- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TIANYUE

-

Model Number:

-

TY-LMD-600

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

4680*1650*1850

-

Weight:

-

3100 KG

-

Product name:

-

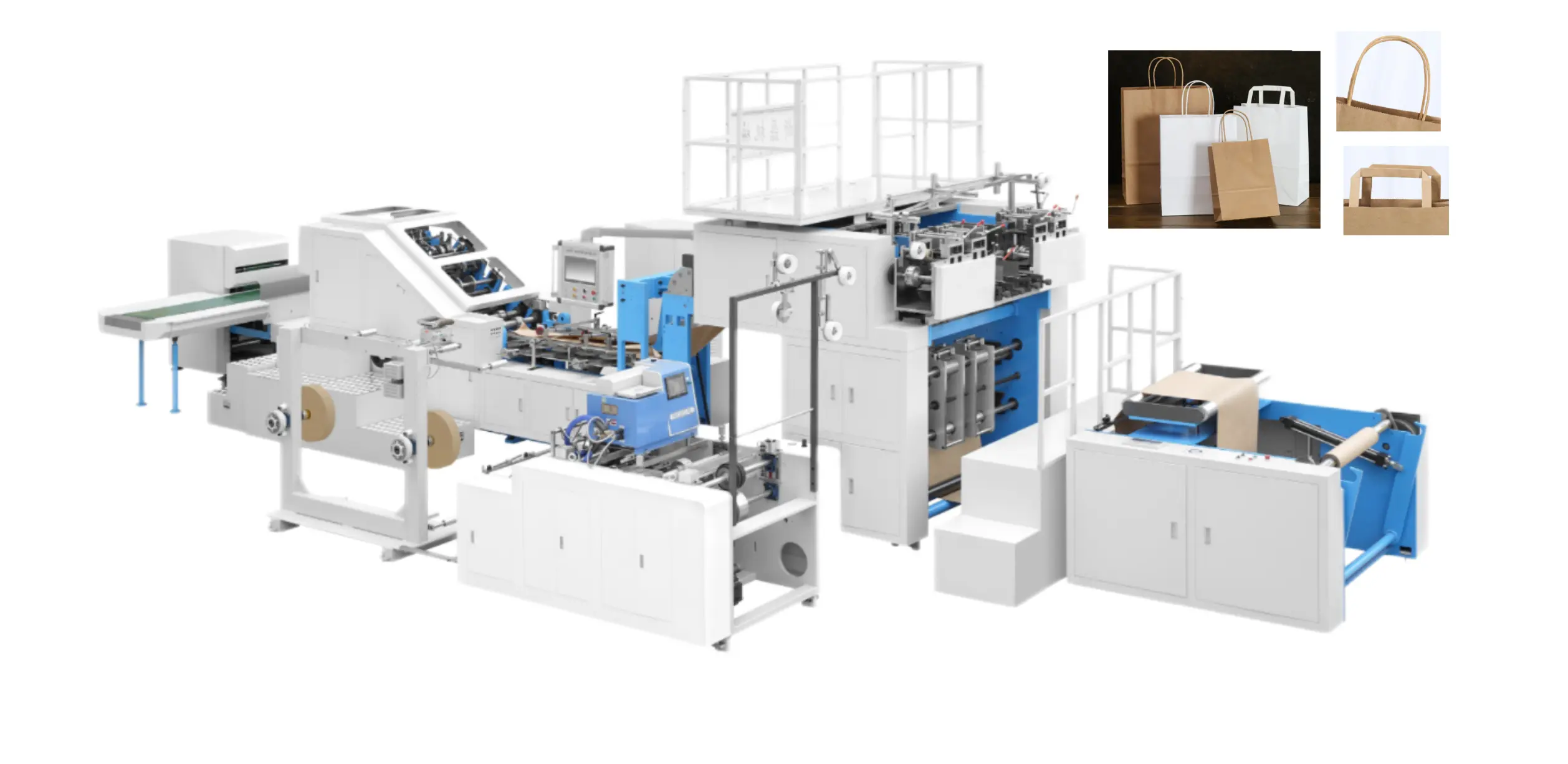

Automatic Handle Kraft Paper Bag Making Machine

-

Max.Speed:

-

400 pcs/min

-

Paper Thickness:

-

30-80 gsm

-

Paper Roll Width:

-

220-700 mm

-

Max.Roll Diameter:

-

1000 mm

-

Usage:

-

paper bag

-

Color:

-

Customer Requirement

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TIANYUE

-

Model Number:

-

TY-LMD-600

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

4680*1650*1850

-

Weight:

-

3100 KG

-

Product name:

-

Automatic Handle Kraft Paper Bag Making Machine

-

Max.Speed:

-

400 pcs/min

-

Paper Thickness:

-

30-80 gsm

-

Paper Roll Width:

-

220-700 mm

-

Max.Roll Diameter:

-

1000 mm

-

Usage:

-

paper bag

-

Color:

-

Customer Requirement

Products Description

|

Type

|

|

TYFD-220/TYFD-350/TYFD-450 square bottom paper bag machine

|

|

|

|||

|

Cutting Length(C)

|

|

150-460 mm

|

|

230-625 mm

|

|||

|

Bag Length(H)

|

|

145-455 mm

|

|

225-620 mm

|

|||

|

Bag Width(L)

|

|

70-280 mm

|

|

|

|||

|

Gusset Depth(S)

|

|

0-50 mm

|

|

|

|||

|

Standard Flap(P)

|

|

12-20 mm

|

|

|

|||

|

Max.Speed

|

|

400 pcs/min

|

|

|

|||

|

Paper Thickness

|

|

30-80 gsm

|

|

|

|||

|

Paper Roll Width

|

|

220-700 mm

|

|

|

|||

|

Max.Roll Diameter

|

|

1000 mm

|

|

|

|||

|

Reel Inner Diameter

|

|

76 mm

|

|

|

|||

|

Printing Color

|

|

4 Color

|

|

|

|||

|

Printing Width

|

|

720 mm

|

|

|

|||

|

Printing Length

|

|

200-800 mm

|

|

|

|||

|

Max.Printing Speed

|

|

80 m/min

|

|

|

|||

|

Overprint Precision

|

|

±0.2 mm

|

|

|

|||

|

Thickness of Plate

|

|

2.28 mm

|

|

|

|||

|

Total Power

|

|

9 kw

|

|

|

|||

|

Weight of Machine

|

|

4500 kg

|

|

4600 kg

|

|||

|

Overall Dimension(LxWxH)

|

|

7600×1650×1850 mm

|

|

7700×1650×1850 mm

|

|||

1. The human-machine touch screen interface, the work condition can be shown in real-time

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3. Material lifting adopt pneumatic lift structure.

4. Automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

6. Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Don't stop machine adjust double bottomstructure, the adjustment will become moreintuitive,

more simple, more time saving.

8. Glue roller air defense coating control, avoidgluing on besmear brushs hub surface directly,

9. Accurate color tracking system, color errorsautomatically shut down.

10. Automatic lubricating oil supply system,reduce unnecessary trouble.

Main Product

About Us

Production Process

Our Certificate

Our Customers

Logistics Mode

FAQ

Q1: Are you a factory or trading company

A1: We are a factory, we can guarantee our price is first-hand, very cheap and competitive.

Q2: How does your factory do regarding quality control?

A2: All the products will be 100% checked before the shipment.48hours running without stop to confirm no problem.

Q3: What is your payment term ?

A3:Payment: by bank T/T payment. 30% down payment, and balance for 70% payment before shipment,

Delivery time: within 45 working days after receiving the deposit.

Q4: How about warranty?And after sales ?

A4: From the day of the use of the machine in the buyer's factory: 1year. The seller guarantees the mc are 100% new.

The above clause is only effective being properly used, any artificial misuse or destroy prepensely is not within the limit of quality.

Q5: What do you have to tell us before buying?

A5: If the buyer need seller's engineer to go to his factory to help install and test the mc, please be kindly bear their visa,

go and return ticket, lodging and eating, salary us$100/ per day. But this can be negotiated by both side.

Hot Searches