- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

900 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RAYMAX/Beilin

-

Weight (KG):

-

2870

-

Motor Power (kw):

-

5.5 kw

-

Certification:

-

ce

-

After-sales Service Provided:

-

Free spare parts

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

United States

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

1600 mm

-

Slider Stroke (mm):

-

160 mm

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

900 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RAYMAX/Beilin

-

Weight (KG):

-

2870

-

Motor Power (kw):

-

5.5 kw

-

Certification:

-

ce

-

After-sales Service Provided:

-

Free spare parts

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

United States

Products Description

cnc hydraulic small press brake machine, plate metal bending machine price trade

CNC series Electro hydraulic serve pump controller CNC press brake is of servo main motor which drives 2 way pump to control dual.

Oil cylinder synchronously mechanical (hydraulic)crowning compensation device is equipped

The press brake features energy saving by 50%, oil volume saving by 70% compared with traditional hydraulic press bake

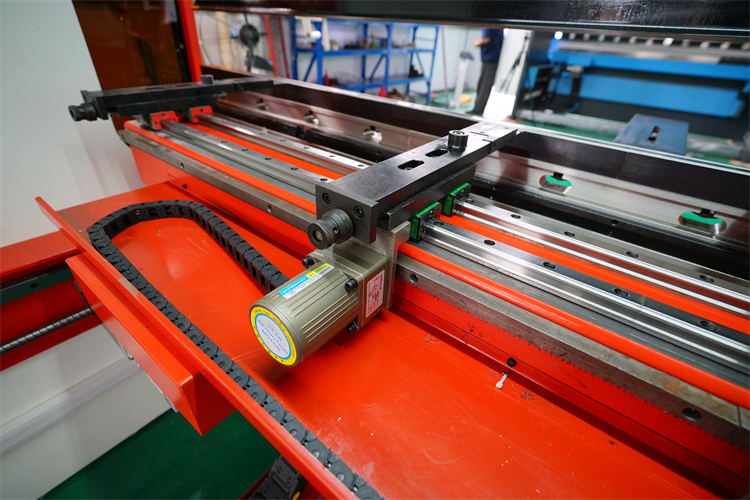

Multi backgauge axes are available steel weld machine frame gets annealing treatment with constant accuracy Netherlandish DELEM DA66T.

|

Product

|

CNC hydraulic press brake

|

|

Backgauge axes

|

3+1Axis /4+1Axis /5+1Axis /6+1Axis/7+1Axis/8+1Axis /10+1Axis

|

|

Optional controller

|

DA53T/DA58T/DA66T/DA69T

|

|

Bending material

|

Carbon steel、Stainless steel、Aluminum、galvanized steel 、Iron and etc.

|

Product Parameters

|

Model

|

column distance(mm)

|

throat depth(mm)

|

opening height (mm)

|

main motor (KW)

|

weight(Ton)

|

|

63t/2500

|

1900

|

250

|

360

|

5.5

|

3.6

|

|

63t/3200

|

2600

|

220

|

360

|

5.5

|

4.2

|

|

80t/2500

|

1900

|

320

|

380

|

7.5

|

4.1

|

|

80t/3200

|

2600

|

320

|

380

|

7.5

|

4.8

|

|

80t/4000

|

3100

|

320

|

380

|

7.5

|

5.3

|

|

100t/2500

|

1900

|

320

|

380

|

7.5

|

5.1

|

|

100t/3200

|

2600

|

320

|

380

|

7.5

|

5.9

|

|

100t/4000

|

3100

|

320

|

380

|

7.5

|

6.8

|

|

125t/3200

|

2600

|

320

|

400

|

7.5

|

6.2

|

|

125t/4000

|

3100

|

320

|

400

|

7.5

|

7.2

|

|

160t/3200

|

2600

|

320

|

450

|

11

|

9.2

|

|

160t/4000

|

3100

|

320

|

450

|

11

|

10.5

|

|

200t/3200

|

2600

|

320

|

450

|

11

|

10.5

|

|

200t/4000

|

3100

|

320

|

450

|

11

|

11.8

|

|

200t/5000

|

4000

|

320

|

450

|

11

|

13

|

|

250t/3200

|

2600

|

350

|

550

|

11

|

15

|

|

250t/4000

|

3100

|

350

|

550

|

18.5

|

18

|

|

300t/4000

|

3100

|

350

|

550

|

22

|

22

|

|

400t/4000

|

3100

|

350

|

550

|

30

|

23

|

|

400t/6000

|

5000

|

350

|

550

|

30

|

29

|

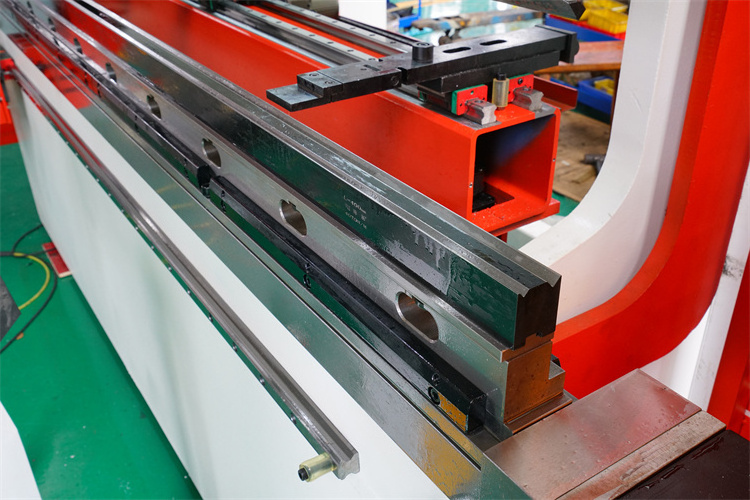

Characteristics

1). This machine adopts hydraulic electric control, sliding block stroke can be adjusted, and have some fixed, semi-automatic, automatic movements such as norm, using dynamic specification can easily test and adjustment

2). lift bending machine design, double oil cylinder work at the same time, balance, convenient operation, safety

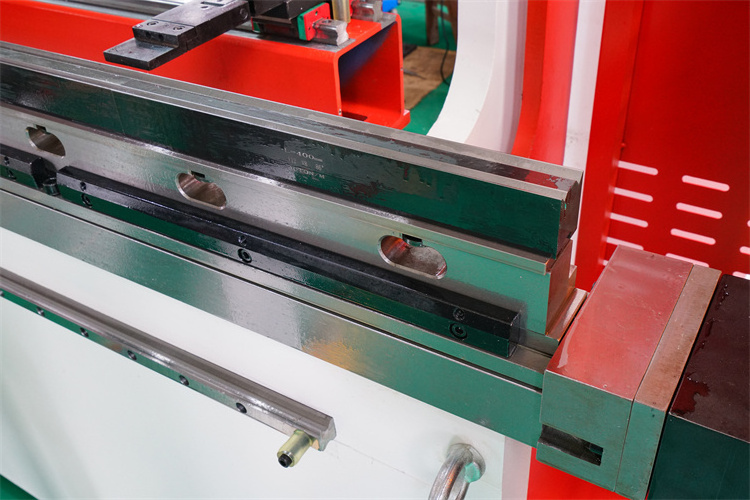

3). The dead point have confirmed when rolling function, ensure that the workpiece precision

4). Under the condition of the relevant national standards, bending Angle precision of plus or minus 45 '. (refer to standard JB/T22572-1999)

5). A slow decline control function, the operator can better control the workpiece

Hydraulic system

1). Hydraulic system can realize the slider falling fast, slow down, bending work speed, quick return of slider stop in process of upward and downward movements

2). The axial plunger pump, oil pump adopt can withstand high pressure, low noise

3). Choose import company seal, sealed performance is good, reliable operation, long service life

4). The machine can work continuously under rated load, the hydraulic system without leakage and sustained stability,high precision.

Application

The folded sheet metal bending machine has high productivity and high working accuracy, using different shapes of up and down mould, can be bent into various shapes artifacts, slider stroke at a time can be to a bending forming of sheet metal, after a lot of bending can be achieved relatively complex shape workpiece, when equipped with the corresponding equipment, can also make a punch

Features

1.Standard two axis control (X.Y)

2. Mechanical torque synchronization(torsion bar)

3.The whole machine is in sheet plate welded structure, with internal stress eliminated by vibration aging technology, ensure machine high strength and good rigidity

4.Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of slider, and installed with digital display device, easy and quick for operator

5.Quick clamping is equipped,it is convenient for operator to install and get offer punch

Hot Searches