- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110v/220V

-

Dimension(L*W*H):

-

48cm*29cm*18cm

-

Weight:

-

14.3 KG

-

Material:

-

Stainless Steel 304

-

Application:

-

suitable for hotels, farms and family processing agricultural products

-

Application range:

-

Squeezing oil for many kinds plant

-

Character:

-

Healthy green oil

-

Function:

-

Oil Production

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

100%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Thrive

-

Voltage:

-

110v/220V

-

Dimension(L*W*H):

-

48cm*29cm*18cm

-

Weight:

-

14.3 KG

-

Material:

-

Stainless Steel 304

-

Application:

-

suitable for hotels, farms and family processing agricultural products

-

Application range:

-

Squeezing oil for many kinds plant

-

Character:

-

Healthy green oil

-

Function:

-

Oil Production

-

Certification:

-

CE ISO

oil press manufacturer for home use,

factory price oil extraction machine for various plant seeds

Brief Introduction of oil press manufacturer for home use

Technical parameters of home use oil press manufacture

|

Model : TH-109

Outer packing size: high 350, width 560, deep 280mm

Exterior net size: 480 x 290 x x 180 mm

Weight (including packaging): 18KG

Net weight: 14.3Kg

Press speed: 7-8 kg (peanut kernel)

Maximum input power of the whole machine: 1000W

Maximum press input power: 900W

Heating power:100W

Voltage: 110V and 230V (230V specifications for domestic 220V use)

|

|

Model : TH-108

Outer packing size: high 350, width 560, deep 280mm

Exterior net size: 480 x 290 x x 180 mm

Weight (including packaging): 18KG

Net weight: 14.3Kg

Press speed: 3-4 kg (peanut kernel)

Maximum input power of the whole machine: 600W

Maximum press input power: 500W

Heating power:100W

Voltage: 110V and 230V (230V specifications for domestic 220V use)

|

A): applicable range of raw materials

Our oil press machine can be used to press:

okra, soy, Perilla seed, hemp seed shell fire, flax seed, sesame seed,

camellia seed, walnut kernel,rapeseed,sesame,white sesame,sunflower

seeds with shell, Melon seeds ,almonds, peanut seed of red/white skin ,pumpkin seeds , peanuts , pine seed kernel , coconut ,olive meat

For example Maxleaf child seed , monkey peach, hodginsii seed kernel, camphor, castor bean oil.

All t he above raw materials we have tried before, and all of them can be pressed to

extract the oil

B):We have two types of oil press machines

1,Their difference between the TH-108 and TH-109 is that the motor and

power is not the same, other aspects are the same

2,The larger the motor power , the more durable the machine

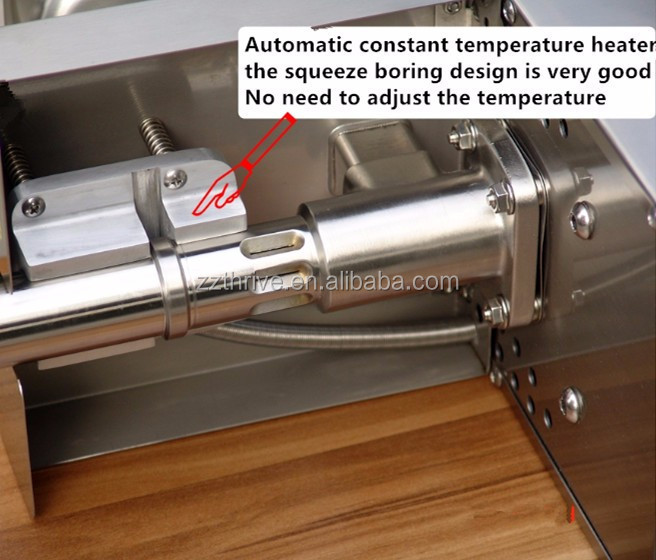

C): automatic ceramic thermostatic heater

1 ,Our machines have built-in automatic ceramic thermostatic heater ,so

it can automatic PID constant temperature without external manual adjustment

2,Dry raw materials can be directly put into the machine, do not need to be fried

3,No smoke in the oil extraction process, and raw materials can be added at any

time,no need to stop the machine to operate

D): Our squeezing boring

1,Our squeezing boring is using a secondary oil squeeze chamber technology

2,The inner structure of the pressing chamber : the middle is the octagon and the two

ends are round

3,We divided the press boring into 3 independent segments to precision casting,

with imported automatic plasma deep penetration welding, and then obtain the

whole pressing chamber

4,The inner structure of the pressing chamber of the welding enables the oil to produce two times in high pressure, the oil yield is raised to the limit

