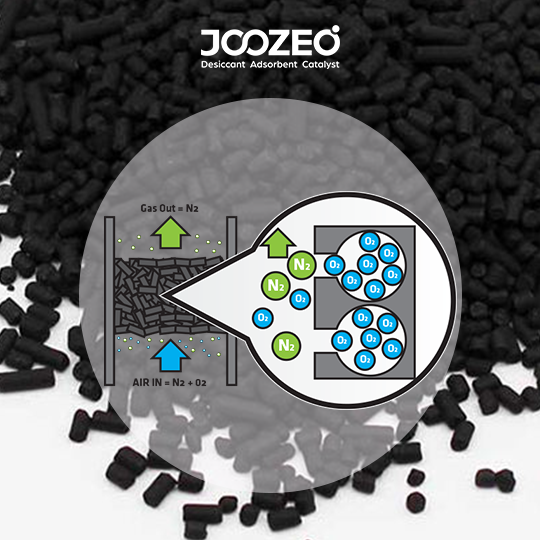

Used to separate N2 and O2 in the air in the PSA system.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JOOZEO

-

Model Number:

-

cms-200/CMS-220/CMS-240/CMS-260, CMS-220 CMS-240 CMS-260 CMS-280 CMS-300

-

Certification:

-

ISO9001:2008

-

Appearance:

-

Granule

-

Color:

-

Pure Black

-

Packing:

-

drum

-

MOQ:

-

20kg

-

Application:

-

nitrogen generator

Quick Details

-

CAS No.:

-

7440-44-0, 7440-44-0

-

Purity:

-

99.9%, 99.9%-99.999%

-

Other Names:

-

CMS

-

MF:

-

C

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JOOZEO

-

Model Number:

-

cms-200/CMS-220/CMS-240/CMS-260, CMS-220 CMS-240 CMS-260 CMS-280 CMS-300

-

Certification:

-

ISO9001:2008

-

Appearance:

-

Granule

-

Color:

-

Pure Black

-

Packing:

-

drum

-

MOQ:

-

20kg

-

Application:

-

nitrogen generator

Products Description

Carbon Molecular Sieve

JZ-CMS

JZ-CMS is mainly composed of element carbon.

Specification

|

Type

|

Adsorbent pressure

|

N2 purity

|

N2Capacity

|

Air / N2

|

|

|

(Mpa)

|

%

|

(NM3/h.t)

