- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Name:

-

price of soap making machine

-

Usage:

-

Hotel, household, travel soap

-

Material:

-

soap noodle (soap grains), pigment, and fragrance

-

Type:

-

automatic

-

Capacity:

-

500-4500kg/h

-

Heating method:

-

Steamer Heating

-

Function:

-

making soap

-

Advantage:

-

Energy saving and easy control

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kinetic

-

Machine Type:

-

SOAP MAKING MACHINE, Soap Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Name:

-

price of soap making machine

-

Usage:

-

Hotel, household, travel soap

-

Material:

-

soap noodle (soap grains), pigment, and fragrance

-

Type:

-

automatic

-

Capacity:

-

500-4500kg/h

-

Heating method:

-

Steamer Heating

-

Function:

-

making soap

-

Advantage:

-

Energy saving and easy control

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

Product Description

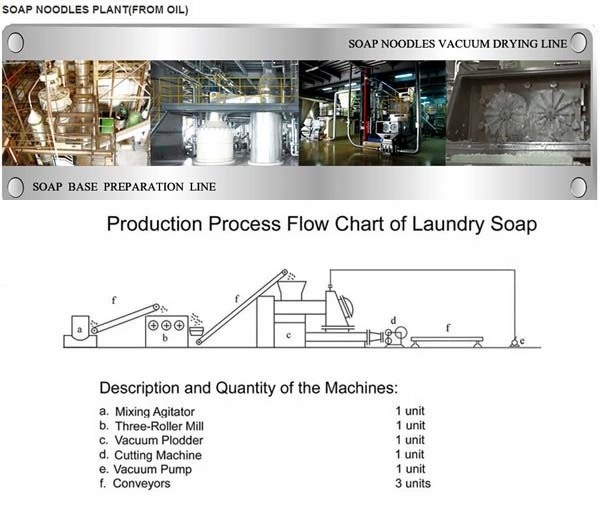

What's the sections of soap processing line ?

1.Trio muller, it is using for rubbing soap material

2.Semi-finished product conveyor, it is using for convey soap pieces

3.Double-screw vacuum plodder, it is using for vacuum ploddering

4.Printing-cutting machine, it is using for cutting and printing

5. Products convey, it is using for Convey products

1.Trio muller, it is using for rubbing soap material

2.Semi-finished product conveyor, it is using for convey soap pieces

3.Double-screw vacuum plodder, it is using for vacuum ploddering

4.Printing-cutting machine, it is using for cutting and printing

5. Products convey, it is using for Convey products

Features of Soap Making Machine:

1. The finishing lines of Series for toilet and translucent soap bring together all components that are most reliable, most

durable, supplied by the most famous vendors in the world.

2. The mechanical design is tend to be simplified, more robust, low energy consumption, low off-stream rate, easy to be maintained

,more people-oriented and with good view both outside and inside of the machines.

1. The finishing lines of Series for toilet and translucent soap bring together all components that are most reliable, most

durable, supplied by the most famous vendors in the world.

2. The mechanical design is tend to be simplified, more robust, low energy consumption, low off-stream rate, easy to be maintained

,more people-oriented and with good view both outside and inside of the machines.

Details Images

Product Flow

Main Production Process:

Saponification--> Vacuum drying --> Soap noodle --> Grinding --> Vacuum extruding --> Cutting. Material and Consuming for

producing soap: Oil or fat of plant or animal (palm oil, coconut oil, tallow oil, etc.), caustic soda (NaOH), sodium-chloride

(NaCl), sodium silicate, fragrance, pigment, etc.

Saponification--> Vacuum drying --> Soap noodle --> Grinding --> Vacuum extruding --> Cutting. Material and Consuming for

producing soap: Oil or fat of plant or animal (palm oil, coconut oil, tallow oil, etc.), caustic soda (NaOH), sodium-chloride

(NaCl), sodium silicate, fragrance, pigment, etc.

Specification

|

Description

|

Specification(mm)

|

Power

|

Frequency

|

Voltage

|

Function

|

|

Trio miller

|

1350*1670*1050

|

7.5kw

|

50Hz

|

380v

|

rubbing soap material

|

|

Semi-finished product conveyor

|

4500*730*1650

|

2.2kw

|

50Hz

|

380v

|

convey soap pieces

|

|

Double-screw vacuum plodde

|

3750*900*2100

|

24.5kw

|

50Hz

|

380v

|

vacuum ploddering

|

|

Vacuum pump

|

--

|

1.5kw

|

50Hz

|

380v

|

vacuum bubble pumping

|

|

Printing-cutting machine

|

800*300*1000

|

3kw

|

50Hz

|

380v

|

cutting and printing

|

|

Products conveyor

|

3000*500*1000

|

0.75kw

|

50Hz

|

380v

|

Convey products

|

|

Stripping machine heater

|

--

|

2.5kw

|

50Hz

|

380v

|

pre –heating ram head

|

Application

Blending reacting boiler is mainly suitable for preparation of liquid detergents (such as cleanser essence,shampoo,shower gel and

liquid soap etc.). Integrating blending ,dispersing ,heating and cooling etc. functions.The reacting machine is and ideal device

for liquid preparation in various factories.

liquid soap etc.). Integrating blending ,dispersing ,heating and cooling etc. functions.The reacting machine is and ideal device

for liquid preparation in various factories.

Customer Soap Project Share

It is a turn-key project. The professional team provide you all machines and accessories, the whole process of production, formula, layout design, machines installation, products trial etc. all solution according to your requirements.

Packing & Delivery

Hot Searches