- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

100 KG

-

Forging or Casting:

-

Forging

-

Module:

-

12-70

-

Diameter:

-

300-16000

-

Manufacturing Process:

-

Hobbing/Milling/Shapping

-

Standard:

-

ISO,AGMA,DIN,JIS,GB,

-

Heat Treatment:

-

Quenching and Tempering

-

Certificate:

-

ISO9001:2008

-

Advantage:

-

Wear Resistant

-

Drawing Format:

-

ODM/OEM

Quick Details

-

Capacity(t/h):

-

1000

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruding

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

100 KG

-

Forging or Casting:

-

Forging

-

Module:

-

12-70

-

Diameter:

-

300-16000

-

Manufacturing Process:

-

Hobbing/Milling/Shapping

-

Standard:

-

ISO,AGMA,DIN,JIS,GB,

-

Heat Treatment:

-

Quenching and Tempering

-

Certificate:

-

ISO9001:2008

-

Advantage:

-

Wear Resistant

-

Drawing Format:

-

ODM/OEM

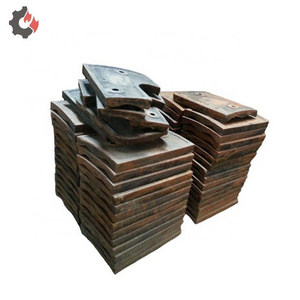

Grinding mill end cap is one of the key part of ball mill, its structure is relatively complex, long production cycle, high precision of processing and assembling, so when compiling process routes, should fully consider its manufacturability.

Ruding Steel can produce various types of ball mill end cover.

Application

Cement/ Mill and Kilns;Mining and Minerals/Rotary Dryers;Pulp & Paper/ Kilns, Debarking Drums, Drum Pulpers;Chemical / Fertilizer Industry / Food Industry

Specifications:

Ruding Steel can customize ball mill end cover as per customer's specifications and requirements

Manufacturing Process

Forging/Casting – Normalizing & Tempering – Proof Machining- Quenching & Tempering – Finish Machining

–

packaging

–

delivery.

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

Please contact us for more information and quotations.