- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BARUI

-

Model Number:

-

BRPP

-

Voltage:

-

380v/50hz

-

Power:

-

12-24KW

-

Dimension(L*W*H):

-

40HQ Container

-

Weight:

-

30-150Tons

-

Certification:

-

CE ISO

-

Name:

-

Heavy fuel oil Mazut fractional distillation/diesel making machine

-

Application:

-

Waste Oil Refinery Equipment

-

Type:

-

Continuous Oil Distillation Machine

-

Material:

-

Q235R/Q345R Boiler Steel&S.S.304/316L

-

Raw material:

-

Crude Oil&Used Engine Oil&Waste Oil

-

Capacity:

-

5-100Ton/Day

-

End product:

-

Gasoline&Diesel

-

Function:

-

Oil Refining

-

Advantags:

-

Energy Saving&Environmentally Feiendly

-

Heating Method:

-

Indirect

Quick Details

-

Flow:

-

50L/min -300L/min

-

Working Pressure:

-

Normal Pressure

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BARUI

-

Model Number:

-

BRPP

-

Voltage:

-

380v/50hz

-

Power:

-

12-24KW

-

Dimension(L*W*H):

-

40HQ Container

-

Weight:

-

30-150Tons

-

Certification:

-

CE ISO

-

Name:

-

Heavy fuel oil Mazut fractional distillation/diesel making machine

-

Application:

-

Waste Oil Refinery Equipment

-

Type:

-

Continuous Oil Distillation Machine

-

Material:

-

Q235R/Q345R Boiler Steel&S.S.304/316L

-

Raw material:

-

Crude Oil&Used Engine Oil&Waste Oil

-

Capacity:

-

5-100Ton/Day

-

End product:

-

Gasoline&Diesel

-

Function:

-

Oil Refining

-

Advantags:

-

Energy Saving&Environmentally Feiendly

-

Heating Method:

-

Indirect

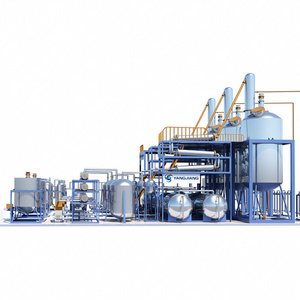

HENAN BARUI Heavy Fuel Oil Mazut Fractional Distillation/Diesel Making Machine with Advanced Technology

Henan BARUI oil vertical vacuum distillation column is a newly developed product which combines dozens of our latest technologies.Its process flow is that cold raw oil is heated with the top part of the distillation column and then dehydrated in the dehydration column. Then it is heated in the heating furnace. When raw oil is heated to the desired temperature, it will go into the distillation tower.

The distillation unit is a self-diverging atmospheric pressure distillation unit, and it uses a semi-continuous distillation process to refine the waste oil under negative pressure.

This kind design is able to rapidly extract light and heavy distillates from different fractions by given different temperatures control.

The equipment has the following advantages:

(1)

energy saving

;

(2)

cost saving

;

(3)

Easy to operate,low operation cost

, only 1-2 workers can control the machine;

(4)

Environmental friendly

;

(5)

High recycling rate

;

(6) Efficient vacuum systems;

(7) High efficiency safety devices;

(8)

High quality refined oil

, no any discoloration caused by oxidation, no any bad smelling.

Heat Exchanger

In the heat exchanger, flue gas and crude oil act as the media to save energy.

Heating Furnace

Comparing with tube heating furnace, this furnace can reach higher process temperature, more than 600 degree Celsius.

De-dusting Tower

1. Energy saves;

2. Low production cost.

Distillation Tower

This kind distillation tower has high efficiency packings and proper tower internals which has strong ability to remove impurities and dehydrate.

High Temperature Gas-liquid Separator

After separation, water content is less than 1%, that can meet the industrial production requirement.

Oil Tank

The vertical design is good for conducting the non-condensed gas.

Residue Tank

The tank is a horizontal tank, and the sight glass and vessel body is of high temperature resistance.

Condenser

Vertical condenser can prevent the oil gathering, so that can guarantee cooling efficiency.

HENAN BARUI ENVIRONMENTAL PROTECTION EQUIPMENT CO.LTD

Honesty is our first principle in international trade. BARUI pay more attention to technology improvement, environmental protection, security in production and professional service, Looking forward to have further cooperation with you !!!

We are a team with expertise and an attitude of absolute responsibility.

A team of professional designers

Based on professional knowledge theory, professional team designers are in a serious and responsible attitude to constantly create more new quality products.

premium product

Display of quality products

The display of high quality product can help customers quickly find the products they need and get the product information.

24 hours services

We are on line 24 hours for questions about the product. Please contact me for any questions!

Customers Visit to Our Factory

Simulation Operation Demonstration

Explain to the client in detail and Negotiate with Customers

Welcome to contact me, 24 hours service!