- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

13 kN

-

Theoretical Shot Volume(cm³):

-

75 cm³

-

Injection Rate (g/s):

-

77 g/s

-

Injection Weight (g):

-

67 g

-

Screw Speed (rpm):

-

1 - 200 rpm

-

Screw diameter (mm):

-

30 mm

-

Screw L/D Ratio:

-

21

-

Distance between Tie Bars:

-

330 X 200

-

Weight (KG):

-

850 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

300 mm

-

Model Number:

-

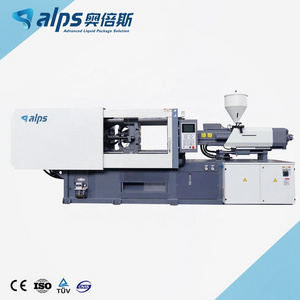

CY-300ST-2L

-

Brand Name:

-

Canyang

-

Power (kW):

-

3.75 kW

-

Clamping force:

-

30 tons

-

safe shot weight(PS):

-

2.4 OZ

-

number of temperature control:

-

3

-

injection pressure:

-

896 kg/cm³

-

Nozzle Contact Force:

-

4.45 T

-

Nozzle Retraction Stroke:

-

130 mm

-

Max.Hydraulic Pressure:

-

140 kg/cm²

-

Pump Output:

-

29.5 I/min

-

Machine Dimensions(L*X*H):

-

1.4x0.9x2.37 m

Quick Details

-

Plasticizing Capacity(g/s):

-

49

-

Mold Height(mm):

-

200 - 500 mm

-

Ejector Stroke(mm):

-

35 mm

-

Ejector Force(kN):

-

13 kN

-

Theoretical Shot Volume(cm³):

-

75 cm³

-

Injection Rate (g/s):

-

77 g/s

-

Injection Weight (g):

-

67 g

-

Screw Speed (rpm):

-

1 - 200 rpm

-

Screw diameter (mm):

-

30 mm

-

Screw L/D Ratio:

-

21

-

Distance between Tie Bars:

-

330 X 200

-

Weight (KG):

-

850 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

300 mm

-

Model Number:

-

CY-300ST-2L

-

Brand Name:

-

Canyang

-

Power (kW):

-

3.75 kW

-

Clamping force:

-

30 tons

-

safe shot weight(PS):

-

2.4 OZ

-

number of temperature control:

-

3

-

injection pressure:

-

896 kg/cm³

-

Nozzle Contact Force:

-

4.45 T

-

Nozzle Retraction Stroke:

-

130 mm

-

Max.Hydraulic Pressure:

-

140 kg/cm²

-

Pump Output:

-

29.5 I/min

-

Machine Dimensions(L*X*H):

-

1.4x0.9x2.37 m

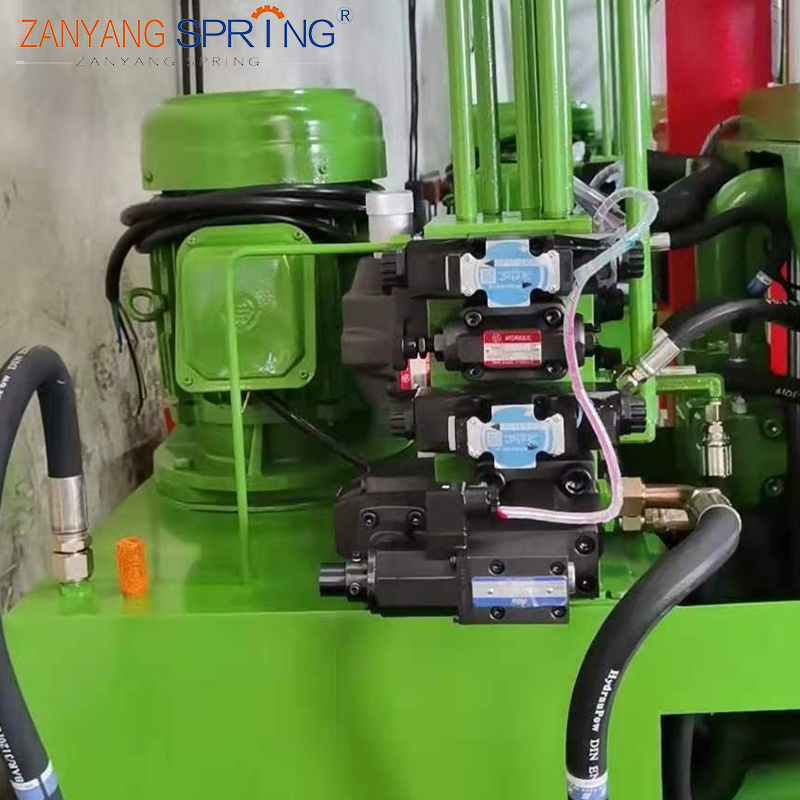

1. Vertioncal RETRACTABLE screw injection unit .

2. 2 or 3 barrer temperature control zones.

