- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MIKIM

-

Voltage:

-

220V380V/customized

-

Dimension(L*W*H):

-

130*53*105 cm

-

Motor Power (Kw):

-

3-30kw

-

Power (kW):

-

3-30kw

-

Weight (KG):

-

300 KG

-

Warranty of core components:

-

1.5 Year

-

Name:

-

wood pellet machine pelletizer

-

Application:

-

Make Biomass Pellets

-

Pellet size:

-

4-12mm Diameter

-

customer:

-

Canada, Philippines, Indonesia

-

Final product:

-

fuel pellets

-

Spare parts:

-

Flat Die+ Rollers

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Key words:

-

Bio Wood Pellet Machines

-

Ideal moisture:

-

12-15%

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MIKIM

-

Voltage:

-

220V380V/customized

-

Dimension(L*W*H):

-

130*53*105 cm

-

Motor Power (Kw):

-

3-30kw

-

Power (kW):

-

3-30kw

-

Weight (KG):

-

300 KG

-

Warranty of core components:

-

1.5 Year

-

Name:

-

wood pellet machine pelletizer

-

Application:

-

Make Biomass Pellets

-

Pellet size:

-

4-12mm Diameter

-

customer:

-

Canada, Philippines, Indonesia

-

Final product:

-

fuel pellets

-

Spare parts:

-

Flat Die+ Rollers

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Key words:

-

Bio Wood Pellet Machines

-

Ideal moisture:

-

12-15%

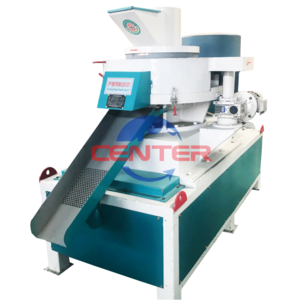

High quality Factory Sale Wooden Cotton Seed Hull wood sawdust rice husk straw grass pellet machine for making wood pelletse

Flat die wood sawdust pellet machine It mainly use biomass from agricultural and forestry processing such as wood chips, straw, rice husk, bark and other biomass as raw materials, and solidify it into high-density pellet fuel through pretreatment and processing. Biomass pellet machines are divided into flat die biomass pellet machines and ring die biomass pellet machines.

We produce biomass pellet making line machines such as wood logs splitter, wood logs debarker, wood chipper, hammer mill, straw bale cutter, grass cutter, mixer, dryer and cooler, pellet machine and briquette machine, pellet packing machine and conveyors etc. , for wood pellet mill details as below :

1.Wood pellet mill can press biomass pellet and fertilizer granules from biomass waste or fertilizer waste, raw materials such as biomass from sawdust, rice husk, agricultural stalk, straw, peanut shell, sun flower, lucerne ,paper ect fertilizer waste such as animal manure, plant waste, chemical products and so on.

2. Wood pellet mill can press 2-8mm diameter pellets, last density is high ,convenient to operate.

there is knive installed nearby pellet mill outlet door, which can adjust last pellet length ,

3. Wood pellet mill has one flat die inside ,its flat die hole can be changed into from 2mm-8mm , for example if install 4mm hole die , then will produce 4mm diameter pellets ,Pellet density is 1.1-1.4ton/m3.

4. Wood pellet mill adopts Germany high technology ,which is our national patent machine. the flat die has the unique advantages to produce larger pressure than ring die pellet mill. in this way rollers and bearings are both enlarged , which can produce larger pressure. for ring die pellet mill, its ring die is restricted by its diameter, rollers can not be enlarged enough, bearing room is smaller , so the bearing are not strong enough to withstand pressure. especially for crude fiber biomass waste, their adhesive is very low and needs high pressure to press good pellets,

5. Wood pellet mill has auto lubricate spare part oil system, which can lubricate three rollers, vertical shaft, bearings, gears automatically , If no auto lubricate oil system, needs to add oil each four working hours manually. Very trouble to operate .

6.wood pellet mill ,contains hydraulic pump , which can adjust pressure between rollers and flat die automatically to fit for different materials pressure ratio, no need to adjust pressure manually each time . Very easy to operate.

Technical Index

|

Model |

Capacity (kg/h) |

Power (kw) |

Specification (mm) |

Weight(t) |

Dimension (mm) |

|

RKL-250 |

100-200 |

15 |

4-6 |

0.5 |

1400*600*1000 |

|

RKL-280 |

150-250 |

22 |

4-6 |

0.65 |

1760*670*1600 |

|

RKL-300 |

100-300 |

30 |

4-8 |

0.76 |

1860*670*1600 |

|

RKL-350 |

300-600 |

37 |

4.5-10 |

2.2 |

1900*850*1750 |

|

RKL-400 |

500-800 |

55 |

4.5-10 |

4.3 |

2300*1100*1900 |

|

RKL-550 |

1000-1500 |

90 |

4.5-12 |

5.5 |

2350*1100*2050 |

|

RKL-800 |

1500-2500 |

160 |

4.5-12 |

6.8 |

3200*1235*2700 |

|

RKL-1200 |

3000-5000 |

320 |

4.5-15 |

19 |

3800*1700*4200 |

Wood pellet machine Features:

(1) Adopt reduction box with low noise, long lifespan gear and can rotate forward and reverse. Other manufacturers adopt low cost bevel gear that cannot rotate reverse.

(2) The pressing die and main shaft adopt Cr12, which is more wear-resisting because of high Cr content. The special heat treatment makes their hardness to be 60HRC. Other manufacturers use 45# instead with low hardness and wear-resistance.

(3) The roller, pressing die, main shaft and roller shaft are processed by vacuum heat treatment other than carburizing and quenching (that other manufacturers use) to have higher hardness, wear-resistance and longer lifespan.

(4) The sealing of spare parts for small pellet machine is excellent. The roller shaft is sealed on both sides, while other manufacturers only seal one side.

(5) The feeding hopper applies whole sheet metal edge instead of welding to be more stable and firm.

(6) The compression ratio of small pellet press determines the quality of your pellets. We have professional team doing the raw material test and have obtained best compression ratio for over 20 kinds of common seen biomass.

(7) The electric components adopt top brands in China to guarantee stable performance.