- Product Details

- {{item.text}}

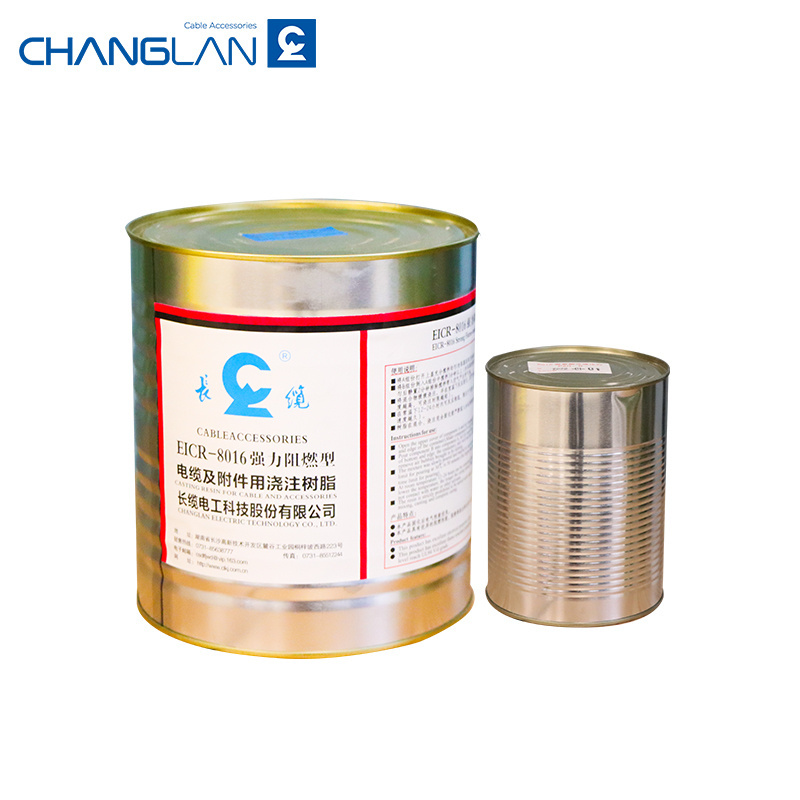

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Changlan

-

Model Number:

-

EICR-8012

-

Type:

-

A & B componets

-

Product name:

-

EICR-8012 Polyurethane Raw Materials

-

Weight:

-

25KG/Set

-

Package:

-

Customized Package

Quick Details

-

CAS No.:

-

MoisturTwo-component Polyurethane Raw Materials

-

Other Names:

-

Moisture Proof Sealing Material

-

MF:

-

Polyurethane

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Changlan

-

Model Number:

-

EICR-8012

-

Type:

-

A & B componets

-

Product name:

-

EICR-8012 Polyurethane Raw Materials

-

Weight:

-

25KG/Set

-

Package:

-

Customized Package

Moisture Proof Sealing Material Waterproof Two-component Polyurethane Raw Materials high voltage cable sealant

ü High solid content.

ü Good bonding property.

ü Resistant to acid, alkali, salt and other chemical corrosion.

ü Great insulation performance .

ü Long-term waterproof and insulation properties.

ü Good fire protection effect .

Product Introduction

Moisture proof sealing material is widely used for moisture proof sealing in distribution control cabinet, RMU, HV/LV switch cabinet, cable branch box, terminal box, pad-mounted transformer, mechanism operation box, assembly control unit, which has low viscosity, good fluidity and easy penetration, resistant to natural freeze-thaw cycle and all kinds harsh environment, while no deformation, no deterioration, no cracking.

With a variety of metal materials, cable sheath material can be closely bonded and not corroded, but also effectively prevent small animals from underground into the cabinet, reduce safety risks; to realize the closed cabinet moisture proof, prevent cable interlayer or channel from moisture, to provide reliable protection for production and operation equipment.

Applications

This product is mainly used for pouring and filling in the terminals and joints of 500KV and under 500KV applications. M oisture-proof sealing of distribution control cabinet, RMU, HV/LV switch cabinet, cable branch box, terminal box, pad-mounted transformer, mechanism operation box, assembly control unit and etc.

Instructions

1. Clean up the dust, oil, impurities, etc. on the working face, and carry out the construction after the surface is dry;

2. To apply material sealing on the big hole, gap in the base surface;

3. Mix material A evenly and pour it into the batching bucket (large), then pour material B into the batching bucket and stir it thoroughly, pay attention to scraping the bottom and wall of the container when stirring;

4. Pouring the well-stirred mixture into bucket (small), and then successively to the need to block the base surface of uniform pouring, fully leveling, vulcanization;

5. the material specification (including A material 0.7 kg, B material 0 .1 kg, A:B= 7 :1)

6. During the operation process and before the product is getting dry, it should be waterproof, anti-pollution, anti-movement, anti-bending, anti-touch, and timely repair if there is any damage;

7. The product operation time is about 25~30min, the full curing time is 1~2h.

Typical properties

|

Place of Origin |

Hunan China |

|

Brand Name |

Changlan or OEM |

|

Breakdown Strength(kv/mm) |

≥ 18 |

|

Volume Resistivity( Ω .CM) |

≥1*10 13 |

|

Dielectric Constant |

≥ 10 |

|

Dielectric Loss Tangent |

≥ 0.2 |

|

Tear Strength(KV/MM) |

≥ 20 |

|

Oxygen Index (%) |

≥ 2 5 |

|

Operation Temperature ( ℃) |

-40~120 |

|

Shelf Life |

2 years |

|

Sample |

Supplied |

Product Specification

|

Model and Specification |

No. 1 |

No. 2 |

No. 3 |

No. 4 |

No. 5 |

|

A Componet Weight(g) |

700±3 |

2632±5 |

7000±20 |

8750±20 |

12900±30 |

|

B Componet Weight(g) |

100±3 |

376±3 |

1000±5 |

1250±5 |

3100±10 |