- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/3PH/50HZ

-

Dimension(L*W*H):

-

7.8*2.9*5.4m

-

Screw diameter (mm):

-

80 mm

-

Screw Heating Power(kW):

-

8 kW

-

Extruder Motor Power(kW):

-

30 kW

-

Mold Platen Size(Width)(mm):

-

550 mm

-

Mold Platen Size(Height)(mm):

-

650 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

5 kW

-

Accumulator Capacity(L):

-

4 L

-

Power (kW):

-

50

-

Weight (T):

-

11

-

Max. Size of mold(W*H):

-

1200*1720mm

-

Max. Die diameter:

-

620mm

-

Material application:

-

PP/PE/LDPE/HDPE/LLDPE/ABS/PS

-

Delivery time:

-

Within 90 working days

-

Packing:

-

PE film, Wooden box, Wooden/Steel base

-

Shipping:

-

By sea or by train

-

Weight:

-

35TON

-

Power:

-

22kW

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE& ISO900

Quick Details

-

Clamping Force (kN):

-

215

-

Output (kg/h):

-

110 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V/3PH/50HZ

-

Dimension(L*W*H):

-

7.8*2.9*5.4m

-

Screw diameter (mm):

-

80 mm

-

Screw Heating Power(kW):

-

8 kW

-

Extruder Motor Power(kW):

-

30 kW

-

Mold Platen Size(Width)(mm):

-

550 mm

-

Mold Platen Size(Height)(mm):

-

650 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

5 kW

-

Accumulator Capacity(L):

-

4 L

-

Power (kW):

-

50

-

Weight (T):

-

11

-

Max. Size of mold(W*H):

-

1200*1720mm

-

Max. Die diameter:

-

620mm

-

Material application:

-

PP/PE/LDPE/HDPE/LLDPE/ABS/PS

-

Delivery time:

-

Within 90 working days

-

Packing:

-

PE film, Wooden box, Wooden/Steel base

-

Shipping:

-

By sea or by train

-

Weight:

-

35TON

-

Power:

-

22kW

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE& ISO900

220 liter 200 liters calcium hypochlorite 45kg plastic drum blow molding machine

Extrusion blow molding machine technical specification:

|

Max. Product Volume |

(L) |

250L |

|

Dry cycle |

(pc/h) |

300 |

|

Screw Diameter |

(mm) |

120 |

|

Screw L/D ratio |

(L/D) |

32 |

|

Screw drive power |

(KW) |

132 |

|

Screw heating capacity |

(KW) |

16.2-23.6 |

|

No. of heating zone(screw) |

(ZONE) |

5 |

|

Max. Output of HMWHDPE |

(Kg/hr) |

320-380 |

|

Oil pump drive power |

(KW) |

22 |

|

Clamping force |

(KN) |

770 |

|

Mold stroke (Platen distance) |

(mm) |

800~1800 |

|

Max. Size of Mold(W*H) |

(mm) |

1200*1720 |

|

Capacity of the die head |

(L) |

22 |

|

Max. Die diameter |

(mm) |

620 |

|

Die heat capacity |

(KW) |

15 |

|

No. of heating zone |

(ZONE) |

6 |

|

Blowing pressure |

(Mpa) |

1.0 |

|

Air volume |

(M3/MIN) |

2.0 |

|

Cooling water pressure |

(Mpa) |

0.3 |

|

Water consumption |

(L/MIN) |

300 |

|

Size of machine ( L*W*H) |

(m) |

7.8*2.9*5.4 |

|

Weight of machine |

(TON) |

35 |

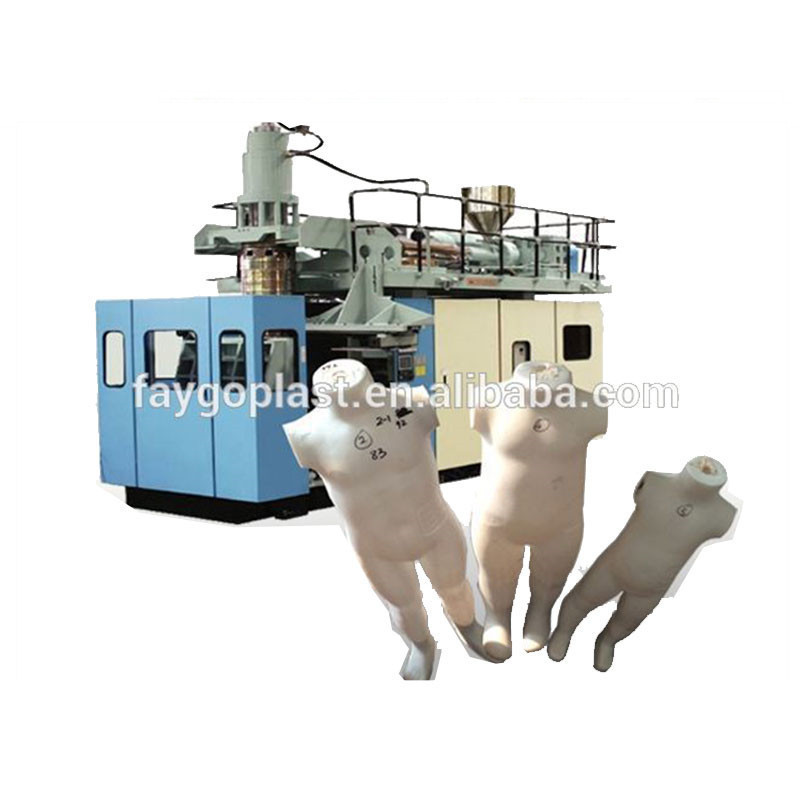

Extrusion blow molding machine samples:

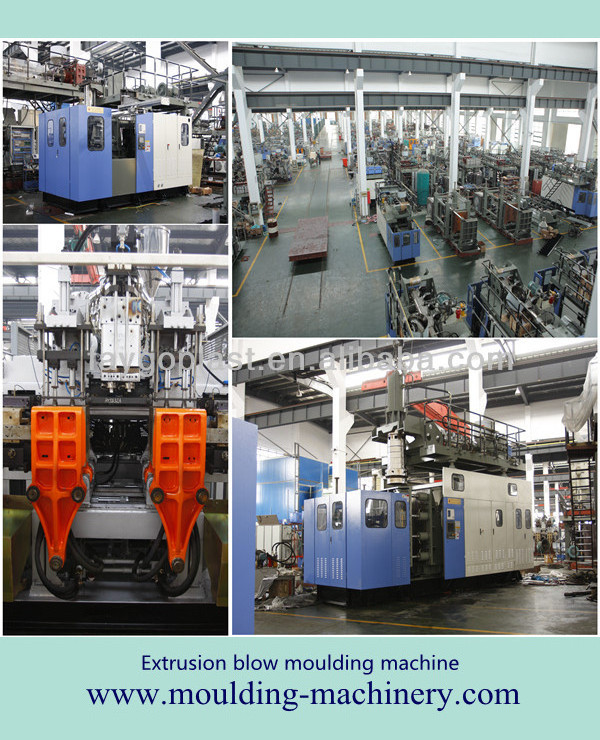

Extruson blow molding machine suppliers of main parts:

a) Hydraulic Parts

|

Name |

Supplier |

|

Oil Pump |

PARKER or SUNNY, America |

|

Valve |

YUKEN or SUNNY |

|

Hose, Joint |

PARKER SIR |

|

Sealer |

Top DZ Europe |

b) Electrical Parts

|

Name |

Supplier |

|

Microcomputer Control System |

MITSUBISHI PLC, Japan |

|

Touch Screen |

HITECH color screen, Taiwan |

|

Temperature Controller |

MITSUBISHI, Japan |

|

Conductor |

SCHNEIDER |

|

Air Switch |

SCHNEIDER |

|

Motor |

SIMENS BEIDE Asynchronous Motor |

|

Power Resource |

MEAN WELL, Taiwan |

|

Inverter |

MITSUBISHI |

c) Pneumatic Parts

|

Name |

Supplier |

|

Solenoid Valve |

, Germany |

|

Cylinder |

, Germany |

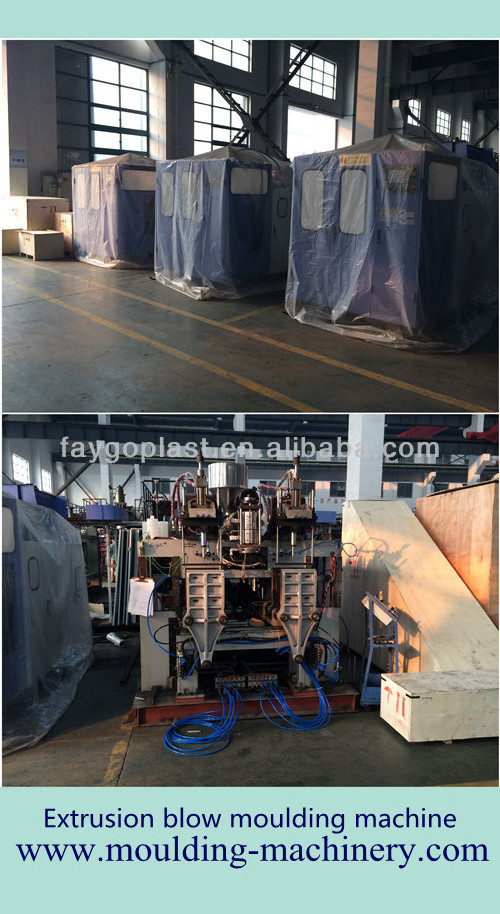

Extrusion blow molding machine shipping and workshop:

Extrusion blow molding machine technical feature:

The electronic control system : Japan's Mitsubishi PLC computer and human-machine interface (English or Chinese) control, color touch-screen operation. All the process set to change, retrieval, monitoring, troubleshooting and other functions are implemented on the touch screen, no point of contact with the working principle, components and durable.

The hydraulic system : proportional pressure control, with imported brands Yuken hydraulic components, stable and reliable.

The plasticizing system : efficient plastics mixing screw, to ensure plasticizing full uniform.

The speed control system : VVVF + alloy steel and hard gear reducer, speed stable, low noise, durable.

The opening and closing mold, mold transfer system : beam arm, three position, center locking clamping mechanism, to ensure long-term use. Clamping force balance, no deformation, the use of body translation mode (ball linear guide), high precision, low resistance, fast.

Blowing the needle holder : blow the whole Square-type needle holder, a solid does not shift to ensure a smooth incision products.

Extrusion blow molding machine installation, commissioning and training:

If the buyer needs seller to send technicians to workshop for supervising the erection and start-up, seller must support and send sufficient number of technicians and keep duration of stay in workshop. Usually it’s about 3~5 days in this duration. The first day is that when our technician is at the airport to factory of buyer. And from the first day, the buyer has to pay US$80 per day. And all accommodation, visa application & air ticket will be born by the buyer.