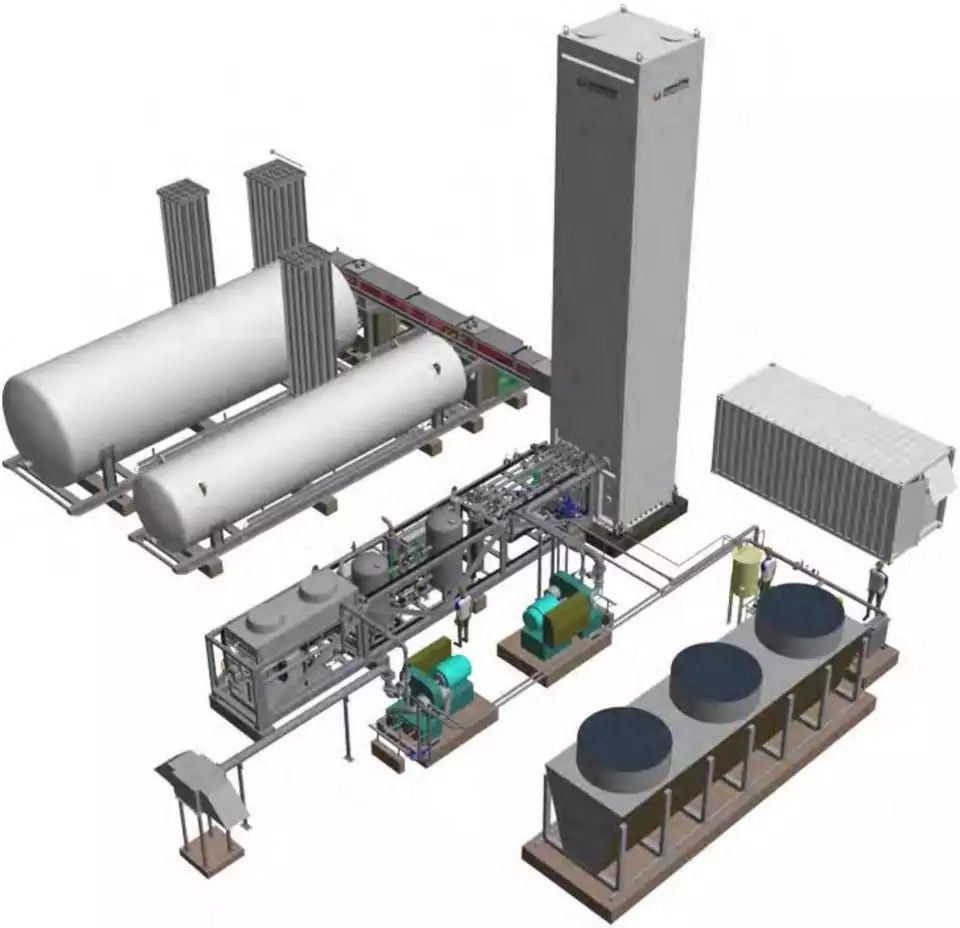

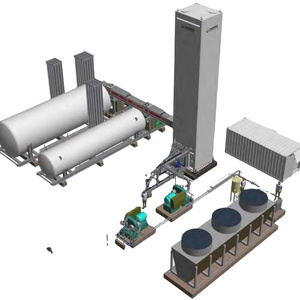

After the mechanical impurities are removed by the filter, the raw air is pressurized by the air compression system and then enters the adsorber. After the air enters the adsorber, the impurities such as water and carbon dioxide in the air are adsorbed by the pre-adsorbent. When clean air enters the oxygen molecular sieve bed, nitrogen in the air is adsorbed. A large number of unadsorbed oxygen and a small amount of inert gas flow from the outlet of the adsorber, namely the product gas. When the ammonia adsorption amount of oxygen molecular sieve reaches saturation. At this point, stop conveying air to the adsorber. After pressure equalization, the airflow flows out from the lower part of the adsorber. With the decrease of bed pressure, the nitrogen adsorbed by oxygen molecular sieve was desorbed, and the desorption gas was extracted by vacuum pump and discharged into the atmosphere.When the adsorber reaches a certain degree of vacuum, the molecular sieve restores the adsorption capacity.

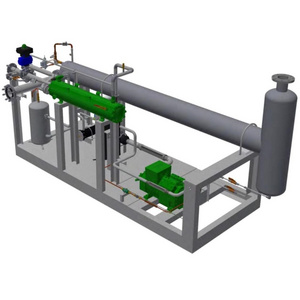

The product gas first enters the oxygen buffer tank , and then enters the oxygen compressor to pressurize. The oxygen buffer tank serves to balance the product gas pressure.

According to the set control sequence, the whole set of oxygen production system starts and stops automatically with one key, and unattended and realize automatic start and stop and remote monitoring. All control and operating parameters are displayed on the industrial computer.