- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380Vcustomized

-

Dimension(L*W*H):

-

1000*700*1000

-

Weight:

-

200

-

Air capacity:

-

3000m3/h

-

Marketing Type:

-

Hot Product 2024

-

Color:

-

Custom Made

-

Post warranty service:

-

Video technical support

-

Provide after-sales service:

-

spare parts

-

authentication:

-

ISO,CE,ASME,,CCC

-

Product name:

-

screw air compressor

-

Cooling method:

-

Air Cooling

-

Tank:

-

custom

-

packaging:

-

wooden case

-

delivery time:

-

3-5 working days

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

sanjianke

-

Model Number:

-

SM-15A, customized

-

Voltage:

-

220/380Vcustomized

-

Dimension(L*W*H):

-

1000*700*1000

-

Weight:

-

200

-

Air capacity:

-

3000m3/h

-

Marketing Type:

-

Hot Product 2024

-

Color:

-

Custom Made

-

Post warranty service:

-

Video technical support

-

Provide after-sales service:

-

spare parts

-

authentication:

-

ISO,CE,ASME,,CCC

-

Product name:

-

screw air compressor

-

Cooling method:

-

Air Cooling

-

Tank:

-

custom

-

packaging:

-

wooden case

-

delivery time:

-

3-5 working days

SM-15A 11 KW

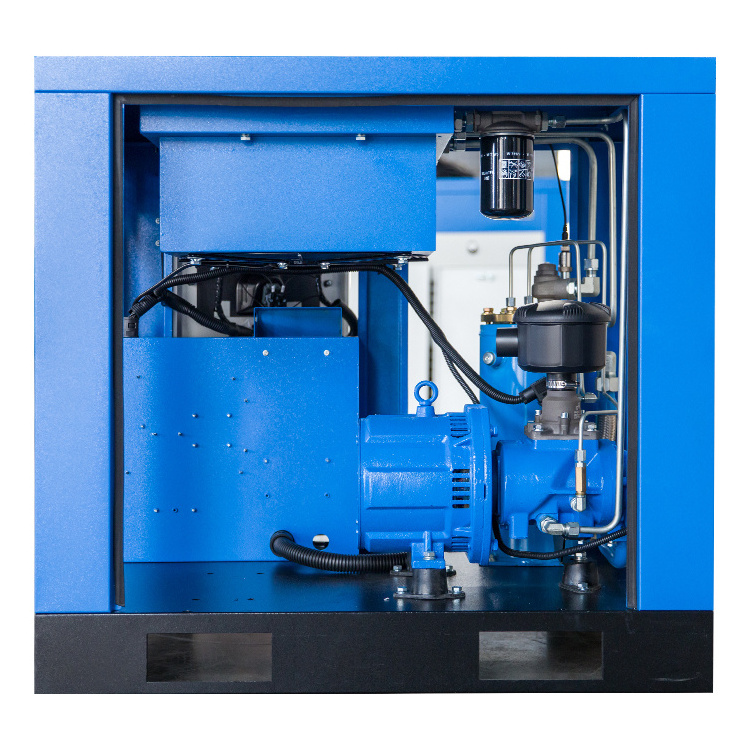

Details of permanent magnet screw air compressor

This is a 15horsepower 0.4~1.1m ³/ min series first stage permanent magnet variable frequency air compressor with a minimum output pressure of 0.6~1.25mpa, power of 11KW, noise of 62 ± 2, and outlet pipe diameter of G3/4. It is a super energy-saving and energy-saving air compressor with a super long lifespan of 15 years

