Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

CE

-

Supply scope:

-

Generator box+ Capacitor box+ Induction Coils (customized)

-

Max Output Power:

-

1-300kw

-

Induction Type:

-

IGBT

-

Input Voltage:

-

3 Phases 380V 50/60hz

-

Max Input Current:

-

60A

-

Cooling Method:

-

Water Cool

-

Function:

-

induction heating

-

Application:

-

heating /brazing/quenching /heardening

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WZSM

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Certification:

-

CE

-

Supply scope:

-

Generator box+ Capacitor box+ Induction Coils (customized)

-

Max Output Power:

-

1-300kw

-

Induction Type:

-

IGBT

-

Input Voltage:

-

3 Phases 380V 50/60hz

-

Max Input Current:

-

60A

-

Cooling Method:

-

Water Cool

-

Function:

-

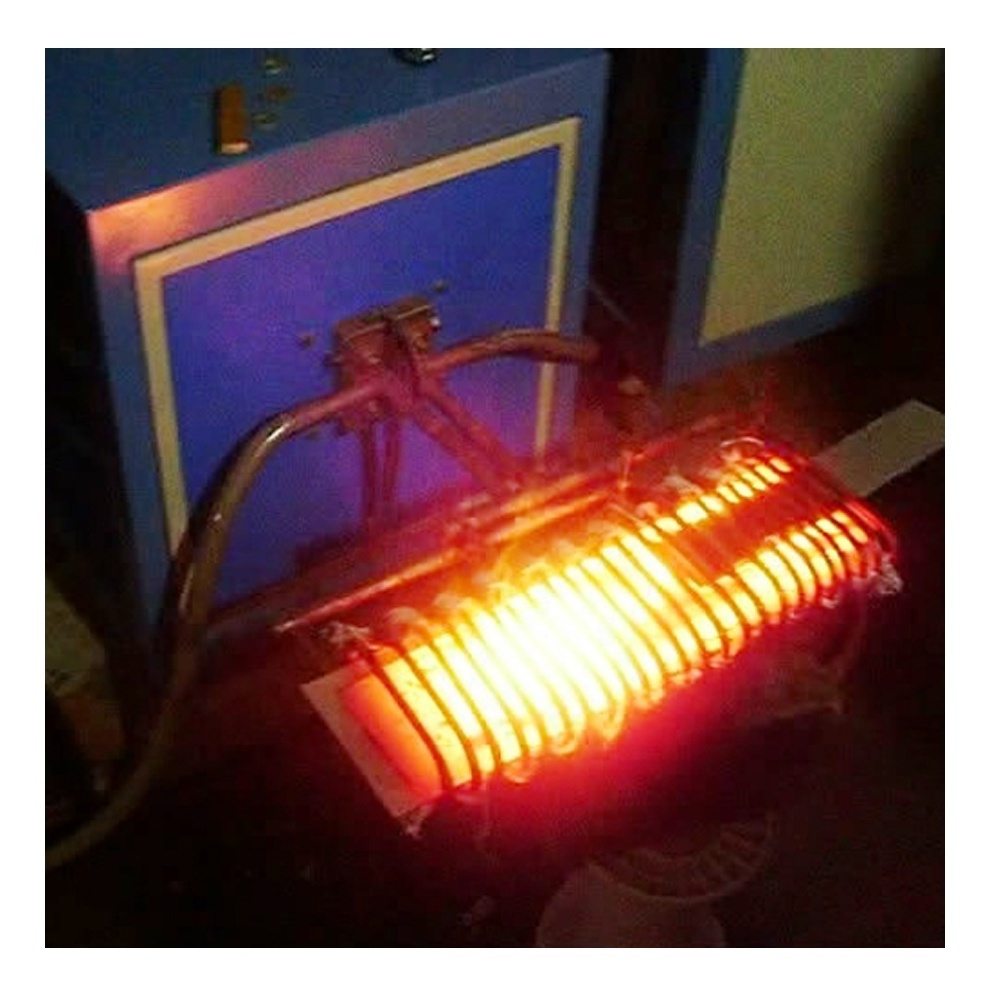

induction heating

-

Application:

-

heating /brazing/quenching /heardening

Specifications

IGBT metal induction heating equipment

1.Based on latest IGBT

3.Energy efficiency

4.Eco-Friendly

Please link our website:

http://www.cdoinduction.com/induction-heating-equipment/

to get more useful information

Skype : mandymeina

Cell phone : 0086-15168765707

Please Do not hesitate to contact us

• Heat treatment for various hardware and tools, such as plier, wrench, hammer, ax,screwing tools and shear

• Heat treatment for various automobile and motorcycle fittings, such as crankshaft,connecting rod, piston pin, chain wheel, aluminum wheel, valve, rock arm shaft,semi drive shaft, small shaft and fork.

• Heat treatment for various electric tools, such as gear and axes.

• Heat treatment for machine tools,such as lathe deck and guide rail.

• Hardening for various hardware metal parts and machined parts, such as shaft,gear chain wheel, cam,chuck and clamp etc.

• Heating for hardware molds, such as small-size mold, mold accessory and inner hole of mold.

• Annealing of various stainless steel products, such as stainless steel basin,annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

• Forging of various other metal work pieces, such as round steel, sheet/plate, pipe and others.

Brazing:

Quenching:

Forging:

|

Model |

USF-40 |

USF-50 |

USF-60 |

USF-80 |

USF-100 |

USF-120 |

USF-160 |

|

|

MAX input power |

40KW |

50KW |

60KW |

80KW |

100KW |

120KW |

160KW |

|

|

MAX input current |

70A |

85A |

105A |

150A |

185A |

220A |

260A |

|

|

Input voltage |

Three-phase 340V ~420V 50/60Hz |

|||||||

|

Oscillation frequency |

5K~40KH |

5K~30KHz |

5K~25KH |

|||||

|

Requirement of cooling water |

Hydraulic pressure |

≥0.2Mpa |

||||||

|

Flow rate |

≥6L/Min |

|||||||

|

Temperature of water |

≤45 ℃ |

|||||||

|

Generator box |

Weight |

78kg |

78kg |

78kg |

129kg |

129kg |

129kg |

139kg |

|

Volume |

72*48*92cm |

84*55*119cm |

||||||

|

Transformer box |

Weight |

37kg |

48kg |

59kg |

70kg |

80kg |

97kg |

115kg |

|

Volume |

48*41*43 |

53*41*47 |

53*44*50 |

60*43*50 |

65*43*50 |

75*47*53 |

||