- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

PUREPATH

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

used oil to diesel machine

-

Function:

-

Diesel Distillation Machine

-

Raw material:

-

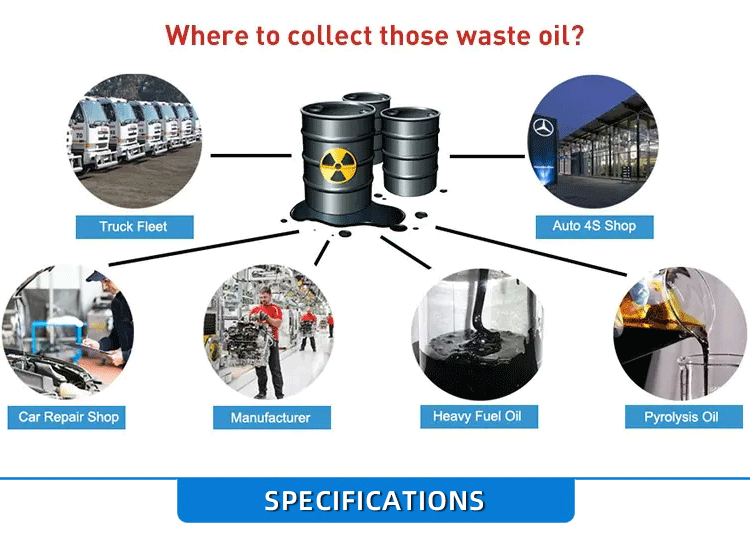

Waste Lube Oil/Pyrolysis oil

-

End product:

-

80-93% Diesel

-

Capacity:

-

5-200TPD

-

Advantages:

-

Fully Continuous

-

Working temperature:

-

30~460 ℃

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE&ISO

Quick Details

-

Applicable Industries:

-

waste oil re-refine, pyrolysis oil distillation, Refinery

-

Marketing Type:

-

New Product 2024

-

Flow:

-

5-200 TPD

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

PUREPATH

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

used oil to diesel machine

-

Function:

-

Diesel Distillation Machine

-

Raw material:

-

Waste Lube Oil/Pyrolysis oil

-

End product:

-

80-93% Diesel

-

Capacity:

-

5-200TPD

-

Advantages:

-

Fully Continuous

-

Working temperature:

