- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11KW

-

Weight:

-

900

-

Dimension(L*W*H):

-

1200*950*1400mm

-

Name:

-

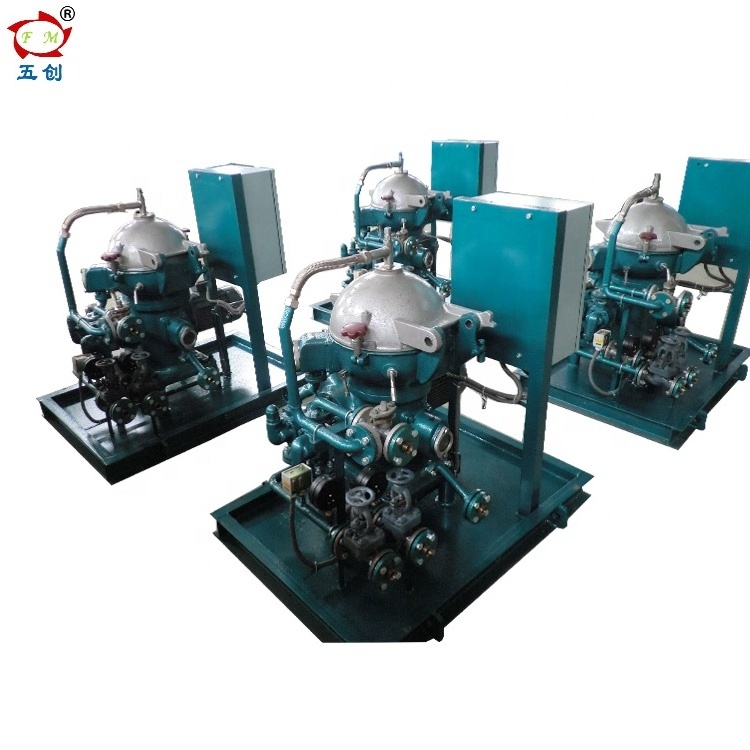

Waste Oil to Clean Oil Disc Stack Centrifuge Separator

-

Drum Speed:

-

6900r/min

-

Capacity:

-

3000L/H

-

Discharge:

-

automatic discharging

-

Motor Power:

-

11KW

-

Separation factor:

-

10000

-

Noise level:

-

≤85 dB(A)

-

Function:

-

solid liquid clarification or concentration

-

application:

-

solid and liquid solid separation

-

MOC:

-

SS304/SS316

Quick Details

-

Place of Origin:

-

Nanjing,China

-

Brand Name:

-

Fivemen

-

Voltage:

-

220v/380v/415v

-

Power:

-

11KW

-

Weight:

-

900

-

Dimension(L*W*H):

-

1200*950*1400mm

-

Name:

-

Waste Oil to Clean Oil Disc Stack Centrifuge Separator

-

Drum Speed:

-

6900r/min

-

Capacity:

-

3000L/H

-

Discharge:

-

automatic discharging

-

Motor Power:

-

11KW

-

Separation factor:

-

10000

-

Noise level:

-

≤85 dB(A)

-

Function:

-

solid liquid clarification or concentration

-

application:

-

solid and liquid solid separation

-

MOC:

-

SS304/SS316

KYDH series separator is mainly applied in the purification and clarification of the diesel, light fuel oil, heavy fuel oil and other mineral oil, to remove the water, moisture, mechanical impurities and some harmful substances of the oil. This model is automatic slag type, high separation efficiency, no need to disassemble to slag. It can be automatic controlled according to requirement which greatly reduce the labor intensity of the operating. This machine by the accurate calibration balancing, little vibration, can be long-running and operated safety and reliable.

|

No. |

Model |

Capacity (l/h) |

Drum diameter (mm) |

Drum speed |

Motor Power (KW) |

Discharge way |

Separator factor |

Weight(kg) |

Size(mm*mm*mm) |

|

1 |

KYDR203CD-23 |

1500 |

230 |

6930 |

2.2 |

Manual |

6170 |

245 |

850*625*985 |

|

2 |

KYDH204SD-23 |

2000 |

270 |

7200 |

4 |

Automatic |

6950 |

550 |

865*645*1100 |

|

3 |

KYDH206SD-23 |

3000 |

315 |

6500 |

5.5 |

Automatic |

7000 |

650 |

900*600*1150 |

|

4 |

KYDH207SD-23 |

4000 |

385 |

6500 |

7.5 |

Automatic |

7500 |

750 |

1100*1050*1250 |

|

5 |

KYDH209SD-23 |

5000 |

430 |

6000 |

11 |

Automatic |

8050 |

900 |

1200*950*1400 |

|

6 |

KYDH211SD-23 |

10000 |

500 |

5500 |

18.5 |

automatic |

8000 |

1200 |

1250*1000*1550 |

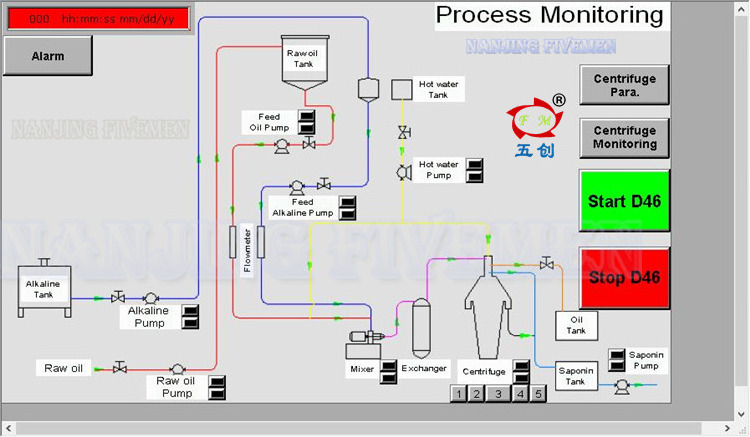

Main function

Main Features

1) Easy in installation and maintation.

2) Full-automatic vibration detector can monitor the vibration strength value of the centripetal pump at any time.

3) Include automatically alarm

4) With PLC control and LED touch screen

5) Heavy -phase centripetal pump adopts European advanced electric positioner control

6) Running in high speed, operating stability,low noise

7) Stability outlet pressure, large regulating sphere and operating easily.

8) Self-discharging , self-cleaning

| Material | Super stainless steel |

| Function | Running in high speed |

| Assembly | Precision assembly |

| Speed | 5000-12000PRM |

Vertical shaft and horizontal shaft

All the parts are made of stainless steel

High quality machining

Refining Machine

1. 12 months guarantee period from machine arrive date.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4.7* 24 hours technical consultation.

5.Your workers could get trained both in our factory and yours.

6.Routine tracing till the machine work properly will be done timely.

7.We will remind you to do the normal maintenance.

8.Your suggestions or any comments & reflection would be treated in priority.

9.Marketing team will visit you during our visit to your country if your require.

Product categories