At the same time, the machine has the function of cold pressing and hot pressing

5,Poor design of the pressing chamber need to use high temperature to force out

the oil

6,And high temperature will make the color of the oil darker, so it is easy to produce

toxins

7,Our machine pressed linseed oil does not need to open heating function. oil temperature in summer in southern China under normal temperature environment of real measured low to 37.8 degrees, without damaging the plant's natural vitamin, completely retained activity of linseed oil and effective ingredients and health care effect of first-class

8,In addition to the

motor

itself comes with

a cooling system

,

the bottom of

the machine

additionally

installed

with forced

air cooling system

:

double cooling

system

to

work simultaneously

, so the machine

may be

continuous to work in

hot summer

E) : A vantages of our squeezing boring

1, The first bearing will completely remove the Recoil force that produced by the

Press boring At the same time be the interval barrier of the first wave of food area and power area

2,The second bearing provide stable power shaft rotational positioning, built-in O - shaped

closed loop, and will be the third barrier for food area and power area

3, The 8 cm distance between two bearings to separate food section and the connection of

mechanical power area, form a barrier for the second time

4, Three layer plate provides strong mechanical strength, make the Recoil force of the Press boring and the Bearing capacity of motor gear box completely independent ,

so that the service life of the gear box can get the maximum guarantee

F ): Advanced welding technology

We use the original imported high-speed plasma automatic welding machine for automatic welding of the chamber, do not change the original characteristics of the metal.

To make the machine work more reliable and anti - Corrosion in high pressure

environment, and it can keep the integrity and conform to the design requirements

of the industrial products

G): Easy to clean

The pressing boring is easy to clean, you just need remove 4 screws , It is very easy,

and even do not have to clean",There is no hard place to clean

H): High oil yield and hjigh o il quality

1,Diesel thinner, squeezed more clean, the higher oil yield

The thickness of the greaves is just 0.16mm that pressed by our machine

2,Sink in the bottom of the thing is just the fine foam of the raw material of the oil

that pressed by our machine, not be destroyed by high temperature, keep the the

original flavor of the raw material , pure nature, can eat.Cold pressed peanut oil is

transparent golden yellow

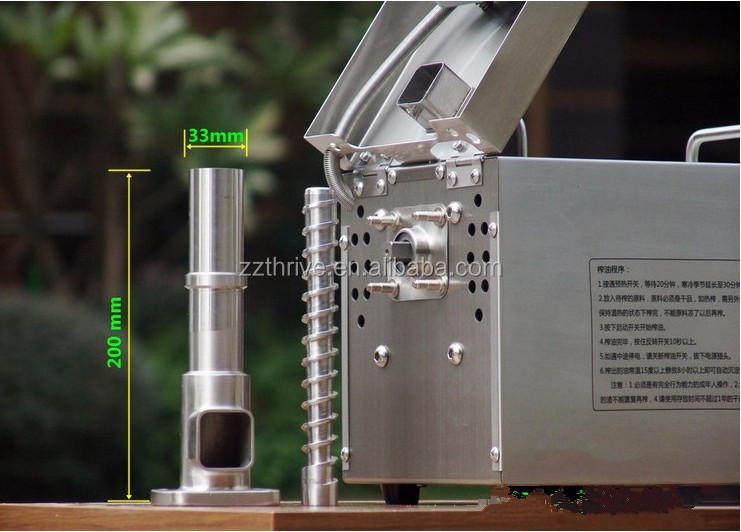

I):S tandard configuration of oil press bar

1,According to the actual use of customers for many years, we finally selected

imports of wear-resistant tool steel to manufacture

2,Tool steel can be magnets, but it will not rust, as imports of stainless steel kitchen

chopping knife

The press bar made by steel can achieve our design requirements of more than 10 years of life expectancy

3,In addition, in order to facilitate the preferences of different customers, Otherwise

we import pure 304 stainless steel screw press ed bar for customer choice

It is not a magnet for adsorption, but it is easy to wear and tear, only suitable for

peanutsesame seeds and the like without shell of soft materials

J) : Standard Specification for plugs

K):Pure 304 stainless steel cylinder

L): Our motor

We use the industrial motor which has very excellent sealing properties and can

ensure the grease inside not on the outward leakage of edible oil pollution, also

not let outside any dust or liquid infiltration of internal damage precision gear system. Therefore, squeeze the oil health without pollution

Package : Our machines are packed in standard uniform export cases. This case is very strong and can ensure that the product will not be damaged

Delivery time : Under normal circumstances ,We will send automatic oil press machine within 3-15 working days after receiving the down payment

Pre-sale service

1,Recommend the most suitable machine for customers,e specially according

customers demand

2 , Strictly control easy production line and easy parts,to ensure machine quality

3 every machine is tested before delivery,to ensure machine function well

After-sale service

1,one year warranty

2,lifelong free technical support and spare parts support

3,Help customers solve problem rapidly

Warranty

1, Malfunctions which are caused by machine-self and quality will be responsible for our manufac

2,Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self