-

30~460 ℃

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE&ISO

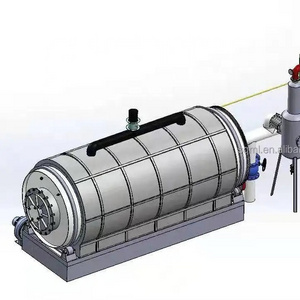

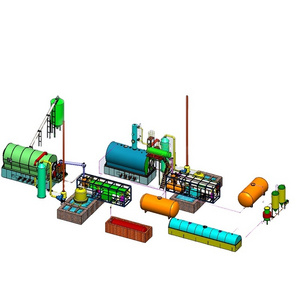

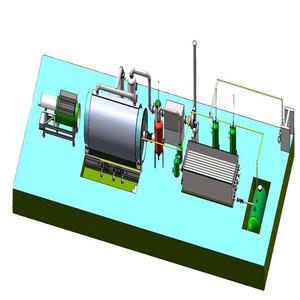

Tire Pyrolysis Oil And Plastic Pyrolysis Oil Recycling Distillation Plant

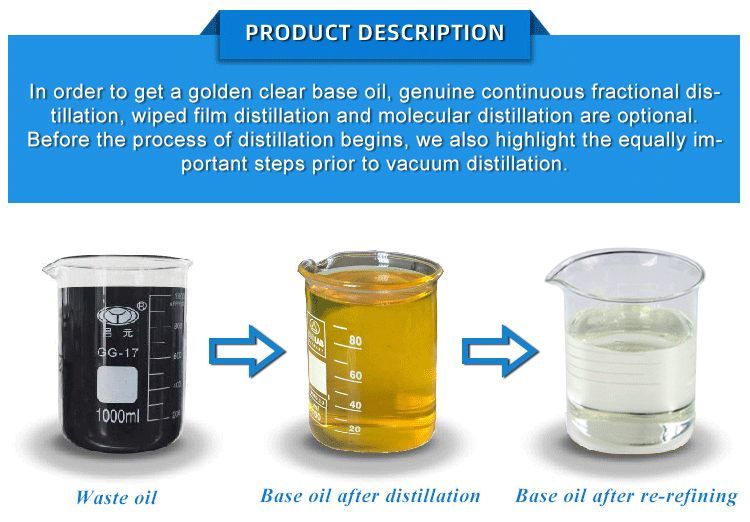

A fractionation distillation and WFE and SPD technologies are optional to guarantee the genuine continuous of PPGT-BP series vacuum oil distillation plant. It adopts PurePath exclusive technology to reduce the pressure drop and keep a sustained and stable high vacuum condition during operation. It largely avoids local overheating to crack the oil molecular and lead to bad performance of end oil product. With PPGT-BP series plant, it's able to obtain SN70~SN500 base oil with good performance in viscosity indexes and flash point, and transparent color,qualified odor etc..

| Model No. | PPGT-BP-1 | PPGT -BP-2 | PPGT -BP-3 | PPGT -BP-4 | PPGT -BP-5 | PPGT -BP-6 | PPGT -BP-7 | PPGT -BP-8 |

| Items. | ||||||||

| Process Capacity MAX. | 2 TPD | 5 TPD | 10 TPD | 15 TPD | 20 TPD | 30 TPD | 50 TPD | 100 TPD |

| Heating Power | 17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL | |||||||

| Power Consumption | 25KWH PER TONS OF WASTE OIL | |||||||

| Vacuum Degree | Less than-0.05KPa | |||||||

| Heating Method | Fuel Oil/Natural Gas/LPG/Electricity | |||||||

| Heating Temp. | 30-350℃ | |||||||

| Voltage | 220/380/415V 50/60HZ | |||||||

| Noise | ≤60dB | |||||||

| PROPERTY | METHOD | RESULT UNITS | |||||

| Type | LBO | HBO | |||||

| Appearance | Visual Inspection | Bright&Clear | Bright&Clear | ||||

| Color scale | ASTM D1500 | ≤1 | ≤1.5 | ||||

| Water Content | ASTM D1744 | Trace (% wt) | Trace (% wt) | ||||

| Kinematic Viscosity at 40℃ | ASTM D445-15a | 32.170 mm2/s | 67.420 mm2/s | ||||

| Viscosity Index | ASTM D2270-10 | 117 | 122 | ||||

| Total Sulfur Content | ASTM D4294-16e1 | 0.0071 %(m/m) | 0.0093 %(m/m) | ||||

| Density at 15 ℃ | ASTM D4052-18 | 0.898 kg/m3 | 0.917 kg/m3 | ||||

| Pour Point | ASTM D97-17b | -18 ℃ | -21 ℃ | ||||

|

Copper Strip Corrosion

(3h/100℃) |

ASTM D130-18 | 1a Rating | 1a Rating | ||||

| Total Acid Number | ASTM D974 | 0.01(mg KOH/g) | 0.01(mg KOH/g) | ||||

| Carbon Residue Conradson | ASTM D189 | 0.01(% wt) | 0.01(% wt) | ||||

| Smell | Organoleptic | No Smell | No Smell | ||||

| End Product | Application of oil products |

| 80%~85% API Group I&II Base oil |

1. Directly sell by 200L barrels or truck-car.

2. Blending with compact additive to produce 5W, 10W, 15W lubricant oil for engines. 3. Blending to produce grease, SEA32, SEA46 hydraulic oil and other machine lube oil. |

| 5%~10% LGO |

1, Salable as fuel oil for burner providing to cement factory, glass factory, ceramic factory, electric power factory, steel making factory, boiler factory, etc.

