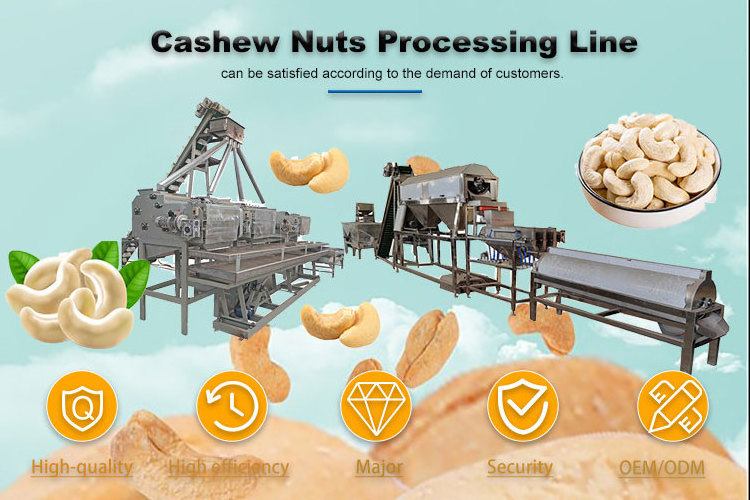

The cashew nut processing plant is a whole line for shelling cashew nuts and roasting cashew kernels. Fully-automatic cashew nut shelling and cashew kernel peeling machines save lots of labors.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SUNRISE

-

Voltage:

-

220V/380V, 380V

-

Dimension(L*W*H):

-

1.3*0.8*1.5m

-

Weight:

-

200 KG

-

Item:

-

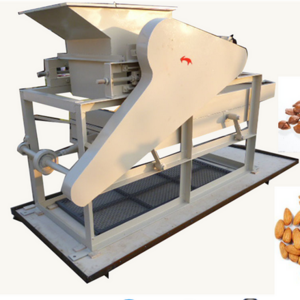

cashew nut shelling machine

-

Usage:

-

Shelling the cashew nut

-

Raw material:

-

Cashew nut

-

Color:

-

Silver

-

Function:

-

Removing Outer Hard Shell

-

Material:

-

Carbon Steel Stainless Steel

-

Suit for:

-

Size Nuts

-

Key words:

-

Shell Separation Machine

Quick Details

-

Type:

-

Automatic

-

Use:

-

Shelling

-

Production Capacity:

-

200-1000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SUNRISE

-

Voltage:

-

220V/380V, 380V

-

Dimension(L*W*H):

-

1.3*0.8*1.5m

-

Weight:

-

200 KG

-

Item:

-

cashew nut shelling machine

-

Usage:

-

Shelling the cashew nut

-

Raw material:

-

Cashew nut

-

Color:

-

Silver

-

Function:

-

Removing Outer Hard Shell

-

Material:

-

Carbon Steel Stainless Steel

-

Suit for:

-

Size Nuts

-

Key words:

-

Shell Separation Machine

Specification

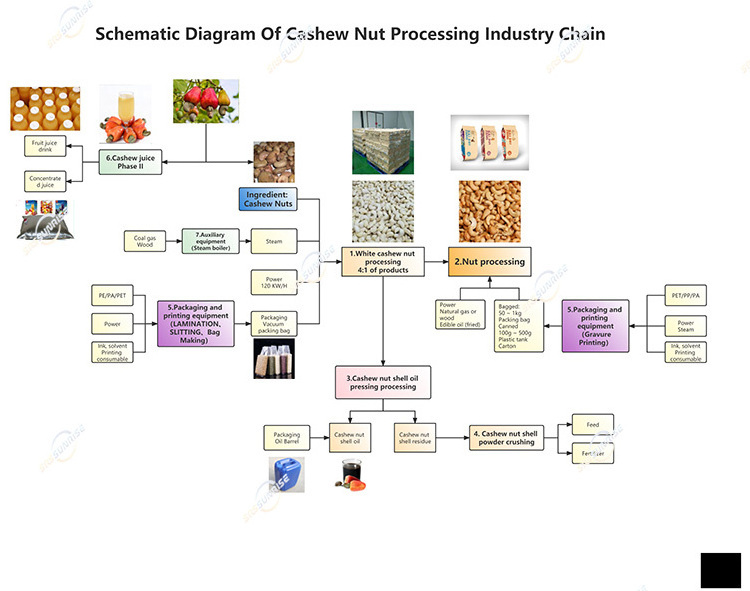

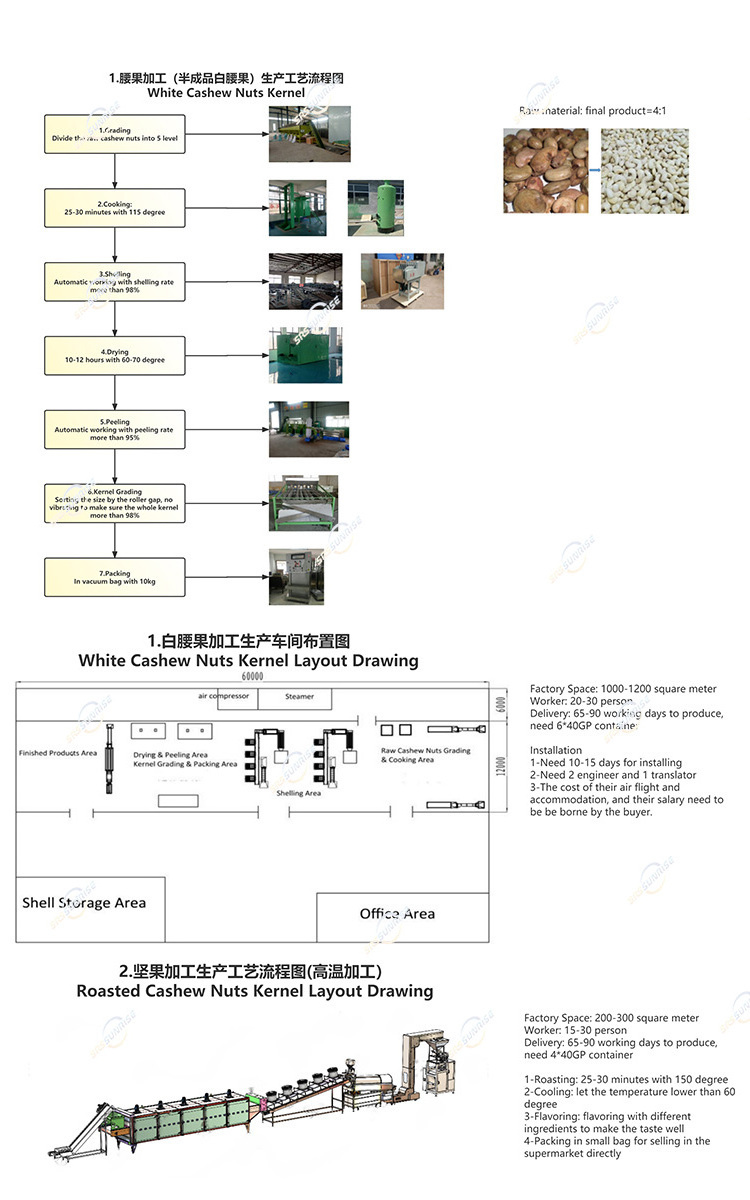

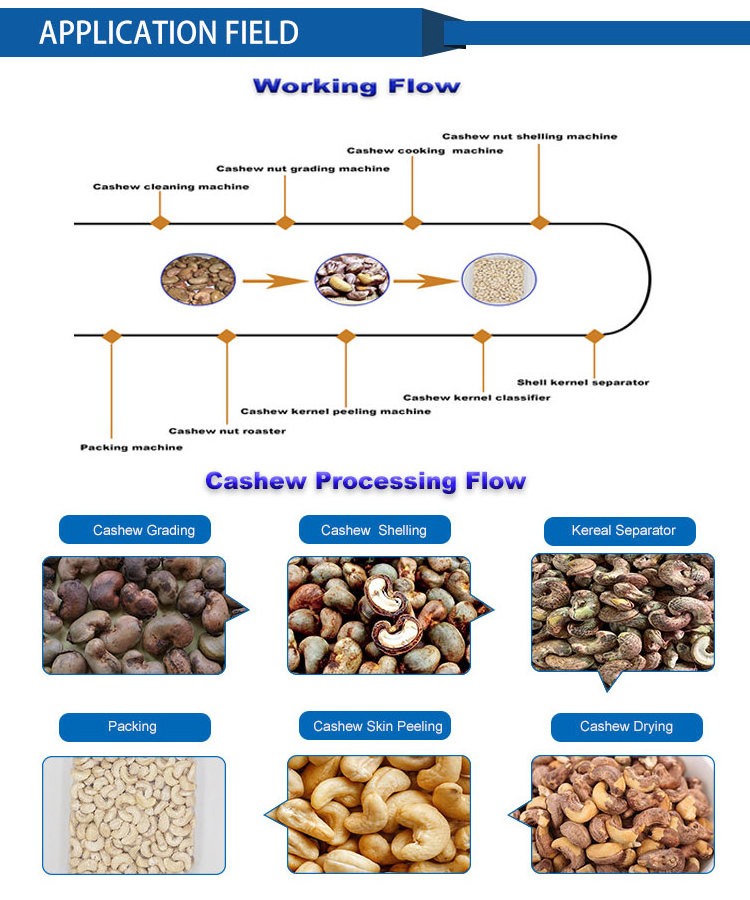

Introduction of Automatic Cashew Nut Processing Machine

1. Cashew Nuts Grading Machine

Cashew nut grading machine can classify raw cashew nuts into several levels on basis of size and dimension. Generally, cashew nut grading machine has three or four grades.