Independent settings for screw speed,injection pressure,and back pessure assure excellent REPEATABILITY and precise control.

3. Stationary lower half with hydraulic ejection assures a vIbration free work area.

4. Low pressure control standard.

5. The CY-S2 Series may be purchased with a shuttle table or with a single mold slide to move the work into an open area for ease of loading, unloading or autmation through the use robotics or special equiment.

| MODEL | UNIT | CY-300ST-2L | CY-400ST-2L | CY-500ST-2L | ||||||

| INJECTION UNIT | Screw Diameter | mm | 28 | 30 | 26 | 28 | 30 | 30 | 32 | 35 |

| lnjection Pressure | kg/cm2 | 1019 | 896 | 1410 | 1220 | 1060 | 1245 | 1095 | 915 | |

| Theoretical Shot Volume | cm3 | 64.6 | 74 | 61 | 70.8 | 81 | 81 | 92 | 110 | |

| Max.Shot Weight(ps) | g | 58 | 67 | 56 | 65 | 74 | 74 | 85 | 102 | |

| Safe Shot Weight(ps) | OZ | 2.0 | 2.4 | 2.0 | 2.3 | 2.6 | 2.6 | 3.0 | 3.6 | |

| Injection Rate | cm3/sec | 67 | 76.7 | 55 | 63 | 73 | 67 | 76 | 91 | |

| Screw Stroke | mm | 105 | 115 | 115 | ||||||

| Screw Speed Max. | rpm | 0-200 | 0-205 | 0-190 | ||||||

| Nozzle Comtact Force | tons | 4.45 | 4.45 | 4.45 | ||||||

| Nozzle Retraction Stroke | mm | 130 | 170 | 190 | ||||||

| Number of Temperature Control | 3 | 3 | 3 | |||||||

| CLAMPING UNIT | Clamping Force |

tons

KN |

30

300 |

40

400 |

50

500 |

|||||

| Platen Size | mm | 480×310 | 540×380 | 580×430 | ||||||

| Tiebar distance | mm | 320×160 | 375×205 | 410×250 | ||||||

| Min.Mold Height | mm | 100/40 | 158/58 | 220/70 | ||||||

| Opening Stroke | mm | 300 | 350 | 350 | ||||||

| Max.Open Daylight | mm | 280/220 | 338/238 | 420/270 | ||||||

| Ejetor Force | tons | 1.3 | 1.3 | 1.76 | ||||||

| Ejetor Stoke | mm | 35 | 35 | 35 | ||||||

| POWER/HEADING UNIT | Max.Hydaulic Pressure | kg/cm2 | 140 | 140 | 140 | |||||

| Pump Output | l/min | 29.5 | 34.5 | 37.2 | ||||||

| Oil Resservoir Capacity | l | 100 | 100 | 130 | ||||||

| Cooling Waer Consumption | l/hr | 400~600 | 400~600 | 600~800 | ||||||

| Pump Motor Power | kW/HP | 3.7/5HP | 3.7/5HP | 5.5/7.5HP | ||||||

| Berrel Heating Power | kW | 1.8 | 2.4 | 2.8 | ||||||

| Total electricity usage | kW | 5.5 | 6.3 | 9 | ||||||

| OTHER | Machine Weight | tons | 0.85 | 1.05 | 1.45 | |||||

| Machine Dimensions(LxWxH) | m | 1.25 x 0.9 x 2.17 | 1.35x 1 x2.25 | 1.48 x 1.1 x2.37 | ||||||

| Shipping Weight | tons | 0.93 | 1.15 | 1.58 | ||||||

| Shipping Measurements(LxWxH) | m | 1.4 × 1.15 × 2.26 | 1.45×1.15× 2.35 | 1.6 × 1.25× 2.48 | ||||||

Q1:Are you a trading company or a manufactory?

A1 :We are a manufactory,can give u best service and low price.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

A2 :We offer you high quality machines with 1 year warranty .

Q3:When can I get my machine after I paid?

A3 :We will deliver the machines on time as the date we agreed both side.