|

|

|

JZ-CMS2N

|

0.75-0.8

|

95

|

380

|

1.75

|

|

|

|

97

|

340

|

2.0

|

|

|

|

98

|

260

|

2.25

|

|

|

|

98.5

|

255

|

2.29

|

|

|

|

99

|

245

|

2.38

|

|

|

|

99.5

|

220

|

2.55

|

|

JZ-CMS4N |

0.75-0.8

|

98.5

|

275

|

2.25

|

|

|

|

99

|

260

|

2.35

|

|

|

|

99.5

|

240

|

2.5

|

|

|

|

99.9

|

155

|

3.5

|

|

|

|

99.99

|

110

|

4.65

|

|

|

|

99.999

|

65

|

6.7

|

|

JZ-CMS6N

|

0.75-0.8

|

99

|

320

|

2.2

|

|

|

|

99.5

|

260

|

2.5

|

|

|

|

99.9

|

175

|

3.5

|

|

|

|

99.99

|

120

|

4.6

|

|

|

|

99.999

|

70

|

6.7

|

Application

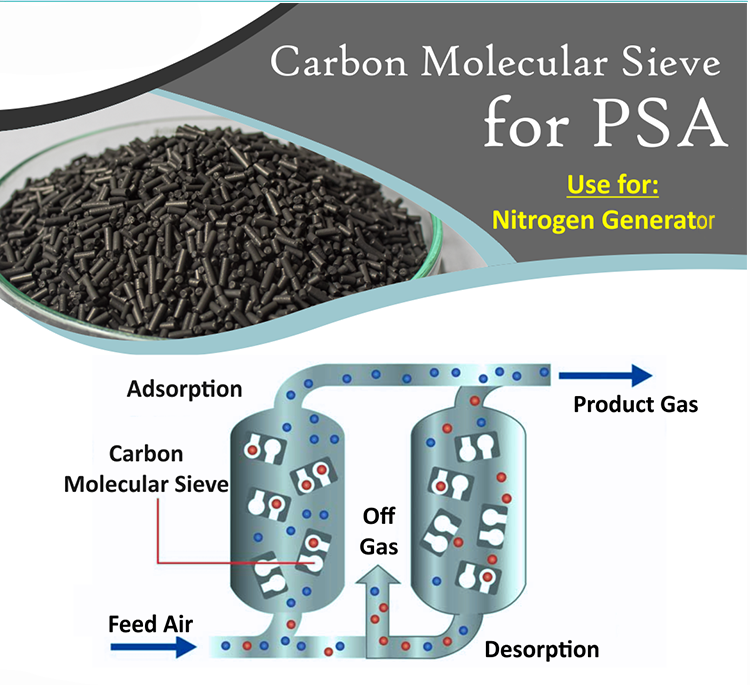

Nitrogen generator is a nitrogen production equipment designed and manufactured according to the PSA technology. Nitrogen generator use carbon molecular sieve (CMS) as adsorbent. Usually use two adsorption towers in parallel, control the inlet

pneumatic valve automatically operated by the inlet PLC, alternately pressurized adsorption and decompressing regeneration, complete nitrogen and oxygen separation, to obtain the required high purity nitrogenThe raw materials of carbon molecular sieve are phenolic resin, pulverized first and combined with the base material, then activated pores. PSA technology separates nitrogen and oxygen by the van der Waals force of carbon molecular sieve, therefore, the larger the surface area, the more uniform the pore distribution, and the more the number of pores or subpores, the adsorption capacity is bigger.

Attention: The product as desiccant cannot be exposed in the open air and should be stored in dry condition with air-proof package.

pneumatic valve automatically operated by the inlet PLC, alternately pressurized adsorption and decompressing regeneration, complete nitrogen and oxygen separation, to obtain the required high purity nitrogenThe raw materials of carbon molecular sieve are phenolic resin, pulverized first and combined with the base material, then activated pores. PSA technology separates nitrogen and oxygen by the van der Waals force of carbon molecular sieve, therefore, the larger the surface area, the more uniform the pore distribution, and the more the number of pores or subpores, the adsorption capacity is bigger.

Attention: The product as desiccant cannot be exposed in the open air and should be stored in dry condition with air-proof package.

JOOZEO Strength

Shanghai Jiuzhou Chemicals Co., Ltd. was established in 2002. The company has two production bases, which are a company integrating R&D, production and sales. The Shanghai production base is located in Jinshan Second Industrial Zone, covering an area of 21,000 square meters; The Wuxi production base is located in Wuxi Liandong U Valley. Company has many utility model patents such as "Alumina Manufacturing System and Manufacturing Process" and "Belt Dryer Air Intake and Exhaust System"

1、Quality control

3+ independent laboratory

7+ routine inspections

2 years retention management for checking

Passed ISO, TUV system certifications

2、Dynamic Data

Dynamic data monitoring

Accurate product ratio

Complete plan development

Remote auxiliary debugging

3、Program Recommendation

20+years manafacturer ablity

15+years export experience

Cooperation with 60+ countries

Years of application experience

4、Supporting Services

Pre-sales:

Help you find most suitableproduct with different application

In-sales:

ERP system used to make product traceable.samples reserved for 2+ yearsincase anydispute

After-sales:

Response within 24 hours for any problem

|

Q1: What's your production capacity?

A1: We can make 3,000 ton one month. If you have order plan, feel free to contact me, I will tell you delivery time according to your demand.

|

|

Q2: Do you have a catalogue? Can you send me the catalog to check all your products?

A2: Yes, We have product catalogue. Please contact us for catalog.

|

|

Q3: How can we guarantee quality?

A3: Always a pre-production sample before mass production;Always final Inspection before shipment;

|

|

Q4: What about your delivery time?

A4: The delivery time should contract us and our salemen will tell you the delivery time

|

|

Q5: Why should you buy from us not from other suppliers?

A5: We have 20 years of professional experience in the production of Molecular sieve and other catalyst or absorbent, solid foundation, rich experience, with a complete and scientific quality management system.

|

Hot Searches