- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YIHUI

-

Year:

-

2021

-

Voltage:

-

3 phase 220V /380V

-

Dimension(L*W*H):

-

1250x950x2450 mm

-

Weight (T):

-

1850 T

-

Model Number:

-

YHA4-25T

-

Motor Power (kw):

-

3.75 kw

-

Marketing Type:

-

Hot Product

-

Structure:

-

4 column type

-

Usage:

-

Edge trimming

-

Application:

-

For all kinds of alloy die cast products.

-

Pillars:

-

Chrome plated and harden processing.

-

Control:

-

With PLC

-

Customized:

-

Available

-

Function:

-

Trimming, bending, stamping, etc.

-

Term:

-

Manufacturer

-

Color:

-

As required

-

Nominal Force (kN):

-

250

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

300

-

Return Force (kN):

-

250 kN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YIHUI

-

Year:

-

2021

-

Voltage:

-

3 phase 220V /380V

-

Dimension(L*W*H):

-

1250x950x2450 mm

-

Weight (T):

-

1850 T

-

Model Number:

-

YHA4-25T

-

Motor Power (kw):

-

3.75 kw

-

Marketing Type:

-

Hot Product

-

Structure:

-

4 column type

-

Usage:

-

Edge trimming

-

Application:

-

For all kinds of alloy die cast products.

-

Pillars:

-

Chrome plated and harden processing.

-

Control:

-

With PLC

-

Customized:

-

Available

-

Function:

-

Trimming, bending, stamping, etc.

-

Term:

-

Manufacturer

-

Color:

-

As required

-

Nominal Force (kN):

-

250

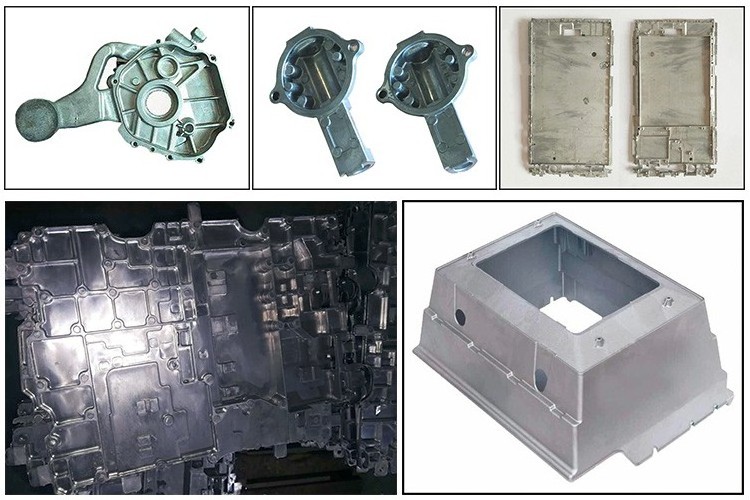

Product Application

1) Edge trimming and shaping for all kinds of aluminum alloy die castings and magnesium alloy die castings.

2) Most widely used in fields like aluminum magnesium alloy mobile phone products, automobile and motorcycle parts die casting.

3) Shaping and trimming for metal or nonmetal.

Main Features

1) Using built-in high speed cylinder, has fast falling speed and high production efficiency.

2) Four columns are made of high-strength alloy steel with hard chrome plated surface and good abrasion resistance.

3) Pressure, stroke and pressurizing time can be adjusted according to processing requirement.

4) Optional configuration: protective cover, anti-drop device, blowing chip removal device, LED lighting and infrared grating, etc.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Global Market

Customers Show

Main parts and advantage:

1. Working table is made of No. 45 steel. It is processed with heating treatment and precision grinding, so it has good flatness and good hardness, and there is no deformation.

2. Columns are made of high-strength alloy steel. The column surface is hard chrome plated and processed with medium-frequency treatment. It has very good oriented capability and abrasion resistance.

3. Piston is made of seamless steel. The surface of the piston is hard chrome plated and processed with medium-frequency treatment. Therefore it possesses good hardness and high strength. And the speed is fast with mother-son type structure.

4. Oil circuit is integrated manifold block type and it is easy for maintenance and repair.

5. Oil tube is clip-on type. Comparing with traditional welded type, there is no oil leakage.

6. Main machine constitution is made of A3 (common carbon steel). The machine base is one-piece bending type, so it is strong and stable.

Guarantee from YIHUI:

1. YIHUI has 20 years of experience in manufacturing hydraulic press.

2. We have cooperated with many famous companies from more than 25 countries.

3. Main components are imported from Germany, Italy, Japan, Taiwan, and domestic famous brands. Quality is guaranteed.

4. We are able to supply the whole production line service including molds, technical support and other relative machines.

5. We have received CE, ISO, SGS certificates.

|

Packaging

|

|

|

|

Size

|

Accordingly

|

|

|

Weight

|

Accordingly

|

|

|

Packaging Details

|

The normal package is wooden case(Size: L*W*H). The wooden case will be fumigated if needed. If container is too tight, we will use PE film for packing or pack it according to customers special request.

|

|

|

|

|

|

|

|

|

|

150 Ton Gas Stove Body Making Double Action Deep Drawing Servo Hydraulic Metal Forming Press

1 00% Response Rate

Aluminum Casing Backward Extrusion 500 Ton Hydraulic Servo Press Cold Forming Machine

100% Response Rate