- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

tengao

-

Voltage:

-

220/380V

-

Power:

-

12kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

1400*780*1530mm

-

Application:

-

Yogurt

-

Name:

-

Yogurt Make Machine

-

Final product:

-

Yougurt

-

Product name:

-

Dairy Yogurt Making Milk Pasteurization Machine

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

tengao

-

Voltage:

-

220/380V

-

Power:

-

12kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

1400*780*1530mm

-

Application:

-

Yogurt

-

Name:

-

Yogurt Make Machine

-

Final product:

-

Yougurt

-

Product name:

-

Dairy Yogurt Making Milk Pasteurization Machine

Product descriptions from the supplier

Food Grade Yogurt Production Line / Milk Processing Plant Unit / Yogurt Processing Machine

Yogurt is a sweet and sour milk drink. It is a milk product that uses milk as a raw material.

After pasteurization, beneficial bacteria (leavers) are added to the milk.

After fermentation, it is cooled and filled. Most yogurt products on the market are solidified, stirred, and fruity with various fruit juices and jams.

Yogurt Production Line Introduction:

After the raw milk is pre-treated and cooled to the inoculation temperature, the starter is continuously pumped into the

fermentation tank.

fermentation tank.

After the tank is full, start stirring for a few minutes to ensure that the starter is evenly dispersed.

The fermentor is insulated to maintain a constant temperature throughout the incubation period.

In order to check the acidity development in the tank, a pH meter can be installed on the tank. The culture time of stirred yogurt was 2.5-3h, 42-43 ℃, and the

ordinary starter was used (inoculation amount was 2.5-3%).

In order to obtain the best product, the fermentation must be stopped when the pH reaches the ideal value,and the temperature of the product should be cooled from 42-43 ℃ to 15-22℃ within 30 minutes.

At the same time, in order to ensure the ideal viscosity of the finished product, the mechanical treatment of the clot must be gentle.

At the same time, in order to ensure the ideal viscosity of the finished product, the mechanical treatment of the clot must be gentle.

Cooling is carried out in the plate heat exchanger with special plates, which can ensure that the product is not subject

to strong mechanical disturbance.

to strong mechanical disturbance.

After cooling to 15-22 ℃, the yogurt is ready for packaging. Fruits and spices can be added during the transportation of yogurt from buffer tank to packaging machine.

This is through a variable speed metering pump to continuously beat these ingredients into the yogurt, after mixing device. The design of the mixing device is static and hygienic, and ensures that the fruit and yogurt are thoroughly mixed.

The fruit metering pump and the yogurt feeding pump operate synchronously.

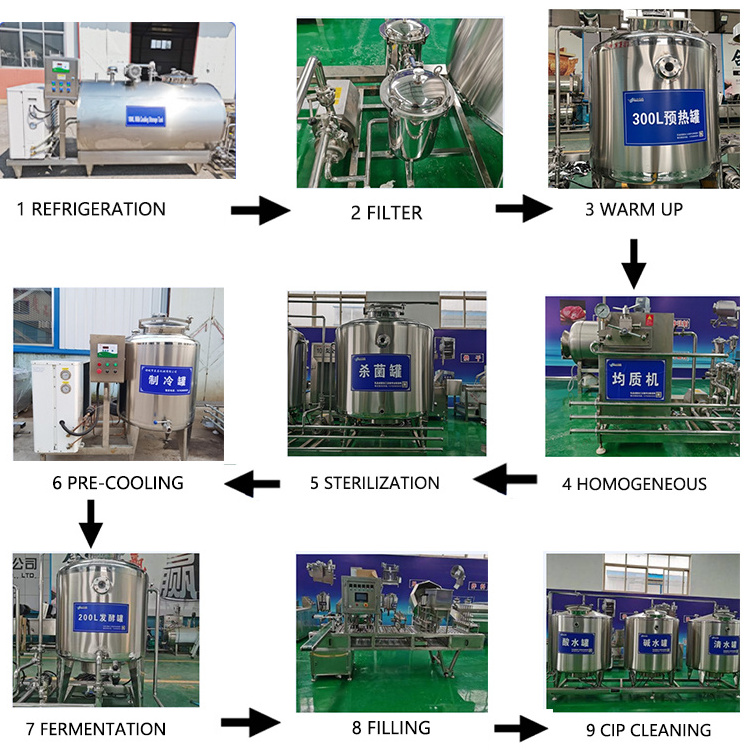

Process:

Raw milk → Filtration → Preheating → Homogenization → Stirring sterilization → Fermentation → Refrigeration → Filling.

