- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

6mm

-

Control Software:

-

AutoCAD

-

Place of Origin:

-

ShanDong,China

-

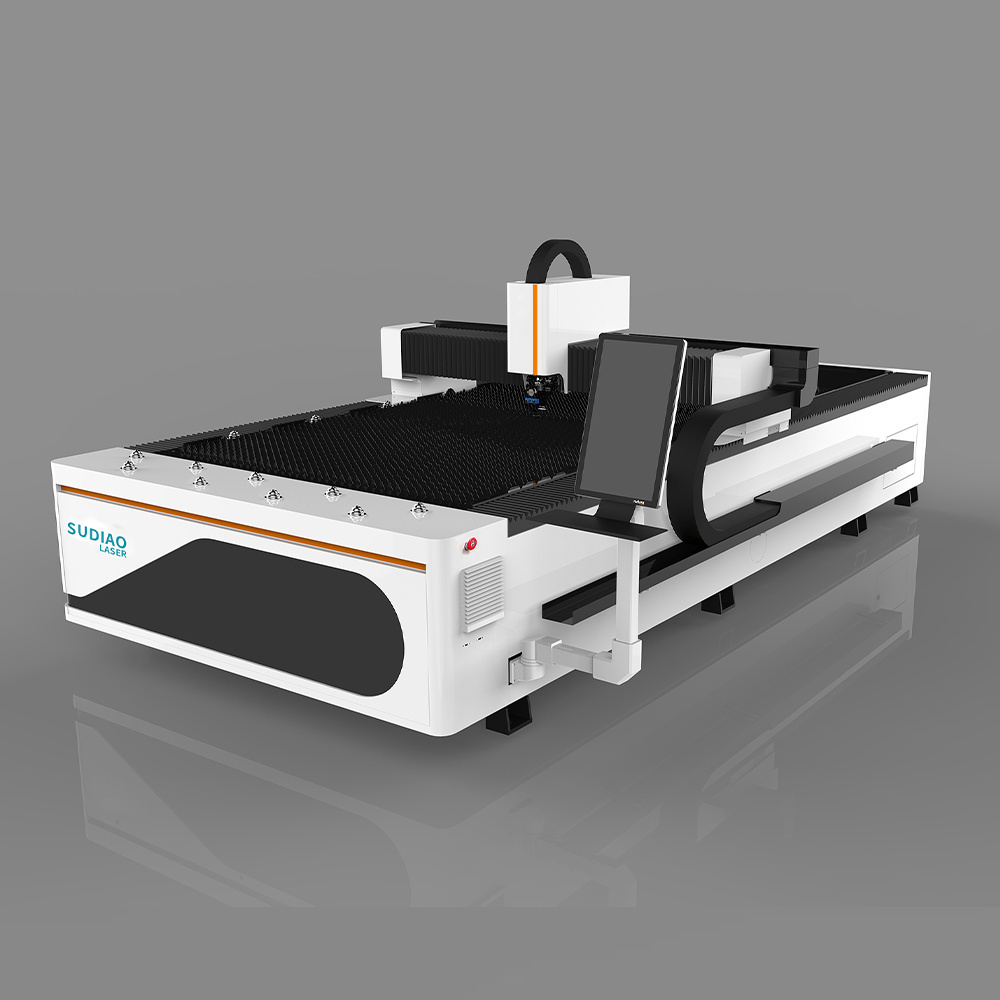

Brand Name:

-

SuDiao

-

Weight (KG):

-

3500 KG

-

Warranty:

-

3 years

-

Type:

-

Fiber Laser Cutting

-

Laser power:

-

1000W /1500W/ 2000W / 3000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Repeat positioning accuracy:

-

±0.03mm

-

Positioning accuracy:

-

0.02mm

-

Maximum speed:

-

100m/min

-

Maximum cutting speed:

-

50m/min

-

Interface:

-

USB

-

Maximum acceleratiopn:

-

1.0G

-

Power Supply Rated Voltage:

-

3-phase 380V/50Hz or Custom made

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

6mm

-

Control Software:

-

AutoCAD

-

Place of Origin:

-

ShanDong,China

-

Brand Name:

-

SuDiao

-

Weight (KG):

-

3500 KG

-

Warranty:

-

3 years

-

Type:

-

Fiber Laser Cutting

-

Laser power:

-

1000W /1500W/ 2000W / 3000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Repeat positioning accuracy:

-

±0.03mm

-

Positioning accuracy:

-

0.02mm

-

Maximum speed:

-

100m/min

-

Maximum cutting speed:

-

50m/min

-

Interface:

-

USB

-

Maximum acceleratiopn:

-

1.0G

-

Power Supply Rated Voltage:

-

3-phase 380V/50Hz or Custom made

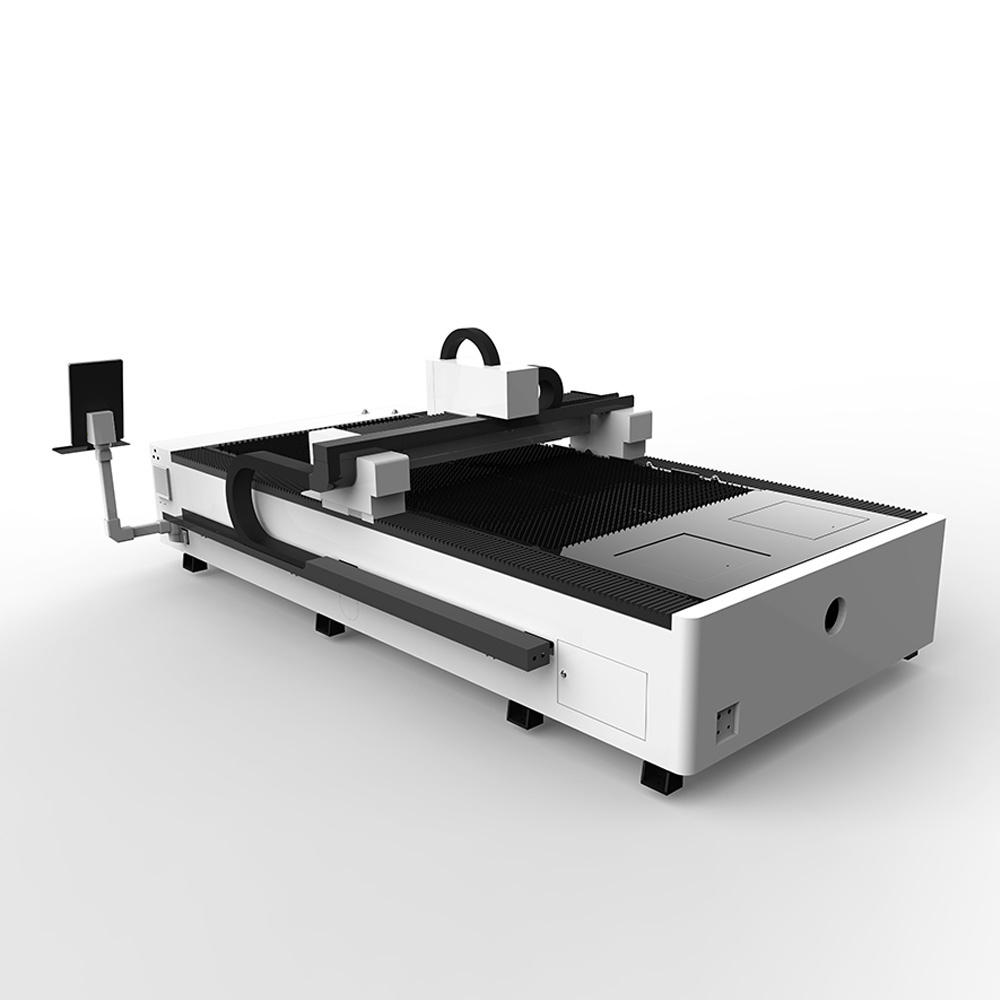

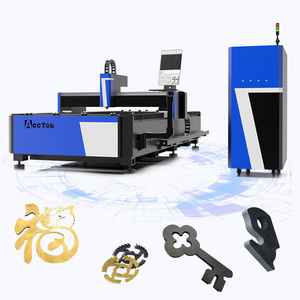

high power 1KW 2KW 3KW metal sheet and pipe laser cutting machine IPG fiber laser cutter

