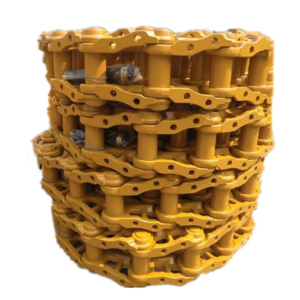

Track pin sleeve is an important connection of the combination track, it not only withstand the contact pressure stress

transmitted by the drive wheel teeth, but also to withstand severe abrasive wear, because the pin sleeve always works under the

condition of multiple shocks of small energy. According to the working characteristics of the pin sleeve, the material can be 20Mn

and 25MnTiBR heat treatment carburizing, one or two quenching at low temperature tempering, hardness is 58-62HRC, such as the use

of 60dt,T8 or T10 and other materials, after quenching and low temperature tempering life can be improved a lot!

- Product Details

- {{item.text}}

Quick Details

-

Part name:

-

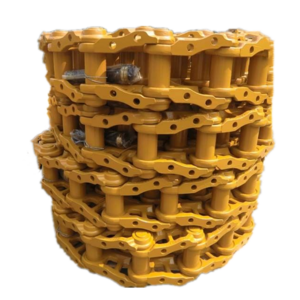

Track Chain

-

Product name:

-

D4H D5

-

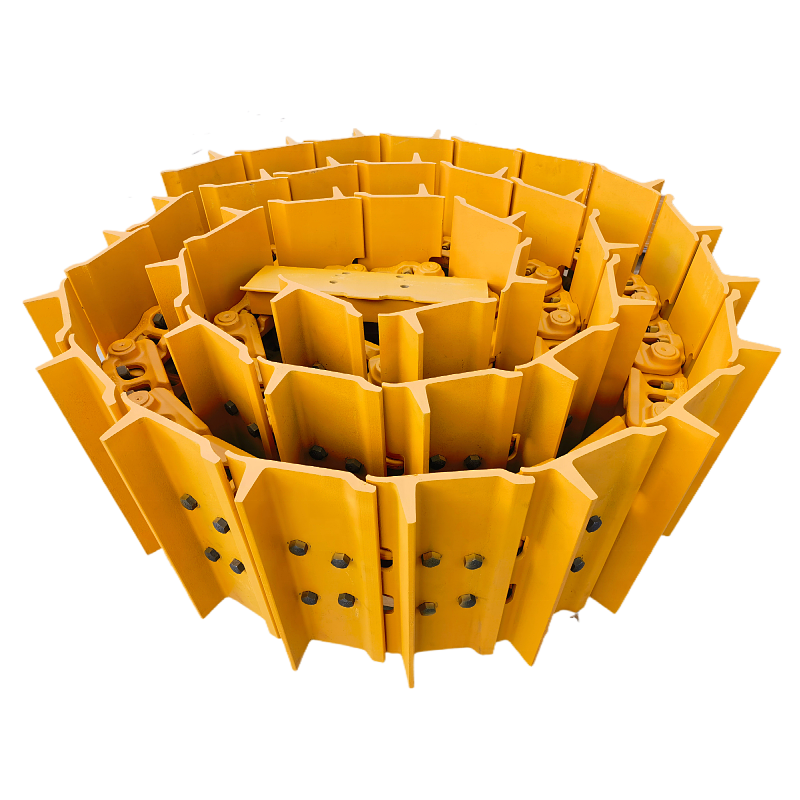

Color:

-

Yellow

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

QLITR

-

Application:

-

Bulldozer

-

Part name:

-

Track Chain

-

Product name:

-

D4H D5

-

Color:

