to protect the operation of genset.

Alternator system

1 0 00GF-NK biogas generator set adopts brushless excitation alternator under Siemens authority with rated voltage 400V, and rated capacity 1 250 kVA(1 000 kW) to ensure generator set can run in long and stable load.

|

Main Performance Index |

|

|

Stable voltage regulation ratio |

Single unit : ±1% s ynchronized running : ±2.5% |

|

Instantaneous voltage regulation ratio |

-15% ~ +20% UN |

|

Overload |

Run 1hour at 110% rated load ( 6hrs as cycle time ) |

|

Overcurrent multiples |

1.5IN , Time 2 minutes |

|

Short-circuit current maintaining capacity |

Excitation system can supply continuous current of three-times rated current, lasting 5s, alternator must offload.

|

1MW/1000kw Biogas Generator/Natural Gas Generator/Syngas Generator

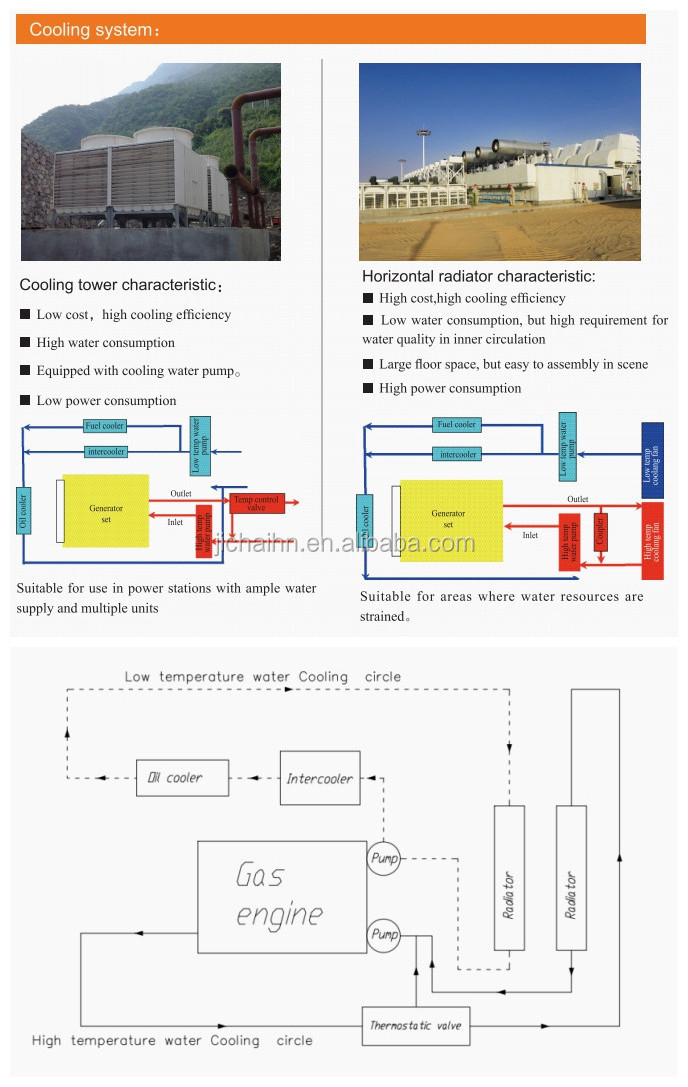

Cooling system

1 000kW Gas generator set adopts closed circulation flat bed radiator. This radiator owns low consumption and high efficiency characteristics. Shown as the above picture, this flat bed radiator is equipped with 10 fans and independent motors and consists of control system, motor driving device, electric fan, radiator and base. This control system owns air blower automatic start and stop function.

Control panel

The Control panel is floor type. Main breaker adopts auto air circuit breaker, with over-current protection and reverse-power protection. Control panel is equipped with controllers, kinds of display instruments, adjusting buttons, protection indication lamps, emergency shutdown buttons etc, to control and monitor working condition of the generator set.

It is equipped with automatic synchronization IG-NT or IC-NT (according to customers demand) with the function of automatic synchronizing and load sharing.

Factory show

Customors whole world

Successful Projects

Cetification

FAQ

1.The power range we can supply: 150kW 200kW 250kW 300kW 350kW 400kW 500kW 600kW 700kW 800kW 1000kW 1200kW 1500kW 1600kW 2000kW 3500kW 4MW.

2.what type of Gas our genset can fuel on: CNG,LNG, Natural gas,Biogas, Syngas,Biomass, Associated Gas,Well gas etc.

2.What we can do for you?

Any other questions,feel free to contact us:

Email: jichaipower(@)outlook.com

+86 182-5419-0201(Wechat/Whatsapp)