- Product Details

- {{item.text}}

Quick Details

-

Body:

-

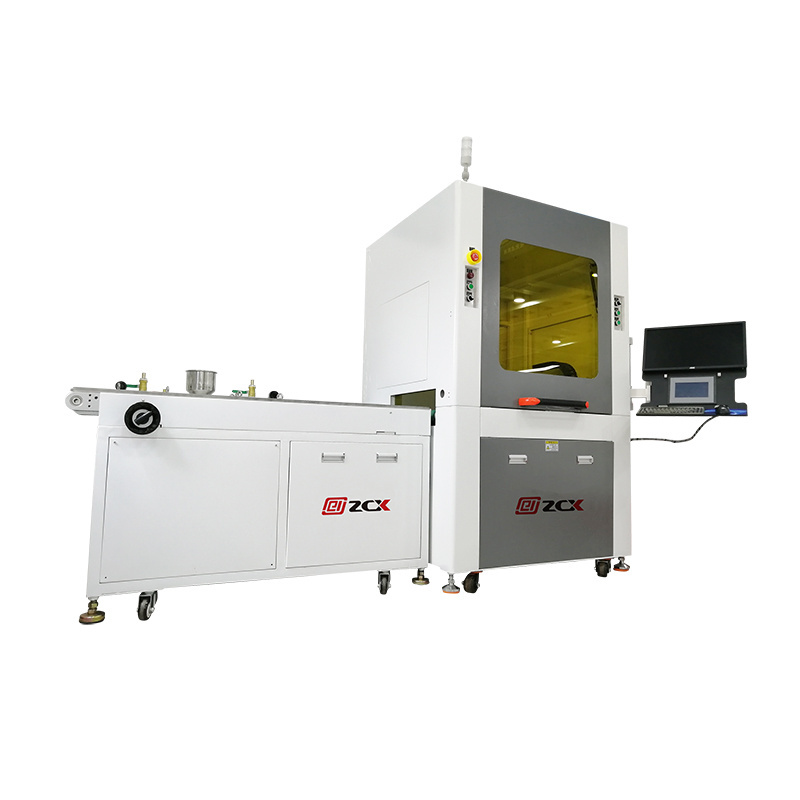

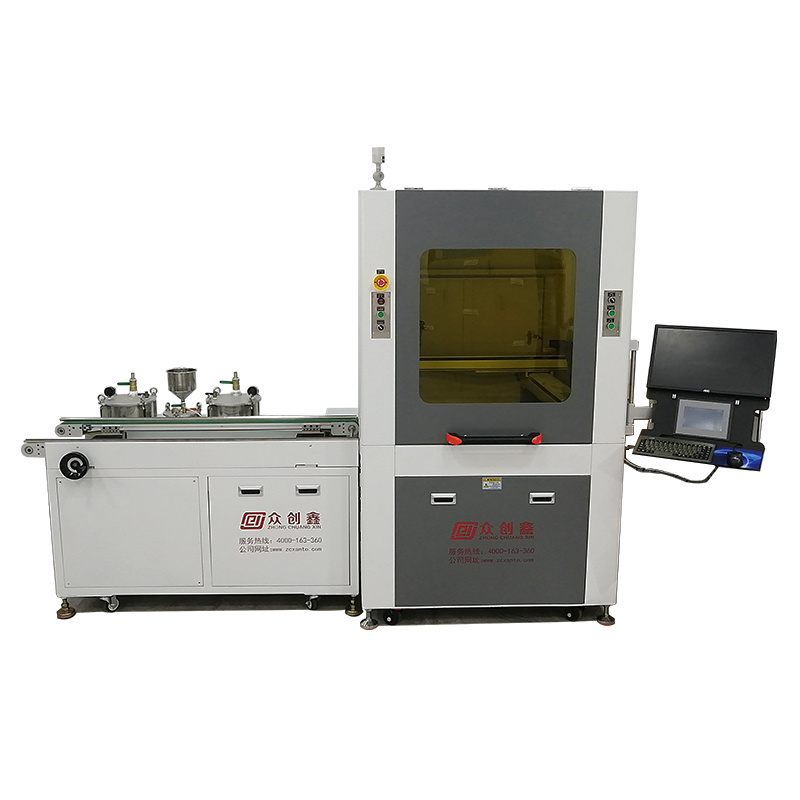

Sheet metal welding+Marble terrace

-

Product Maximum Size:

-

450*1200mm

-

XYZ Working Area:

-

700*600*50mm

-

Chain Speed:

-

0~500mm/s

-

Running Speed:

-

X/Y 1000mm/s, Z 500mm/s

-

Running Precision:

-

±0.02mm

-

XYZ Drive Mode:

-

Servo Motor+Ball Screw Rod

-

Programming Mode:

-

CCD Visual Programming

-

Net Weight:

-

About 600KG

Quick Details

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

ZCX

-

Voltage:

-

220V

-

Body:

-

Sheet metal welding+Marble terrace

-

Product Maximum Size:

-

450*1200mm

-

XYZ Working Area:

-

700*600*50mm

-

Chain Speed:

-

0~500mm/s

-

Running Speed:

-

X/Y 1000mm/s, Z 500mm/s

-

Running Precision:

-

±0.02mm

-

XYZ Drive Mode:

-

Servo Motor+Ball Screw Rod

-

Programming Mode:

-

CCD Visual Programming

-

Net Weight:

-

About 600KG

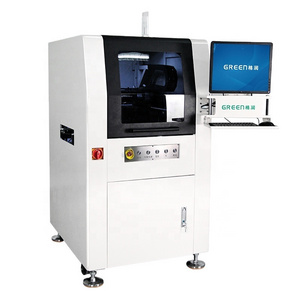

SMT Equipment High Speed Automatic PCB/LED Lens Adhesive Intelligent CCD Visual Glue Dispenser

|

Technical items |

Technical parameters |

|

Glue ratio |

Single component |

|

Glue viscosity |

≤100,000 CPS |

|

Glue valve |

spray valve |

|

Minimum spray rate |

0.05mg |

|

Dispensing speed |

800 s (max) |

|

Glue packaging |

30ml |

|

Camera |

Da Heng |

|

Coaxial light source |

PPX-CO30 |

|

Precision of dispensing |

Glue volume deviation ±1%, |

|

Work schedule |

650(X)*300(Y)*80(Z) mm |

|

Running speed |

X axis Y axis 800 mm /s (max), Z axis 300 mm/s (max) |

|

Operational accuracy |

±0.02 mm( displacement) |

|

Running track |

Points, straight lines, boxes, circles, arcs, graphics |

|

Input pressure range |

0.5-0.8 MPa |

|

Head seal compression |

≤2.6 Mpa |

|

Mode of operation |

Automatic, manual |

|

Programming |

CCD Visual Programming |

|

Electronic control system |

Intelligent motion control card + industrial computer +PLC+ visual software (program setting, modification, storage, etc.) |

|

Dimensions |

approximately L800*W900*H1400 mm |

|

Total weight |

Approximately 650 KG |

|

Rated Power Supply |

220V 50Hz approximately 3.5 K W |

This glue dispensing & coating machine is suitable for high efficiency, high operation precision, high glue proportion production process; mainly used in: LED lens, crafts, label signs, wall stickers, electronic products and other industries glue dispensing process.

Main features:

1. Special injection dispensing system, CCD system automatically corrects product positioning, wh

ich has significant advantages in dispensing efficiency.

2. XY axis are equipped with high-speed linear motor to achieve high-precision parts dispensing

and high-speed dispensing efficiency.

3. Use a thick marble platform to ensure smoothness at high speed dispensing.

4. Support high-speed injection valve to achieve faster and more accurate dispensing, thus broa

dening the scope of application.

5. The system is specially designed for the Lens assembly of LED Bars and the fully automated

online jet dispensing system developed by the electronics industry for high precision dispensing

applications.

6. The length less than 600mm of LED light bar can be properly handled, and the longest can

reach 1200mm length.

7. With the chain conveying function, it can effectively dock the front and rear end stations.

Dispensing valve principle & structure:

There are variaty of configurations for different technique processing. Different glue and glue ratio,substrate,surface, program or dispensing type may effect on the configurations of the machine.

So provide glue TDS to us is important.

1. Plenty options of configurations

2. Fit for various of glue

3. Match for most of processing of production

We have well experienced sales man, please do not hesitate to tell him your requirments, they will provide you the best solution right now!

Features:

1. Special injection dispensing system, CCD system automatically corrects product positioning, wh

ich has significant advantages in dispensing efficiency.

2. XY axis are equipped with high-speed linear motor to achieve high-precision parts dispensing

and high-speed dispensing efficiency.

3. Use a thick marble platform to ensure smoothness at high speed dispensing.

4. Support high-speed injection valve to achieve faster and more accurate dispensing, thus broa

dening the scope of application.

5. The system is specially designed for the Lens assembly of LED Bars and the fully automated

online jet dispensing system developed by the electronics industry for high precision dispensing

applications.

6. The length less than 600mm of LED light bar can be properly handled, and the longest can

reach 1200mm length.

7. With the chain conveying function, it can effectively dock the front and rear end stations.