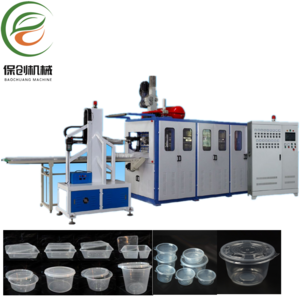

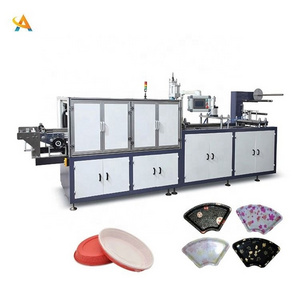

1. High production capacity: one machine can produce 1440 pcs 1000ml boxes per hour.

2.

Excellent stability:

30 years of dedication, crafting high-quality injection molding machines with precision and expertise.

3.

Energy-efficient with servo motor drive, all actions are demand-driven, ensuring exceptional energy savings.