2. Cashew Nuts Cooking Machine

Raw cashew nuts in shell are steamed under pressure to soften the shells. The shell of cashew nut is very hard and it contains harmful oil ingredient. Cooked cashew nuts are easy to be cracked and shelled. The process of steam cooking helps in shelling cashew nuts with minimal effort.

3. Cashew Nuts Shelling Machine

Cooked cashew nuts are cracked in automatic cashew nut shelling machines. A roller bearing is used to adjust the distance between rollers for cashew nuts in a different size. The capacity of cashew nut shelling machine can reach 170 kg/h, and for cashew nut shelling line in 300 kg/h, we equip 2 shelling machines here.

4. Cashew Shell Kernel Separating Machine

This machine is used to separate cashew kernels from cashew shells and unshelled cashew nuts. After through cashew nut shelling machine, cashew shell pieces and kernels are separated by cashew shaker, and unshelled cashew nuts are returned to be re-shelled.

5 .Cashew Nut Peeling Machine

The red skin of each cashew kernel is removed by cashew kernel peeling machine for deep-processing products. This automatic cashew kernel peeling machine works with an air compressor and the internal parts of peeling machine are made from high-quality stainless steel.

6. Cashew Nuts Roasting Machine

Roasted cashew kernels have a beautiful appearance and good flavor. Cashew roaster is fully automatic and high efficient. In the roasting process, cashew kernels are heated evenly in high temperature and they would not stick on the inner wall.

Advantages of Cashew Nut Shelling Machine

1. Automatic cashew nut shelling line can finish all cashew nut processing steps from nut shelling, separating, peeling to roasting at one time.

2. All parts in Automatic cashew nut shelling line are controlled by PLC. Fully automatic design can save more and more working time and workforce when compared with manual cashew nut process.

3. The automatic cashew nut shelling line are made from carbon steel and stainless steel. It can have a long service life.

4. Adjustable distance between rollers can press cashew nuts in all size.

5. High efficiency in shelling and separating machine. The final perfect cashew kernels can reach 98%.

6. Advanced design ensures a low broken rate and low energy consumption.

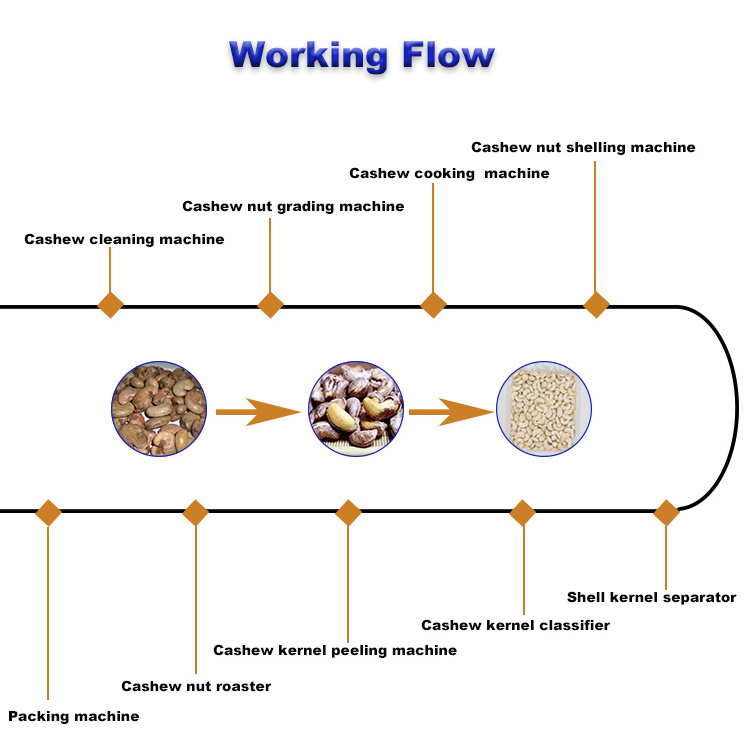

Cashew production line production process

cashew classifier (reduce breakage rate) - cashew nut cooker (reduce nut breakage rate) - cashew nut sheller - shell kernel separator - drying box / baking machine - cashew peeling machine - Nut grader - packaging machine