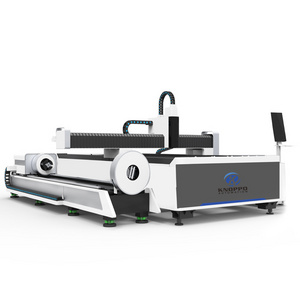

| Equipment Specification | |||||

|

Model |

RTC3015H |

RTC4015H |

RTC6015H |

RTC4020H |

RTC6020H |

|

Cutting Area |

3000*1500mm |

4000*1500mm |

6000*1500mm |

4000*2000mm |

6000*2000mm |

|

Laser source |

MAX |

MAX |

MAX |

MAX |

MAX |

|

Max Moving Speed |

100m/min,Acc=1.0G |

100m/min,Acc=1.0G |

100m/min,Acc=1.0G |

100m/min,Acc=1.0G |

100m/min,Acc=1.0G |

|

Position Accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

|

Reposition Accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

|

Power |

380V 50/60Hz 50A |

380V 50/60Hz 50A |

380V 50/60Hz 50A |

380V 50/60Hz 50A |

380V 50/60Hz 50A |

|

Max Loading(KG) |

≤4000 |

≤5000 |

≤5500 |

≤6000 |

≤6000 |

High precision machine bed

1. Fiber laser cutting machine lathe bed part completely independent research and development, by the party welding lathe bed base, through the large gantry milling machine.

2. For large machine bed we have many years of experience in processing, each machine bed will be placed 30 to 45 days after rough machining natural failure, the internal stress release completely again after finishing, ensure the machining accuracy. High strength, stability, ensuring 20 years of use without distortion.

Laser Head

1. High stability and good cutting quality,fast piercing and cutting.

2. WSX/Raytools/Precitec for choose.

Laser source

1. High Power and High Quality Laser Output.

2. IPG Raycus MAX nLight Fiber Source For Choose.

Water chiller

1.

Automatically adjust the temperature according to different working environment, no need to change settings parameters. Reduce the temperature of the laser source and the laser head through water circulation, thereby protecting these two main parts.

2. The chiller has functions such as water flow protection and water temperature protection. If the chiller is not opened or the water flow is insufficient, the laser will not be generated when the water temperature is too high, so as to protect the laser.

FUJI servo motor

1. The excellent performance of acceleration and deceleration: acceleration from -3000r/min to 3000r/min takes time 6-7ms.Long Service LifeCompact construction and low weight.

2. FUJI/Yaskawa for choose.

Guide Rail

1. The installation accuracy of the guide rail and the rack is controlled at 0.03mm to ensure the smooth operation of the gantry, thereby ensuring the cutting accuracy.

2. APEX/YYC/J&T for choose.

Control system

1. Advantech industrial computer, with professional Weihong optical fiber cutting control system, can cut metal plates well. High cutting speed and perfect cutting edge, smooth plane and exquisite texture.

2. Save the metal cutting parameters of various technologies in the computer before leaving the factory.

Control Cabinet

All the electrical components are housed and wired in a doubled-doored electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Application:

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting like stainless steel sheet, mild steel plate,

carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet, aluminum plate, copper

sheet, brass sheet, bronze plate, gold plate, silver plate, titanium plate, metal sheet, metal plate, etc.

Application Industries:

Fiber Laser Cutting Machines are widely used in manufacture billboard, advertising, signs, signage, metal letters, LED letters,

kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets

processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts,

nameplates, refrigeration machinery, agricultural machinery, food machinery, kitchen stainless steel countertops, aerospace,

railroad locomotive, auto parts manufacturing, car body processing, medical equipment, smart home, home appliances, kitchen

equipment, fitness equipment, machinery manufacturing, sheet metal processing. etc.

Questions:

Can i get some advice? or How can I get a free training?

Answer:

Click here, we will send the related details to you.

Shandong Sudiao Intelligent Equipment Co., Ltd. is a professional r & D, production and sales of laser equipment high-tech enterprises.The company has a group of top laser technology talents, established a covering China, radiation of the global sales system.The company has a standardized intelligent equipment base, committed to fiber cutting machine, intelligent robot research and development, manufacturing and sales.The equipment is widely used in advertising industry, arts and crafts gifts, precision instruments, auto parts, jewelry and other industries.We Has Imported Advanced International Technology and Production Process. Developing High Performance ,High Quality Machines to Meet the Different Customers Requirement is our Ceaseless Pursuit and Development Direction .

We Are Looking for Long Term Business Cooperation to Work Together.

FAQ

Q1:What is the cutting size of this machine?

A:1500*3000mm For plate,it also can be customized as needed.

Q2:How long is your delivery time?

A: Generally it is a week days if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to quantity.

Q3:Do you have CE document and other documents for customs clearance?

A: Yes, we have Original. At first we will show you and And after shipment we will give you CE/Packing list/Commercial Invoice/Sales contract for customs clearance.

Q4: I don’t know how to use after I receive Or I have problem during use, how to do?

A:1) We have detailed user manual with pictures and CD, you can learn step by step. And our user manual update every month for your easy learning if there is any update on machine.

2) If have any problem during use, you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/Whatsapp/Email/Phone/Skype with cam till all of your problems finished. We can also provide door service if you need.