>>

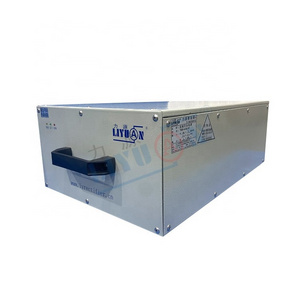

The product has a simple appearance and a reasonable structure. It is composed of multiple sets of self-developed high-frequency transformers connected in series.

>>

There are protection measures such as soft start, overvoltage, overcurrent, phase loss and overheating.

>>

The water-cooled series power supply is fully sealed, and the internal circuit board is made of acid-proof and anti-fog three-proof glue, which can be used for a long time and run stably in the highly acid-alkaline environment of the five-surface treatment industry.

>>

The whole system is equipped with advanced 485 network digital control function as standard, which can be connected to the host computer to realize automatic operation monitoring.