- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

4000*2000mm

-

Cutting Thickness:

-

0-20mm

-

Control Software:

-

bodorpro

-

Place of Origin:

-

Hubei, China

-

Weight (KG):

-

1000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Laser power:

-

4KW 8KW 12KW 20KW

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Laser source:

-

Raycus IPG

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Laser head:

-

Switzerland Raytools

-

Power supply:

-

380V/50HZ

-

Control system:

-

Cypcut Control System

-

Positioning Accuracy:

-

0.03mm

-

After Warranty Service:

-

Online support

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

140m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

4000*2000mm

-

Cutting Thickness:

-

0-20mm

-

Control Software:

-

bodorpro

-

Place of Origin:

-

Hubei, China

-

Weight (KG):

-

1000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Laser power:

-

4KW 8KW 12KW 20KW

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Laser source:

-

Raycus IPG

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Laser head:

-

Switzerland Raytools

-

Power supply:

-

380V/50HZ

-

Control system:

-

Cypcut Control System

-

Positioning Accuracy:

-

0.03mm

-

After Warranty Service:

-

Online support

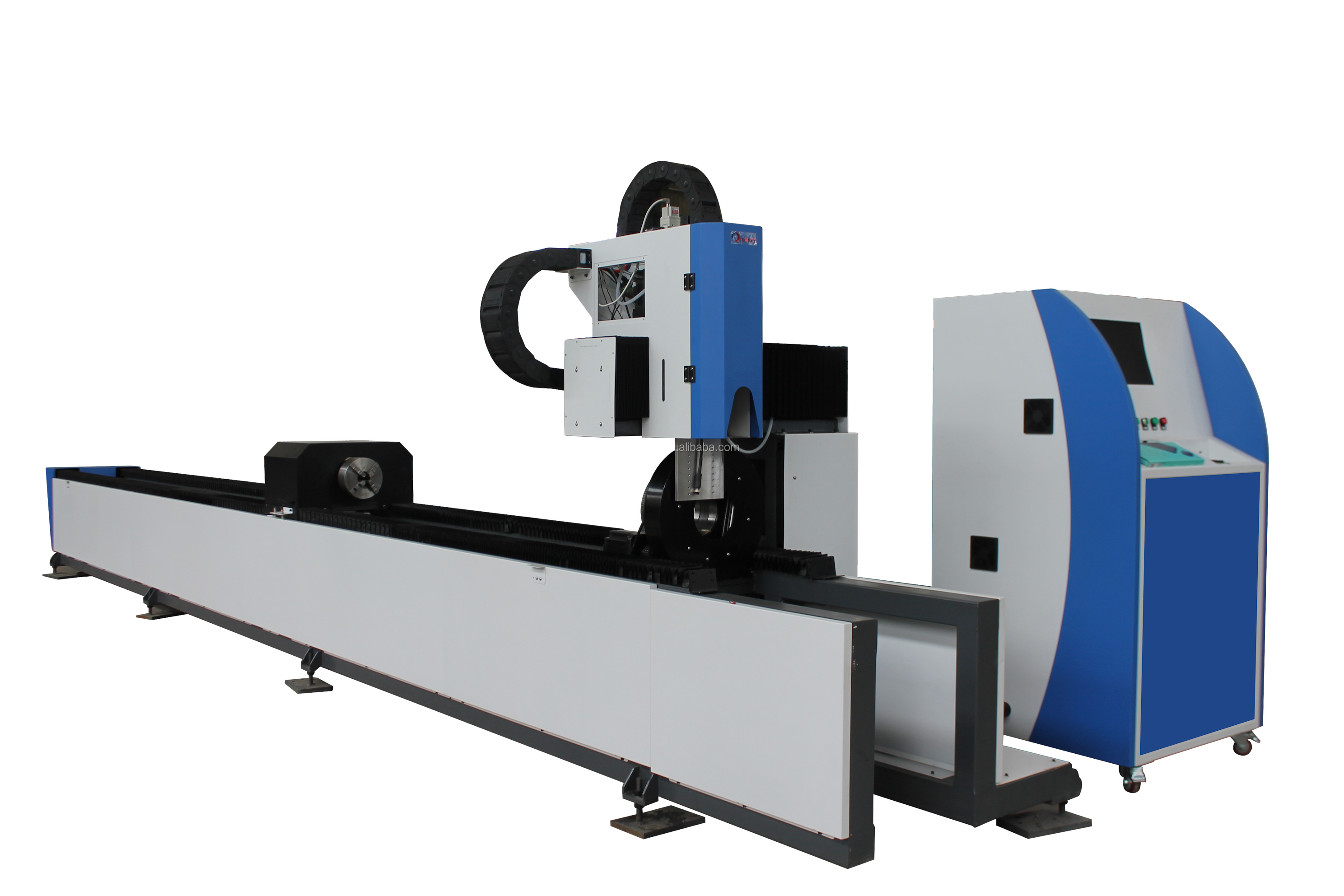

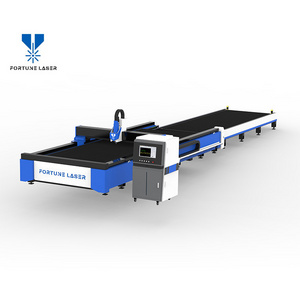

Fiber laser cutting machine 3000watt 4000watt 6000watt CNC lathe cutting device with safety enclosure stainless steel laser cut

Fiber laser is a new type of laser in the world, it has large cooling area, high laser ray quality and small size. Compared with huge size gas laser and YAG laser, fiber has strategically advantage.

Fiber laser has been an important candidate in high precision machinery, laser radar, space technology and laser medical.

Applicable materials :

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applications:

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Characteristic of fiber laser

Ø High electro-optical conversion efficiency, small power fiber laser use air cooling instead of water chiller, can save energy and production cost to improve productivity

Ø Fiber laser needs energy only, no extra gas from laser, has the lowest operating and maintaining cost

Ø Fiber laser using semiconductor modular and redundant design, no optical lens in resonator, no start time, no adjustment, no maintenance, high stability, reduce consume parts cost and maintaining time

Ø F iber laser wave-length is 1060nm, 1/10 of CO2 laser wave-length, high quality output laser ray, high power density, easy to absorb by metal, great cutting and welding ability

Ø L aser path is transmitted by fiber, no optical lens, simple laser path, stable structure, outside optical path is maintenance-free

Ø P rotection lens is built in cutting head, minimum consumption for reflective lens and focus lens

Ø L aser is transmitted by fiber, simplified mechanical structure design, easy to integrate with robot or multi-dimensional table

Ø W hen equipped with shutter, one laser can work with multiple machine, fiber can separate laser to multiple ray to work on multiple machine. Easy to upgrade and expand function.

Ø S mall in size, light in weight, mobile working position, minimum space requirement

Questt fiber laser cutting machine is equipped with world’s top IPG laser, it is stable, product quality is guaranteed.

Equipped with USA imported capacitor non-contact tracking system, able to adjust focal length automatically, guaranty the best cutting quality, prevent material scrapping caused by changing of focal length when metal is not flat . Due to non-contact sensing device, when controlled by system, able to achieve stable Z axis floating function, eliminate negative effects caused by non-flat material

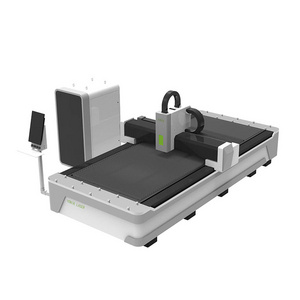

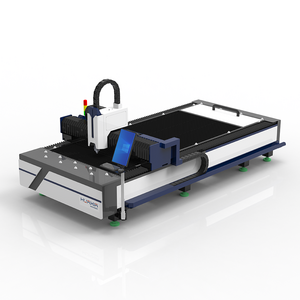

Machine

With moveable gantry structure, beam and body built as one, high precision, durable and stable operation. With automatically exchanging work platform, able to do cutting and material feeding at the same time.

Machine base: with frame structure made from high quality steel plate and pipe, welded by professional military equipment, secondary aging treatment, large scale milling machine processing, those design and processing technology guaranty shaking resistance, high durability and stabilization.

Work Platform: with lift two-table high-speed switching design, can do cutting and loading at the same time, increase productivity. Each platform can load up to 800kg.

Waste emission system: collector is built under machine base, can clean waste and gather small parts

Dust reduction system: work platform has vacuum system, can clean dust and waste

Transmission: Questt laser cutting machine is equipped with import high precision ball screw, linear guide and servo motor drive system, can guaranty cutting precision.

Control system:

Ø Use professional IPC, graphic control panel, easy to use, professional cutting software can design all kinds of graphic, text, support CAD, CorelDraw

Ø Use high quality IPC, high efficient, easy operation, Germany import cutting software

Ø Z axis adjustment program

Ø User friendly control panel with error analysis report

Ø Cutting database can help user to select the best setting

CNC cutting control system is Germany import professional cutting system, based on Windows XP professional, based to work with CNC system perfectly, easy to control and upgrade,.

Advantages of control system:

1. User friendly, easy to learn and operate, CNC program is easy to edit 2. With cutting database, can adjust setting during cutting, to achieve the best performance 3. Can turn off cutting gas when not in use 4. Automatically edge-finding function 5. Cutting head auto-positioning, fast Z axis response

Professional nesting software:

CNC laser cutting machine use auto-program nesting software, programming, nesting, text editing, cut setting can be done automatically, increase material usage.

Advantages of nesting software: Import, micro-connection, cutting order, optimize cutting path and speed

Increase material usage: can do parts gap layout, parts embedded layout, parts reversal symmetry layout, parts rotation layout ;

Prevent over heating: prevent over heating by handle cutting path ;

Angle processing: inside & outside angle processing, can auto-identify; Powerful text processing, can make hollow words; Edge-segment cutting can increase material usage ;

Technical setting: system can set automatically based on material and thickness, include: compensation, cutting power, cutting type, micro-connecting, bridge-connecting, Manage material quantity

Red-dot pointer: Fiber laser cutting machine is equipped with red dot pointer, can help oerator to adjust position of cutting head

Cooling:

Cooling system include stainless steel water tank, heat exchanger, filter, magnetic pump, compressor(imported), water temperature protection and water flow protection.

Technical parameter:

|

Laser type |

Fiber |

|

Laser wave-length |

1070 nm |

|

Output power |

4000 W |

|

Geometric positioning accuracy |

≤±0.05mm |

|

Re-orientation accruacy |

≤±0.0mm |

|

Max load |

16 00KG |

|

Max position speed |

100m/min |

|

X axis travel |

4000mm |

|

Y axis travel |

2000mm |

|

Z axis travel |

1 2 0mm |