- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hebei Zetian

-

Model Number:

-

2131-2T

-

Type:

-

powder/flake/liquid

-

Product name:

-

Phenolic resin for bonded abrasive

-

Keywords:

-

Phenolic resin

-

Material:

-

Phenol

-

Color:

-

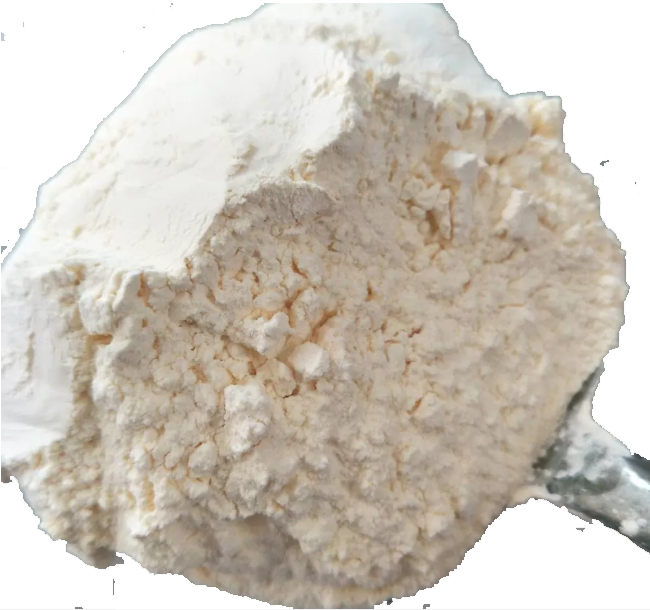

White/light yellow powder

-

Application/ Characteristic:

-

General-purpose ultra-thin sheet of resin (green, black)

-

Packing:

-

25kg/bag or 500kg/bag

-

Shelf life:

-

4-6 month

-

granular:

-

99% under 200mesh

-

pellet flow:

-

30-50

-

free phenol:

-

1.5-2.5

Quick Details

-

CAS No.:

-

9003-35-4

-

Other Names:

-

Bakelite powder

-

MF:

-

[C8H8O2]n

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hebei Zetian

-

Model Number:

-

2131-2T

-

Type:

-

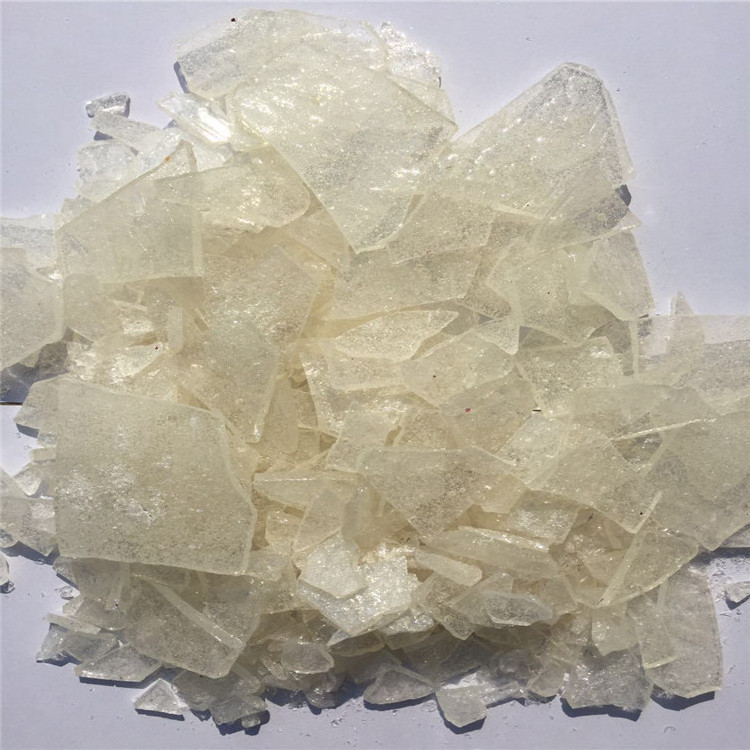

powder/flake/liquid

-

Product name:

-

Phenolic resin for bonded abrasive

-

Keywords:

-

Phenolic resin

-

Material:

-

Phenol

-

Color:

-

White/light yellow powder

-

Application/ Characteristic:

-

General-purpose ultra-thin sheet of resin (green, black)

-

Packing:

-

25kg/bag or 500kg/bag

-

Shelf life:

-

4-6 month

-

granular:

-

99% under 200mesh

-

pellet flow:

-

30-50

-

free phenol:

-

1.5-2.5

There are the powder and liquid resin for bonded abrasives production to meet the demand of different domain. This series is adopted advanced production equipment and processing. With strict formula design, effective molecular weight and distributing control method, it makes the distributing of resin molecular reach an extremely ideal status. The powder resin is characterized in strong viscosity, mechanical strength, abrasion resistance, heat resistance and wet grinding stability. As the excellent wetter, the liquid resin has a good wetting function and well-distributed miscibility. It makes the liquid resin with good humidity by the special processing. There is no caking under the high humid environment and with high intensity and good grindability, which is the excellent product for grinding wheel.

Technical data for powder resin :

|

Grade |

Appearance |

Free phenol (%) |

pellet flow /125 ℃ (mm) |

cure /150 ℃ (s) |

Granularity |

Application/ Characteristic |

|

2123-1 |

White/light yellow powder |

≤2.5 |

30-45 |

50-70 |

99% under 200 mesh |

General-purpose ultra-thin sheet of resin (green, black) |

|

2123-1T |

≤2.5 |

20-30 |

50-70 |

High-strength ultra-thin sheet of resin (black) |

||

|

2123-2T |

≤2.5 |

25-35 |

60-80 |

High-strength grinding, cutting wheel (modified) |

||

|

2123-3 |

≤2.5 |

30-40 |

65-90 |

High-strength cutting wheel (durable) |

||

|

2123-4 |

≤2.5 |

30-40 |

60-80 |

Grinding wheel dedicated (durable) |

||

|

2123-4M |

≤2.5 |

25-35 |

60-80 |

Special grinding wheel (sharp type) |

||

|

2123-5 |

≤2.5 |

45-55 |

70-90 |

Grinding wheel fine material dedicated |

||

|

2123W-1 |

White/light yellow flakes |

3-5 |

40-80 |

50-90 |

-- |

Resin sheet for mesh cloth |

Technical data of liquid resin for grinding wheel :

|

Grade |

Viscosity /25 ℃ (cp) |

SRY(%) |

Free phenol (%) |

Application/ Characteristic |

|

2127 (T) |

600-1000 |

70-76 |

14-18 |

Universal impregnating component, special for mesh |

|

2127-1 |

650-2000 |

72-80 |

10-14 |

Universal impregnating component |

|

2127-2 |

600-2000 |

72-76 |

10-15 |

Good anti-attenuation |

|

2127-3 |

600-1200 |

74-78 |

16-18 |

Universal impregnating component, good wet ability, water resistance |

Flake/Powder: 20 kg /bag, Resin should be stored in a cool, dry and well ventilated place. The storage life is 4-6 months below 20 ℃ . Its color will become dark with the storage time, which will do no influence on the resin grade. Liquid: 200Kg/drum. Resin should be stored in a cool and well ventilated slide gates below 20 ℃ , far away form light. The common storage time: 2 months in winter and 1 month in summer(Advise: stored below 10 ℃ ).