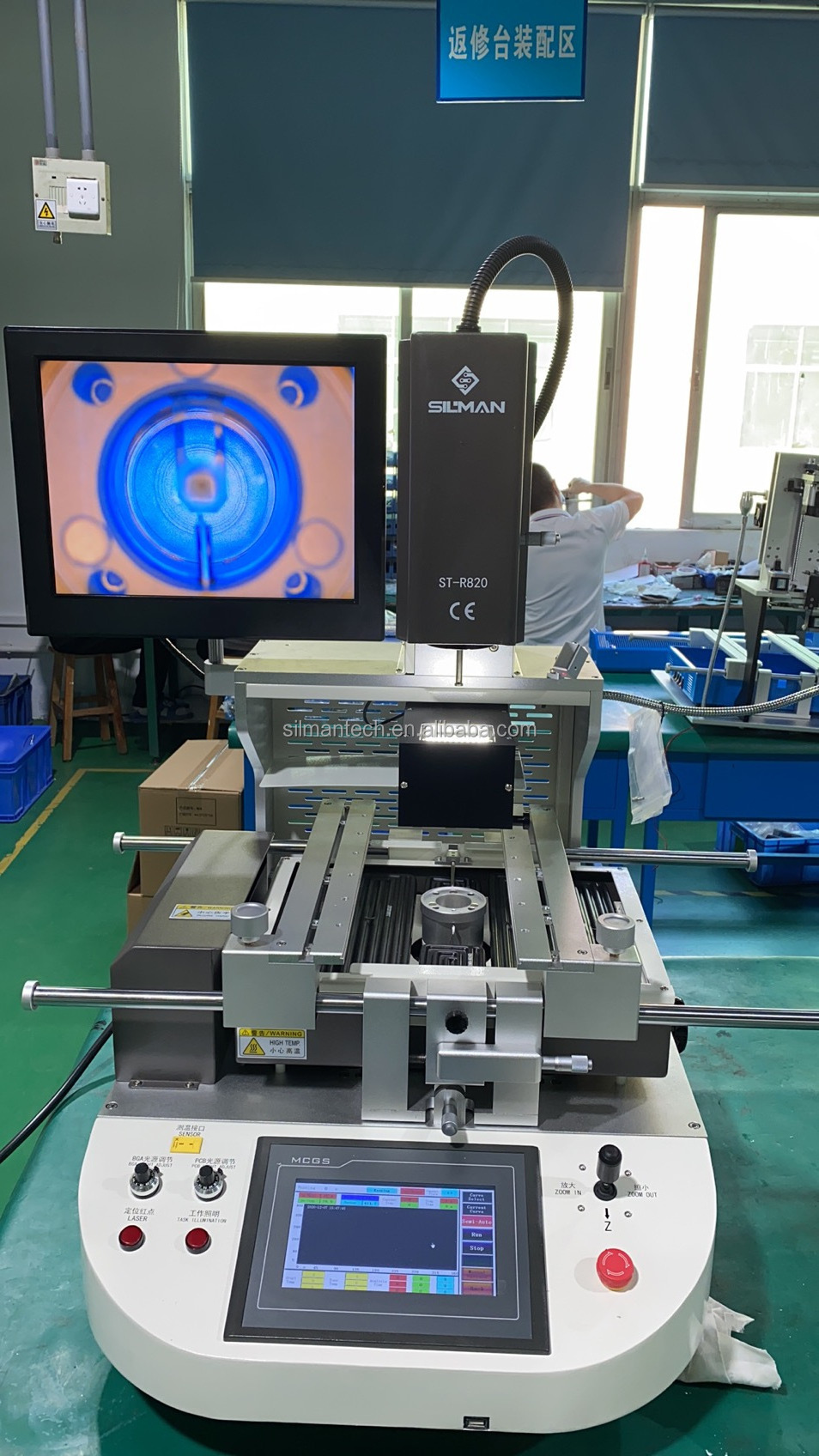

Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions, has automatic

chromatism resolution and brightness adjustment system, amplify to 230 X, mounting accuracy within ±0.01mm.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/220V

-

Current:

-

dependable

-

Rated Capacity:

-

5300W

-

Rated Duty Cycle:

-

NA

-

Dimensions:

-

L650*W630*H850mm

-

Use:

-

motherboard IC bga repair machine

-

Product Name:

-

BGA Repair machine

-

Top heater:

-

1200W

-

Bottom heater:

-

1200W

-

infrared heater:

-

2700W

-

IR Heating Area:

-

280*380mm

-

Application:

-

TV/computer/laptop/mobile/game consoles repair

-

BGA chip size:

-

Max 80*80mm Min 1*1 mm

-

PCB size:

-

Max450*390mm, Min 10*10mm

-

function:

-

BGA SMD IC CHIPS Motherboard repair rework station

-

Optical system:

-

Japanese original high-definition CCD color imaging system

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Silman

-

Weight (KG):

-

60KG

-

Voltage:

-

110V/220V

-

Current:

-

dependable

-

Rated Capacity:

-

5300W

-

Rated Duty Cycle:

-

NA

-

Dimensions:

-

L650*W630*H850mm

-

Use:

-

motherboard IC bga repair machine

-

Product Name:

-

BGA Repair machine

-

Top heater:

-

1200W

-

Bottom heater:

-

1200W

-

infrared heater:

-

2700W

-

IR Heating Area:

-

280*380mm

-

Application:

-

TV/computer/laptop/mobile/game consoles repair

-

BGA chip size:

-

Max 80*80mm Min 1*1 mm

-

PCB size:

-

Max450*390mm, Min 10*10mm

-

function:

-

BGA SMD IC CHIPS Motherboard repair rework station

-

Optical system:

-

Japanese original high-definition CCD color imaging system

-

Certification:

-

CE

Product Description

ST-R820 low price IR infrared automatic BGA IC CHIP soldering reballing repair rework Station / machine

(1)Application

1. Smart phone /iPhone/iPad repair

2. Notebook/ Laptop /Computer/Mac book /PC repair

3. XBOX 360/PS2/ PS3/PS4 Wii and so on video game consoles repair

4. Other LED/SMD/SMT/IC BGA repair

5. BGA VGA CPU GPU soldering and de-soldering repair

1. Smart phone /iPhone/iPad repair

2. Notebook/ Laptop /Computer/Mac book /PC repair

3. XBOX 360/PS2/ PS3/PS4 Wii and so on video game consoles repair

4. Other LED/SMD/SMT/IC BGA repair

5. BGA VGA CPU GPU soldering and de-soldering repair

6.BGA chips, QFP QFN chip, PC, PLCC PSP PSY rework /repair.

(2) Main Features

♦ 5 working modes

♦ 15’’ HD LCD monitor

♦ 7’’ HD touch screen

♦ CCD color optical alignment system

♦ Laser light for positioning

♦ Infrared preheat tubes + hot air heating areas

♦ HD camera comes in & out automatically by button

♦ Temperature accuracy within ±1℃

♦ Mounting precision within ±0.01mm

♦ Repair success rate: 99% +

♦ 5 working modes

♦ 15’’ HD LCD monitor

♦ 7’’ HD touch screen

♦ CCD color optical alignment system

♦ Laser light for positioning

♦ Infrared preheat tubes + hot air heating areas

♦ HD camera comes in & out automatically by button

♦ Temperature accuracy within ±1℃

♦ Mounting precision within ±0.01mm

♦ Repair success rate: 99% +

Specification

ST-R820 automatic infrared BGA repair machine

* 3 independent control heaters

① Top and bottom heaters are hot-air heating while the third IR heater is infrared heating. The top and bottom heaters can heat

PCB from upper and bottom at the same time. With a temperature accuracy within ±3℃,there are multi segments which can be set at

the same time; IR preheating area is adjustable according to demand and heat PCB evenly.

② It can heat PCB board and BGA chips at the same time. The third IR heater can preheat the PCB board from bottom to prevent PCB

from deformation during repair process. The top and bottom heaters can work independently;

③ Choose high accurate K type close-loop thermocouple, and PID parameters automatic adjustment system;it can show seven

temperature curves and the millions of groups data can be saved through U storage device with instant curve analysis function of

BGA temperature at any time; The sensor is for precise temperature testing.

* Precise optical alignment system

Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions, has automatic

chromatism resolution and brightness adjustment system, amplify to 230 X, mounting accuracy within ±0.01mm.

* Multi-function operation system

① Adopt high definition human-machine interface, available for setting “set up” and “operate” to avoid error settings, The top

heater device and mounting head 2 in 1 design, with automatic identify BGA chips and mounting height, it is of automatic soldering

and des-soldering function.it can set 6 segments rising temperature and 6 segments of activity temperature, and can save N groups

temperature profiles. Adopted all kinds of BGA nozzles, with 360° rotation, easy for installation and replacement, customized is

available;

②V-groove PCB support, with rapid, convenient and accurate positioning, can fit for all kinds of PCB board; Flexible and removable

universal fixture has protective effects and no damage to the PCB board, suitable for all kinds of sizes of BGA repair.