-

Yellow

Product Description

产品介绍:履带板总成

|

Product Name

|

D6R

|

Style

|

|

|

Brand

|

Aitui

|

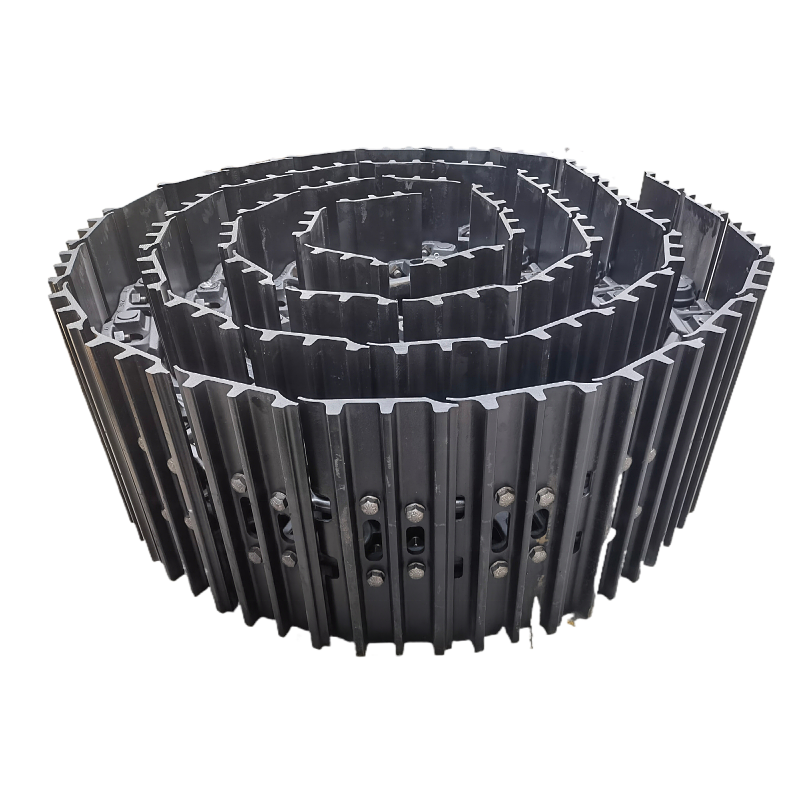

Colour

|

black

|

|

Hardness

|

HRC 50-56

|

Place of Product

|

Fujian Province,China

|

|

Material

|

35MNB

|

Modes of packing

|

wooden support

|

|

Size

|

Sofa: 110*110*80CM

|

After sale service

|

|

Detailed Images

Material Description

Integral track is on the track plate with meshing teeth, directly engaged with the drive wheel, the track plate itself becomes the

support wheel, etc. Integral track is on the track plate with meshing teeth, directly with the rolling track of the drive. The

track plate is connected with a pin shaft, and the pin is floating in the pin hole and has a gap of 0.5-1.5mm. This track is

generally used in large excavators. The advantage of this track is that it is convenient to manufacture and easy to disassemble

and assemble. The disadvantage is that dirt such as sand is easy to enter the pin hole, which speeds up the wear of parts and

affects the service life.

support wheel, etc. Integral track is on the track plate with meshing teeth, directly with the rolling track of the drive. The

track plate is connected with a pin shaft, and the pin is floating in the pin hole and has a gap of 0.5-1.5mm. This track is

generally used in large excavators. The advantage of this track is that it is convenient to manufacture and easy to disassemble

and assemble. The disadvantage is that dirt such as sand is easy to enter the pin hole, which speeds up the wear of parts and

affects the service life.

