- Product Details

- {{item.text}}

Quick Details

-

Name:

-

container board making machine

-

Raw material:

-

GI, PPGI

-

Control system:

-

PLC(imported Brand)

-

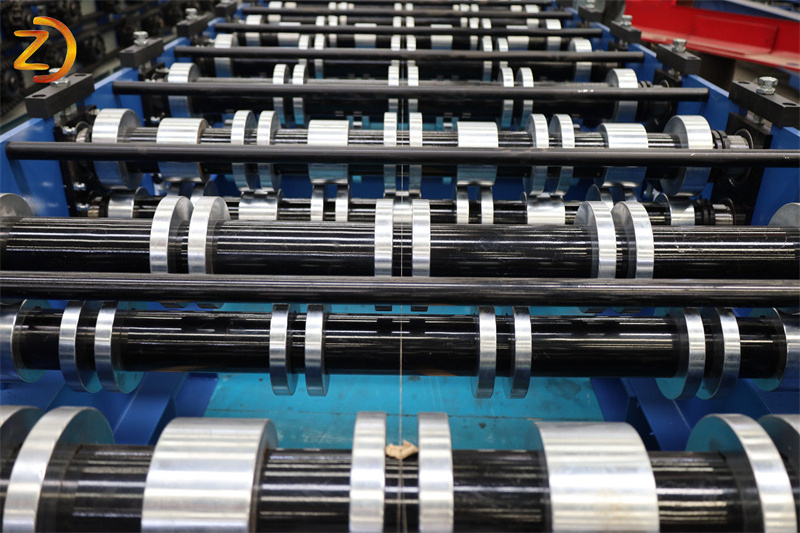

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# Steel Outer Diameter: 80mm

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Number Of Rollers:

-

11

-

Keyword:

-

Roof tile machine

-

Certification:

-

CE ISO

-

Advantage:

-

Cost Effective

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hener748

-

Weight (KG):

-

8000

-

Name:

-

container board making machine

-

Raw material:

-

GI, PPGI

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# Steel Outer Diameter: 80mm

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Number Of Rollers:

-

11

-

Keyword:

-

Roof tile machine

-

Certification:

-

CE ISO

-

Advantage:

-

Cost Effective

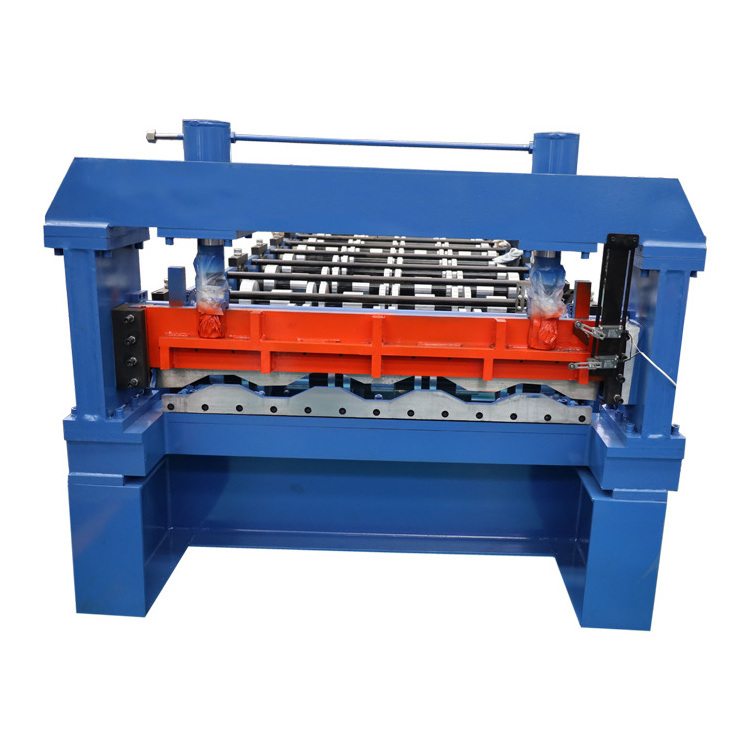

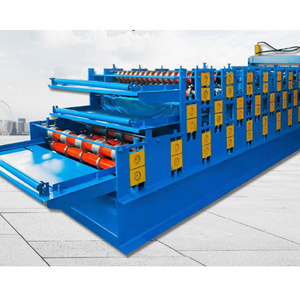

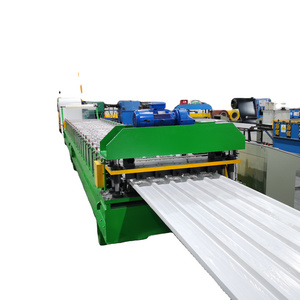

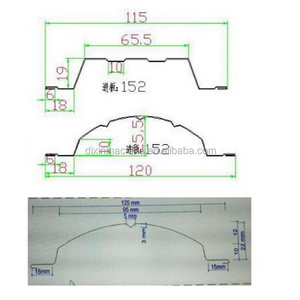

Steel shipping container metal sheet house prepainted sheet roll forming machine making machine

Product Features

1. More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can

get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life

of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

1. More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can

get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life

of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

We make machine frame by ourself

Before assemble,we check the machine frame every careful,including frame holes (that connected to the shaft), welding, so that we can g uarantee the frame quality

We are sprayed by professional staff who have more than 7 years spraying experience, so the machine will not appear to paint off after a period of time.

Machine parts

Decoiler

Our machine include one manual decoiler,capacity is

5 tons

,if you need more capacity ,we also have e

lectric and hydraulic decoilers, we can meet your requirements

Cutting blade

The material of the blade is GCR12 and hot treatment.

It adopts the

hydraulic drive and automatic

location to decide the dimension and cut the target products.

motor---Shanghai Lichao

Shanghai Lichao is famous brand ,the life is longer,don’t need always change the motor,and if it is broken, you can also find repairs shop locally

feeding plateform

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat,

parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

PLC--Delta

There are

5 languages

to choose from on the screen ,we can set the display language according to your requirements.

This will not delay your production schedule because of language

Chain

1 inch.

Specification

|

item

|

value

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant

|

|

Showroom Location

|

Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia

|

|

Condition

|

New

|

|

Type

|

Tile Forming Machine

|

|

Tile Type

|

Colored Glaze

|

|

Use

|

container

|

|

Production Capacity

|

10-15 m/min

|

|

Place of Origin

|

China

|

|

|

380v 50Hz

|

|

|

2400mm*1400mm*1400mm

|

|

|

8000kg

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Easy to Operate

|

|

Rolling thinckness

|

0.8-2mm

|

|

Feeding width

|

1000mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Motor, Bearing, Pump, Gearbox, PLC

|

|

Product name

|

container panel roll forming machine

|

|

Shaft material

|

High Grade Forged 45# Steel with 1st Rough Finishe

|

|

Material of rollers

|

High Quality Cr12 Quenched HRC58-62 °

|

|

Raw material

|

ppgi,ppgl,gi,gl

|

|

Roller stations

|

18 Stations

|

|

Control system

|

PLC

|

|

Decoiler

|

5 Ton Manual or as your requiment

|

|

Function

|

container

|

|

Raw Material Thickness

|

0.2-0.8mm

|

|

Capacity

|

30sets/Month

|

Packing & Delivery

Nude,use plastic packaged , which can effectively protect the machine from moisture during transportation.Use this package,you can use this machine making money immediately

Hot Searches