|

Item

|

Cashew Grading Machine

|

Cashew Grading Machine

|

Cashew Boiling Machine

|

Cashew Boiling Machine

|

Cashew Boiling Machine

|

|

Capacity

|

400-500 KG/H

|

1000 KG/H

|

Capacity

|

200-300 kg/h

|

500 kg/h

|

|

Power

|

1.1 KW

|

3 KW

|

Power

|

24 KW

|

48 KW

|

|

Weight

|

450 KG

|

1000 KG

|

Weight

|

150 KG

|

220 KG

|

|

Dimension

|

3.6*0.9*1.6 m

|

6*2*2.5 m

|

Dimension

|

1.5*0.5*1.55 m

|

1.5*0.5*1.55 m

|

|

Material

|

Carbon Steel

|

Carbon Steel

|

Material

|

Stainless Steel

|

Stainless Steel

|

|

Item

|

Cashew Shelling Machine

|

Cashew Shelling Machine

|

Cashew Shelling Machine

|

|

Model

|

YK-4

|

YK-6

|

YK-8

|

|

Capacity

|

50-60 kg/h

|

120-150 kg/h

|

200 kg/h

|

|

Cutting head

|

4 pieces

|

6 pieces

|

8 pieces

|

|

Motor power

|

0.75 kw

|

1.1 kw

|

1.1 kw

|

|

Weight

|

200 kg

|

300 kg

|

400 kg

|

|

Dimension

|

1.4*0.5*1.2 m

|

1.4*1.05*1.3 m

|

1.45*1.25*1.3 m

|

|

Material

|

Carbon steel

|

Carbon steel

|

Carbon steel

|

|

Cracking rate

|

95%

|

95%

|

95%

|

|

Item

|

Cashew Drying Machine

|

Cashew Drying Machine

|

|

Model

|

TD-120

|

TD-180

|

|

Heating type

|

Electric or Gas

|

Electric or Gas

|

|

Heating powder

|

30-45 kw

|

45-60 kw

|

|

Capacity

|

500-600 kg/batch

|

1000-1200 kg/batch

|

|

Size of tray

|

0.6*0.4 m

|

0.6*0.4 m

|

|

Size of car

|

0.65*0.45*1.5 m

|

0.65*0.45*1.5 m

|

|

No of car

|

8 sets

|

12 sets

|

|

No of tray

|

120 pieces

|

180 pieces

|

|

Weight

|

1200 kg

|

1700 kg

|

|

Dimension of machine

|

3.2*1.8*2.3 m

|

4.1*1.8*2.3 m

|

|

No of fan

|

0.75 kw*4=3 kw

|

0.75 kw*4=3 kw

|

|

Material

|

Stainless steel

|

Stainless steel

|

|

Item

|

Cashew Peeling Machine

|

Cashew Peeling Line

|

|

Capacity

|

100 KG/H

|

300-400 KG/H

|

|

Matched Air Compressor

|

7.5 KW

|

37 KW Screw Type Air Compressor

|

|

Peeling Rate

|

70-80%

|

80-90%

|

|

Weight

|

150 KG

|

1100 KG

|

|

Dimension

|

0.7*0.7*1.3 m

|

8*1.35*2.7 m

|

|

Material

|

Touching Raw Material Parts 304 Stainless Steel

|

Touching Raw Material Parts 304 Stainless Steel

|

|

Item

|

Cashew Roasting Cooling Machine

|

Cashew Roasting Cooling Machine

|

|

Model

|

RCM-2

|

RCM-3

|

|

Heating type

|

Gas or electric

|

Gas Or Electric

|

|

Gas or electric consume

|

10-15 kg/h 30-45 kw

|

15-20 kg/h

|

|

Capacity

|

300 kg/h

|

500-600 kg/h

|

|

Fan for hot air recycling

|

4 kw

|

5.5 KW

|

|

Cooling fan

|

3 kw

|

4 KW

|

|

Belt type

|

Plate belt

|

Plate Belt

|

|

Material of machine

|

304 stainless steel

|

304 stainless steel

|

|

Dimension

|

6.5*1.5*2.5 m

|

7.5*2.1*2.3 m

|

|

Weight

|

1800 KG

|

3500 KG

|

We can make appropriate adjustments to the machine according to the different needs of our customers. If you are interested in the machinery of the cashew series,please feel free to contact me. We welcome every customer to visit our factory.

Q1: What power do you use in your factory?-V,-Hz, 3 phase or single phase?

(Like 220 V , 50 Hz , single or 380 V, 50 Hz ,3 phase...etc)

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

we suggest using Alibaba trade assurance service for all transactions to protect your money

and ensure our service for you.

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

after production, we will provide detailed operating instructions, testing videos, certification

documents, etc. Alternatively, you can arrange a third-party inspector to do inspection and

give you report.

Q5: How about the after-sale service and guarantee period?

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

after-sale service starts from the date when you receive machine .

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

Hot Searches