2, Used to ethylene manufacturing. 3, Blending with asphalt to improve it's properties. |

| 5~10% Sludge oil |

1, Used to asphalt production

2, Sell as fuel oil for heavy machinery 3, Further processed by coking increasing the yield of light fuel oil. |

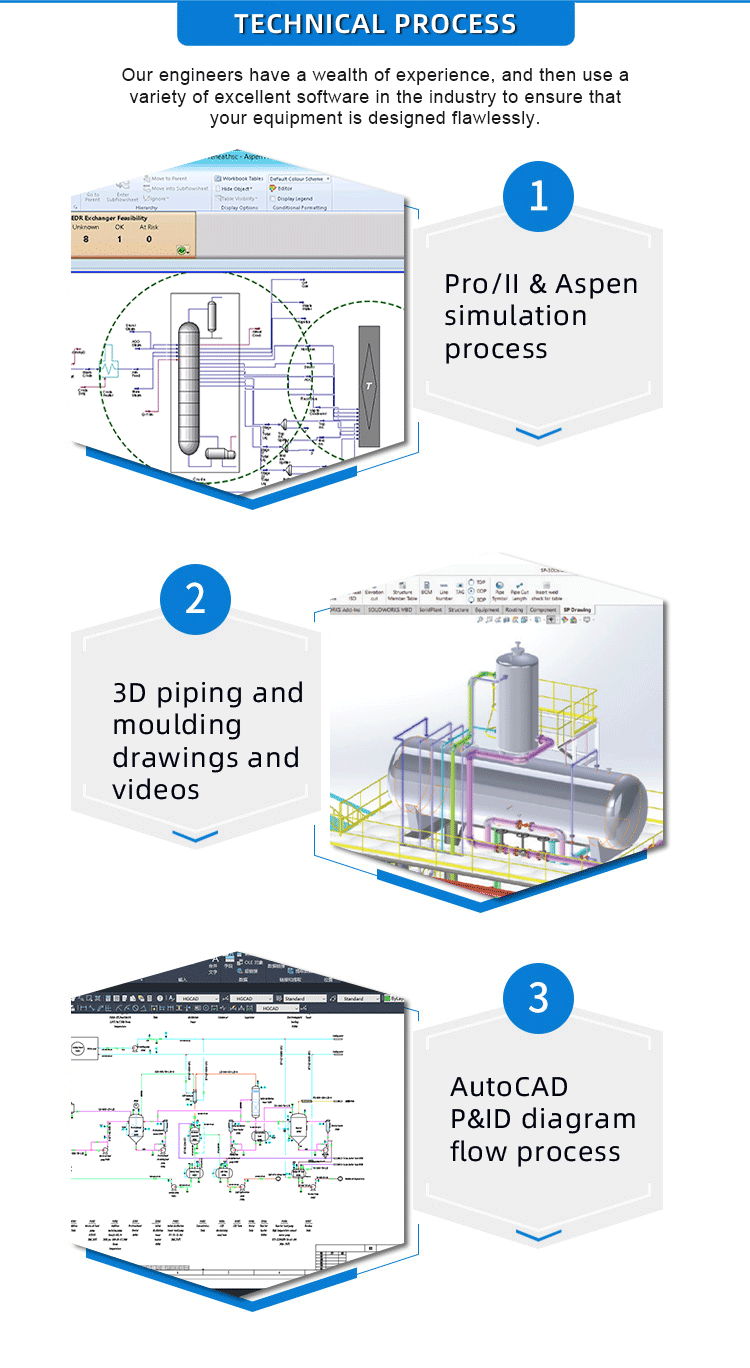

PurePath (Chongqing) Petroleum Engineering Technology Co., Ltd. (the Vpure) was founded in 2007 and headquartered in Jiulongpo, Chongqing, China. PurePath owns its unique engineers team to provide designs and manufactures complete, turnkey, skid mounted systems which recover near virgin API group I, API group II base oil and ultra low sulfur commerical standard diesel from waste lubricants. PurePath has been testing, engineering, designing, fabricating, installing and operating waste oil re-refining and distillation systems since its inception. Customized production plants also includes equipment such as desulfurization, decolorization and machine oil purifier for diesel and base oil. Our mission is to facilitate environmental restoration, resource recovery and pollution reduction through innovative technologies and design, construction, and operation of affordable state-of-the-art waste recovery systems.