- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±6mm

-

Voltage:

-

AC110-200V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HG

-

Dimension(L*W*H):

-

customizable

-

Weight:

-

KG

-

Equipment model:

-

HG-24-24-10

-

Capacity:

-

6000BPH-8000BPH

-

Bottle material:

-

Glass Bottle

-

Bottle height:

-

120-360mm

-

Pressure of air supplier:

-

0.7MPa

-

Touch screen:

-

PLC

-

Consumption tolerance:

-

1.5 M3/min

-

Washing water pressure:

-

0.2~0.25MPa

-

Power:

-

7.5kw

-

Filling capacity:

-

6000-8000 BPH

Quick Details

-

Machinery Capacity:

-

8000BPH, 6000BPH

-

Packaging Material:

-

Metal

-

Filling Material:

-

Beer

-

Filling Accuracy:

-

±6mm

-

Voltage:

-

AC110-200V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HG

-

Dimension(L*W*H):

-

customizable

-

Weight:

-

KG

-

Equipment model:

-

HG-24-24-10

-

Capacity:

-

6000BPH-8000BPH

-

Bottle material:

-

Glass Bottle

-

Bottle height:

-

120-360mm

-

Pressure of air supplier:

-

0.7MPa

-

Touch screen:

-

PLC

-

Consumption tolerance:

-

1.5 M3/min

-

Washing water pressure:

-

0.2~0.25MPa

-

Power:

-

7.5kw

-

Filling capacity:

-

6000-8000 BPH

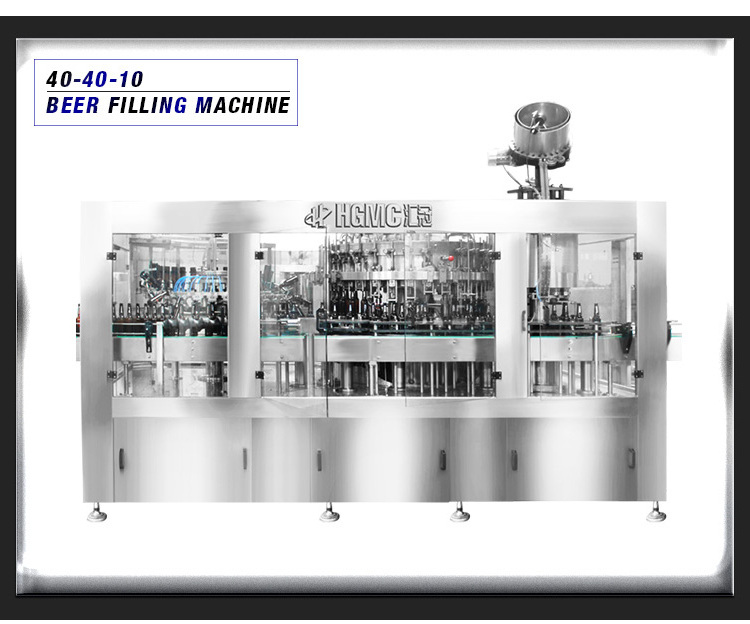

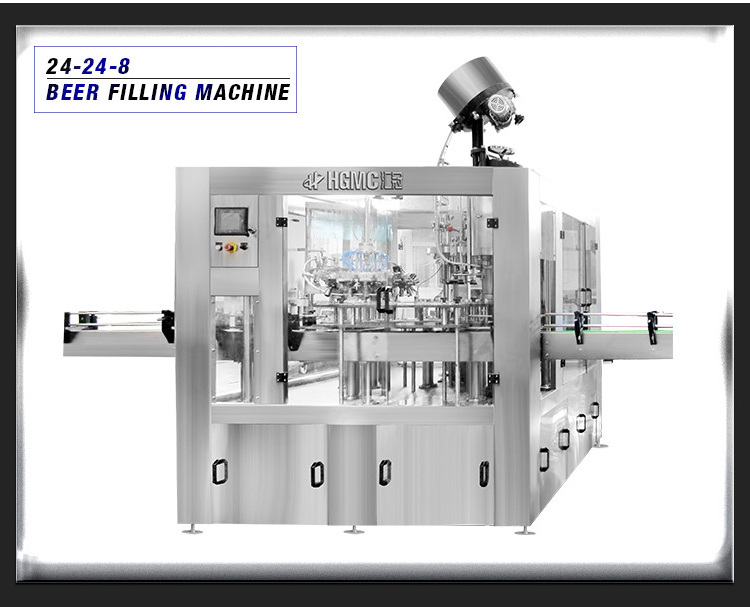

24-24-8 Complete Full Automatoc Craft Beer Beveage Glass Bottle Rinsing Filling Capping Labeling Machine

|

Item

|

Parameter

|

|

Equipment model

|

HG-CGF-24/24/8

|

|

Washing nozzles

|

24

|

|

Filling nozzles

|

24

|

|

Capping nozzles

|

8

|

|

Bottle material

|

Glass Bottle

|

|

Bottle height

|

120-360mm

|

|

Bottleneck diameter

|

φ50-φ120mm

|

|

Pressure of air supplier

|

0.7MPa

|

|

Consumption tolerance

|

1.5 M3/min

|

|

Washing water pressure

|

0.2~0.25MPa

|

|

Power

|

7.5kw

|

|

Filling capacity

|

6000-8000 BPH

|

|

Weight

|

6.5 ton

|

24-24-10 beer bottle filling machine

Glass bottle rinsing/filling/capping 3-in-1 Unit is a kind of professional filling machine integrator for beer filling It is multifunctional which can be used for washing, filling and capping. It is a kind of advanced filling machine integrator which is innovated following the process requirements of filling beer based on the importing and assimilating the foreign advanced technology. It is applied mostly in washing, filling, and capping plastic cap for beer, water and soft drink. It is the perfect selection to a large or medium-size brewery due to its reasonable configuration, security of operation, dependability of running and its so convenient maintenance.

Product advantages :

1). The machine is our patent product.

2). It adopts true sense of isobaric filling principle and filling valve adopts high precision mechanical valve. It has advantages of fast filling speed, high precision in liquid level. Adopt Siemens automatic controlling system, realizing trinity of the machines, and control the washing, filling and capping process.

3). Filling part:

No bottle, no filling:The machine only starts to fill when there is bottle. It will avoid the waste of the bottle and beer and the waste of the beer is less than 0.8%.

The filling valve uses an external valve for true isostatic filling

The machine can achieve twice vacumming and twice co2 injection to keep beer quality.

4). Capping part:

The capping part can be designed according to the customers demand on the cappers

To realize the no bottle no caps offering.

5). Foaming decive:

Equipped with foam device according to customer's requirements

High pressure water injection to push out the air of the bottle neck to keep the beer quality.

6). PLC

The PLC from SIEMEMS. It has the advantages of perfect function, strong applicability and easy to learn and use.

FAQ:

2.Q: Do you have a professional engineer or after-sales team in our country?

A: Yes, our equipment is sold to 150 countries and areas and we have our local after-sales service personnel in Europe, America and Asia.

3.Q: How long is the delivery time?

A: The delivery time of beer equipment is 30-50 working days, the delivery time of filling machine is 45-50 working days.

4.Q:What payment methods are supported?

A:T/T, L/C, Credit Card, VISA, Apple device, Western Union.

5. Q: How long the warranty will be?

A: 3 years warranty for the whole tank and the main equipment, 1 year for the accessories and auxiliaries. 1 Year warranty for filling machine.

6. Q: How about the installation and training?

A: We can supply the installation and training. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

7.Q: Can I be your company's sales agent?

A: Yes, it’s our pleasure. We very much welcome you to join us. Please contact us to discuss specific details.

8).

The price does not include electrical appliances, etc.

Hot Searches