* Superior safety functions

With CE certification; after des-soldering and soldering, there is alarming. when temperature goes out of control;the circuit will

automatically power off, it is of double over-temperature protection function. Temperature parameter has a password to avoid from

arbitrary changes, with superior safety protection functions, can protect PCB board components and the machine from damage at any

abnormal situation

① Top and bottom heaters are hot-air heating while the third IR heater is infrared heating. The top and bottom heaters can heat

PCB from upper and bottom at the same time. With a temperature accuracy within ±3℃,there are multi segments which can be set at

the same time; IR preheating area is adjustable according to demand and heat PCB evenly.

② It can heat PCB board and BGA chips at the same time. The third IR heater can preheat the PCB board from bottom to prevent PCB

from deformation during repair process. The top and bottom heaters can work independently;

③ Choose high accurate K type close-loop thermocouple, and PID parameters automatic adjustment system;it can show seven

temperature curves and the millions of groups data can be saved through U storage device with instant curve analysis function of

BGA temperature at any time; The sensor is for precise temperature testing.

* Precise optical alignment system

Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions, has automatic

chromatism resolution and brightness adjustment system, amplify to 230 X, mounting accuracy within ±0.01mm.

* Multi-function operation system

① Adopt high definition human-machine interface, available for setting “set up” and “operate” to avoid error settings, The top

heater device and mounting head 2 in 1 design, with automatic identify BGA chips and mounting height, it is of automatic soldering

and des-soldering function.it can set 6 segments rising temperature and 6 segments of activity temperature, and can save N groups

temperature profiles. Adopted all kinds of BGA nozzles, with 360° rotation, easy for installation and replacement, customized is

available;

②V-groove PCB support, with rapid, convenient and accurate positioning, can fit for all kinds of PCB board; Flexible and removable

universal fixture has protective effects and no damage to the PCB board, suitable for all kinds of sizes of BGA repair.

* Superior safety functions

With CE certification; after des-soldering and soldering, there is alarming. when temperature goes out of control;the circuit will

automatically power off, it is of double over-temperature protection function. Temperature parameter has a password to avoid from

arbitrary changes, with superior safety protection functions, can protect PCB board components and the machine from damage at any

abnormal situation

|

Product Name

|

Full Automatic BGA Rework Station

|

|

Model #

|

ST-R820

|

|

Overall Power

|

5300W

|

|

Top heater

|

1200W

|

|

Bottom heater

|

1200W

|

|

IR heater

|

2700W

|

|

IR Heating Area

|

280*380mm

|

|

Voltage

|

AC220V±10% 50/60Hz

|

|

Motion Direction

|

Z Axis

|

|

Position System

|

V-groove, PCB support

|

|

Temperature control

|

K-type Closed Loop thermocouple with accuracy within ±3 ℃

|

|

temperature precision

|

±3 degree

|

|

PCB size

|

Max 415*370 mm Min 65*65 mm

|

|

Electrical materials

|

Servo Drive( Panasonic)+Touch screen( Taiwan)+Panasonic PLC+Heating plate(Germany)

|

|

Camera magnification

|

5X~50X

|

|

Optical system

|

Japanese original high-definition CCD color imaging system, Joystick control

|

|

BGA chip

|

Max 80*80mm Min 2*2 mm

|

|

Touch screen

|

10 inch , Resolution 640*480, Panel Visa touch screen, external USB interface

|

|

External temperature sensor

|

1 pc

|

|

Working Mode

|

Power drive(Optional gas drive + nitrogen)

|

|

Placement Accuracy

|

±0.02mm

|

|

Dimension

|

L680*W630*H900 mm (LCD stand not included)

|

|

Net weight

|

79KG

|

|

Certifications

|

CE and Patent certificate

|

|

Packing

|

L780*W800*H1090mm

|

|

Gross Weight

|

105KG

|

Our Advantages

1.High Resolution CCD Camera with optical lens

2.High Sensitive Touch Screen

10 inch , Resolution 640*480, Panel Visa touch screen, external USB interface.

2 modes can be chose: manual and auto.

3.Strong Plate + Flexible universal jigs(6pcs)

6 pcs will be equipped

.

4.Large IR Heating Zone (2700W)

3 independent control heaters

Packing & Delivery

Details for delivering

1,Standard export wooden package for bga rework station:83*70*87cm,105KG

2,Delivery in 3 working days after payment;

3,Shipping by TNT, UPS ,DHL,FEDEX (IE), Aramex or by air or by sea

4,Loading Port: Shenzhen or Hongkong

Hot Searches