Material Description

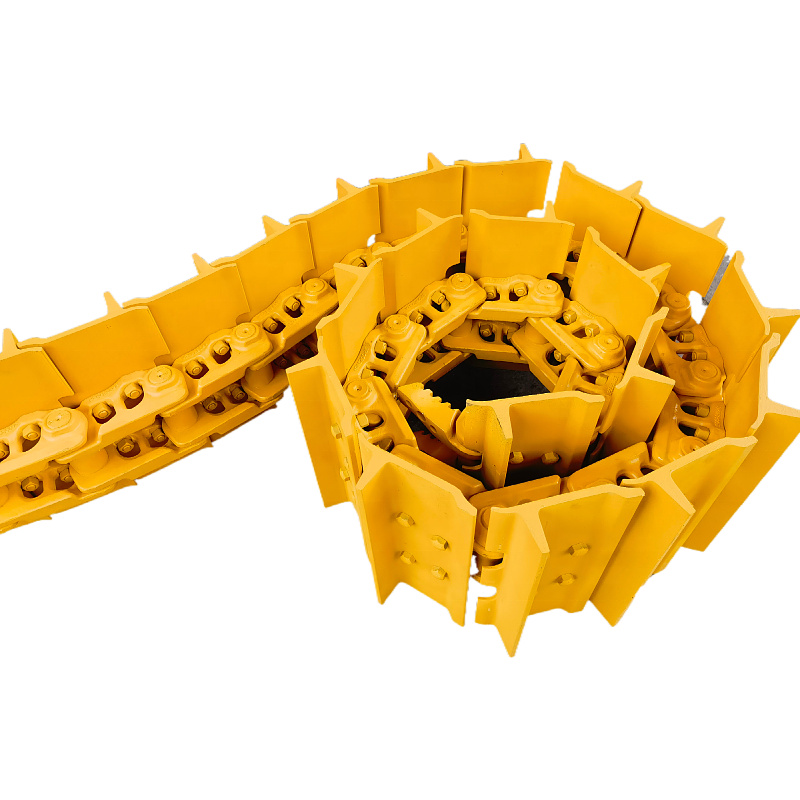

The combined track is composed of a rail link, a track plate, a pin and a bushing. The rail link and track plate are bolted

together. The fit of the track pin and the bushing is 0.5-1.5mm interference tight fit, and the assembly should be carried out on

the press of more than 40t. In order to facilitate installation and disassembly, one of the controls can be converted into a

looser fit.

The advantages of the combined track are: the seal of the pin and the bushing is better, the dirt such as sand is not easy to

enter, because the hardness of the pin and the bushing is higher, the connection is more wear-resistant, so the service life is

also higher; Track pitch is small, good rotation, will not be due to track plate damage, bushing cracking or connection bolt cut

and stop the walking. In addition, the combined track parts have a high degree of universality, and the wearing parts are easy to

purchase, so the maintenance and replacement are convenient and the manufacturing cost is low. The disadvantage is that the

connection bolt is easy to break, and it is difficult to disassemble.

together. The fit of the track pin and the bushing is 0.5-1.5mm interference tight fit, and the assembly should be carried out on

the press of more than 40t. In order to facilitate installation and disassembly, one of the controls can be converted into a

looser fit.

The advantages of the combined track are: the seal of the pin and the bushing is better, the dirt such as sand is not easy to

enter, because the hardness of the pin and the bushing is higher, the connection is more wear-resistant, so the service life is

also higher; Track pitch is small, good rotation, will not be due to track plate damage, bushing cracking or connection bolt cut

and stop the walking. In addition, the combined track parts have a high degree of universality, and the wearing parts are easy to

purchase, so the maintenance and replacement are convenient and the manufacturing cost is low. The disadvantage is that the

connection bolt is easy to break, and it is difficult to disassemble.

Related Products

Packing&Shipping

Company Introduction

Nan an Aitrui Machinery Technology Co., LTD

Specializing in the production of various excavators, bulldozers, drilling machines, pavers, agricultural machinery and other chassis parts series products.

The company mainly has support wheel, sprocket, drive wheel, guide wheel, chain, track assembly, chassis accessories, professional customized company LOGO, provide OEM/ODM services, accumulated rich production experience, for domestic, for foreign, enterprises gradually established a sound sales service network.

Our Services & Strength

FAQ

1. You are a trader or a manufacture?

We are an industry and trade integration business, our factory located on Quanzhou Nanan Distric, and our sales department is in City centre of Xiamen. The distance is 80Kms, 1.5 hours.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or Trade Assurance. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is one 20’ full container and LCL container (less than a container load) can be acceptable.

5. What is your delivery time?

FOB Xiamen or any Chinese port : 20 days . If there are any parts in stock , our delivery time is only 0-7 days.

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

Hot Searches