Matching equipment:

Raw milk → Pump → Filter → Pump → Preheat tank → Pump → Homogenizer → Pump → Whisk tank → Pump → Fermenter→Pump → Refrigeration tank → CIP cleaning system.

Details Images

Cooling Tank:

Material: SUS304

Power supply: 380v/50Hz

Total power: 2Kw

Cooling capacity: 5000 kcal/hour

Sheet thickness: inner 2mm middle 1mm outer1.2mm

Installation size: 1700*1100*1950mm

Refrigeration medium: R22

Thermal insulation performance: ≤1℃/3H

Material: SUS304

Power supply: 380v/50Hz

Total power: 2Kw

Cooling capacity: 5000 kcal/hour

Sheet thickness: inner 2mm middle 1mm outer1.2mm

Installation size: 1700*1100*1950mm

Refrigeration medium: R22

Thermal insulation performance: ≤1℃/3H

Compressor:2P

Motor power/quantity: 0.75kw/1

Insulation material/thickness: polyurethane foam/50mm

Material inlet and outlet diameter: Φ32mm/Φ38mm

Motor power/quantity: 0.75kw/1

Insulation material/thickness: polyurethane foam/50mm

Material inlet and outlet diameter: Φ32mm/Φ38mm

Preheating tank:

Material: SUS304 Power supply: 380v 50Hz

Power: 9kw

Thickness of heavy plate: inner 2mm middle 2mm outer 1.2mm

Installation size:1020*870*1530mm

Power of stirring motor: 0.55kw

Stirring speed: 36r/min

Working pressure: 0.09 Mpa

Maximum temperature: the boiling point of the liquid at the local pressure

Material inlet and outlet diameter: Φ32mm/Φ38mm

Material: SUS304 Power supply: 380v 50Hz

Power: 9kw

Thickness of heavy plate: inner 2mm middle 2mm outer 1.2mm

Installation size:1020*870*1530mm

Power of stirring motor: 0.55kw

Stirring speed: 36r/min

Working pressure: 0.09 Mpa

Maximum temperature: the boiling point of the liquid at the local pressure

Material inlet and outlet diameter: Φ32mm/Φ38mm

Homogenizer:

Output: 200L/H Maximum pressure: 25Mpa

Motor power: 4kw

Dimensions: 990*600*850mm

Whole machine weight: 600kg

Pump body material: 1Cr18Ni9Ti

Lubrication method: splash lubrication

Gear form: hardened helical gear

Crankshaft material: 45# steel, surface

hardened processing Plunger material: 9Cr18

Plunger diameter and frequency: 20mm, about 210 times/min

Plunger sealing material: V-shaped cloth clip ring

Check valve structure: cone valve

Check valve material: special steel treatment

Homogeneous rod and seat material: special hard alloy

Output: 200L/H Maximum pressure: 25Mpa

Motor power: 4kw

Dimensions: 990*600*850mm

Whole machine weight: 600kg

Pump body material: 1Cr18Ni9Ti

Lubrication method: splash lubrication

Gear form: hardened helical gear

Crankshaft material: 45# steel, surface

hardened processing Plunger material: 9Cr18

Plunger diameter and frequency: 20mm, about 210 times/min

Plunger sealing material: V-shaped cloth clip ring

Check valve structure: cone valve

Check valve material: special steel treatment

Homogeneous rod and seat material: special hard alloy

Pasteurizer:

Material: SUS304 Power supply: 380v 50Hz

Power: 9kw T

hickness of heavy plate: inner 2mm, middle 2mm, outer 1.2mm Installation

size: 1020*870*1530mm

Stirring motor: 0.55kw

Stirring speed: 36r/min

Working pressure: 0.09 Mpa

Maximum temperature: the boiling point of the liquid at the local pressure

Material inlet and outlet diameter: Φ32mm/Φ38mm

Material: SUS304 Power supply: 380v 50Hz

Power: 9kw T

hickness of heavy plate: inner 2mm, middle 2mm, outer 1.2mm Installation

size: 1020*870*1530mm

Stirring motor: 0.55kw

Stirring speed: 36r/min

Working pressure: 0.09 Mpa

Maximum temperature: the boiling point of the liquid at the local pressure

Material inlet and outlet diameter: Φ32mm/Φ38mm

Duplex filter:

Filtering capacity: 5t/h Applicable temperature: ≤120℃

Filter aperture: 200 mesh

Working pressure: ≤0.2MPa

Filter material: 304 stainless steel

Filtration accuracy: 200 (mesh/in)

Filtering capacity: 5t/h Applicable temperature: ≤120℃

Filter aperture: 200 mesh

Working pressure: ≤0.2MPa

Filter material: 304 stainless steel

Filtration accuracy: 200 (mesh/in)

Fermenter:

Material: SUS304 Power supply: 380v 50Hz

Power: 9kw

Thickness of heavy plate: inner 2mm, middle 2mm, outer 1.2mm

Installationsize: 1400*1400*1950mm

Stirring motor: 0.55kw

Stirring speed: 36r/min

Working pressure: 0.09 Mpa

Maximum temperature: the boiling point of the liquid at the local pressure

Material inlet and outlet diameter: Φ32mm/Φ38mm

Material: SUS304 Power supply: 380v 50Hz

Power: 9kw

Thickness of heavy plate: inner 2mm, middle 2mm, outer 1.2mm

Installationsize: 1400*1400*1950mm

Stirring motor: 0.55kw

Stirring speed: 36r/min

Working pressure: 0.09 Mpa

Maximum temperature: the boiling point of the liquid at the local pressure

Material inlet and outlet diameter: Φ32mm/Φ38mm

Filling Machine:

Material: SUS304 Working method: continuous work

Filling method: automatic filling

Equipment size: 1300*1300*1750mm

Material: SUS304 Working method: continuous work

Filling method: automatic filling

Equipment size: 1300*1300*1750mm

Acid/Alkali/Water Tank:

Water tank capacity: 500L Alkali tank capacity: 500L

Acid tank capacity: 500L

Pump power: 1.5kw

Equipment weight: 500kg

Dimensions: 4000*900*2300mm

Water tank capacity: 500L Alkali tank capacity: 500L

Acid tank capacity: 500L

Pump power: 1.5kw

Equipment weight: 500kg

Dimensions: 4000*900*2300mm

Company Show And Certificate

Customer Reviews

Our Services

Packaging & Shipping

FAQ

Question 1: Are you manufacturer? What are your advantages?

Yes. We are manufacturer with more than 10 years' production experience. We provide customer high quality equipment machine products at very reasonable price.

Question 2: Do you accept OEM, ODM order?

Yes. We can customize machines according to customers special requirements.

Question 3: What payment terms do you accept?

TT, LC, etc.,

Question 4: Does your machine have warranty time?

Yes. One Year.

Question 5: What’s your Minimum Order Quantity?

Any small order quantity is warmly welcomed.

Question 6: What sea port do you ship at?

Any port of China is OK.

Question 7: Can I get spare parts from your factory?

Yes. We provide spare parts according to your machine needs.

Yes. We are manufacturer with more than 10 years' production experience. We provide customer high quality equipment machine products at very reasonable price.

Question 2: Do you accept OEM, ODM order?

Yes. We can customize machines according to customers special requirements.

Question 3: What payment terms do you accept?

TT, LC, etc.,

Question 4: Does your machine have warranty time?

Yes. One Year.

Question 5: What’s your Minimum Order Quantity?

Any small order quantity is warmly welcomed.

Question 6: What sea port do you ship at?

Any port of China is OK.

Question 7: Can I get spare parts from your factory?

Yes. We provide spare parts according to your machine needs.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches