- Product Details

- {{item.text}}

Quick Details

-

Packing:

-

Standard Packing

-

Certification:

-

ISO9001

-

Customized:

-

yes

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

YR

-

Packing:

-

Standard Packing

-

Certification:

-

ISO9001

-

Customized:

-

yes

|

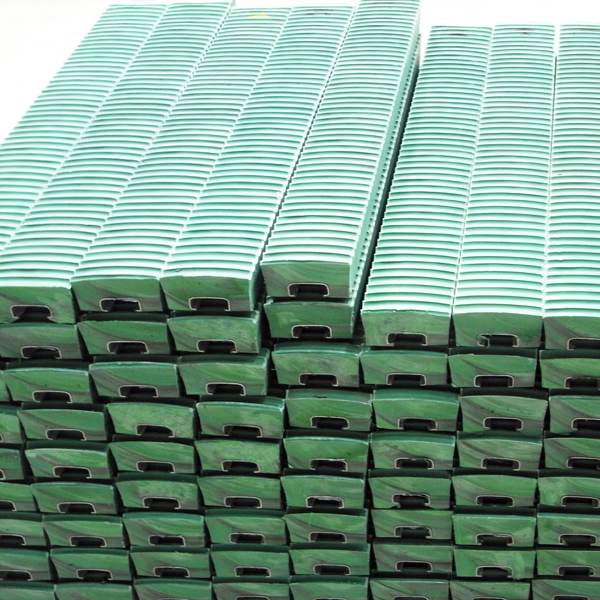

Friction Liner

|

|

|

|

|

||||

From the import of raw materials to the processing of products, we strictly control the product quality of each process, and are committed to providing users with more cost-effective high-performance products.

WK868 friction liner for multi-rope friction elevator, the product performance is stable, and the friction coefficient is greater than 0.28 under any working condition, which fully meets the requirements of use.

The Action of the Friction Liner

Friction lifting, as the name suggests, is to lift heavy objects by friction, in terms of its working principle, and winding lifting is significantly different; The wire rope is not wound on the drum, but on the friction wheel, hanging a lifting container at each end, with the help of friction between the liner installed on the friction wheel and the wire rope to drive the wire rope, so that the lifting container moves up and down, so as to complete the task of lifting or lowering heavy objects. The friction elevator is the key equipment of large mine mining, and the liner is the key component of the friction elevator, which is mainly used for power transmission between the friction wheel and the wire rope.

The friction liner, steel wire rope and grease form a dual friction pair, and the performance of the liner directly affects the lifting ability, work efficiency and safety of the hoist.

|

EFFECT

|

|

|

|

|

||||

|

1、Provide friction

|

|

|

|

|

||||

|

2、Protective wire rope

|

|

|

|

|

||||

|

Performance and parameters

|

|

|

|

|

||||

Use and maintenance

Remove the old liner.

Ways to remove the old liner:

Option 1:

Remove the mounting gate baffle and cut off the bottom of the rope groove using a pistol drill. Use a flat crowbar and other tools to pry the liner on both sides towards the middle, and remove the first piece several times.

Use a flat cone to pry the joints of the two gaskets and remove them in the opposite direction of the wedge.

Option 2:

a: Use a special cutting knife to destructively turn the liner rope groove so that the bottom of the liner rope groove is completely turned through. Pay attention to the amount of feed to prevent turning to the drum wall.

b: Use a flat crowbar to exert force from the left and right directions of the liner. The liner can be easily removed.

Note: Due to the simple operation of scheme 2, the installation intensity is greatly reduced and the installation time is saved. Therefore, coal mines under current conditions use such methods.

After the waste liner is removed, clean the rust and other attachments on the surface of the friction wheel.

Put one half of the liner in first, then the other half in front, and hammer it tight.

Space between blocks allowed, depending on tolerance requirements. The gasket ring is finally connected together by a connector, which has two forms, one is a whole connector, and the other is a multi-piece assembly connector.

A: When installing the whole connector, first fill the gap between the lining blocks with the provided filler blocks and small plates, then put in the two sides of the part, and finally hammer the middle part into place.

B: When installing multi-piece assembly fittings, the gap between the lining blocks must be plugged with filling blocks and small plates, and then gently hammer into. Insert the short wedge (1) in the direction of the arrow, and do the same with the filling blocks (2) and (3). Finally fill the remaining space with the end filler block (4).

5. If the operation is balanced and the indicators are normal, the rope groove can not be turned, otherwise the rope groove can be turned.

6. Please pay attention when the following problems occur

a. The liner is uneven

The padding width is wider than the groove, such as a small amount can be ground on the grinding wheel, such as a large amount on the machine tool processing.

b, the liner into the slot is too loose, you can add the required thickness of steel plate in the liner face.

c, the surface of the liner sticky oil, please use alcohol or acetone clean.

Hot Searches