| model | power(KW) |

Flow rate (m ³/ Min) |

Size length * width * height mm | Outlet pipe diameter | weight(KG) |

| SM-15A | 11 | 0.6~1.6 | 1000*700*1000 | G3/4 | 200 |

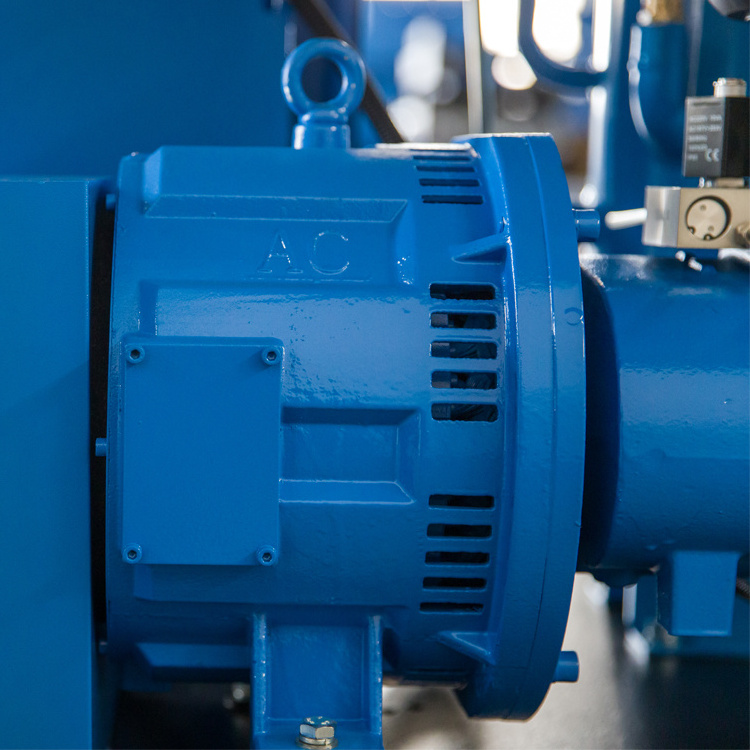

Features of permanent frequency conversion products:

1. Efficient permanent magnet motors, compared to ordinary three-phase asynchronous motors, save about 6-7% energy;

2. Adopting the latest host and integrated shaft structure, compact and stable, with high energy efficiency;

3. Intelligent frequency conversion technology, permanent magnet frequency conversion air compressors can save 20% to 30% energy compared to ordinary industrial frequency air compressors.

Details of 15horsepower 11KW power

connection screw air compressor

Selection steps for air compressors

(for small gas machine manufacturers)

1. Mainly understand the required gas consumption and required working pressure of gas equipment. You can consult with gas equipment manufacturers for specific information, and they will provide you with detailed parameters.

2. After obtaining the gas parameters of the equipment, we can then select the type. Generally, we recommend that the exhaust volume of the air compressor be 1/4 larger than the total gas consumption of the gas equipment, which is beneficial for overload and additional dust blowing in daily work.

3. Power frequency and frequency conversion selection. If the daily working time is more than 20 hours, it is recommended to purchase a permanent magnet frequency conversion air compressor, a permanent magnet with frequency conversion adjustment machine, which is beneficial for energy conservation. If the daily working hours are short and the gas consumption time is short, it is recommended to choose an affordable and durable power frequency air compressor. Both have their own advantages, choose according to your own needs.

4. The selection of air storage tank needs to be at 1/4 of the air compressor's displacement. For example, if the air compressor displacement is 1.2 cubic meters per minute, the air storage tank should be selected at 0.3 cubic meters. This can balance the gas consumption and pumping time, and it will not wait too long to fill the air tank, nor will it be used up suddenly due to the small size of the tank. The pressure of the tank should be equal to or greater than the target pressure of the air compressor. For an 8KG exhaust pressure air compressor, we need to buy an air storage tank with a pressure of 8KG or more. The pressure of the air storage tank cannot be lower than that of the air compressor, and we cannot be tempted by small gains.

5. The post-treatment equipment of the air compressor has a certain amount of gas loss. Both the refrigerated dryer and the adsorption dryer rely on the gas in the pipeline to discharge water, and the automatic drainage valve of the gas storage tank is also affected. The refrigerated dryer loses about 12-17% of the total exhaust volume. If the adsorption dryer is not hot, it usually uses 17% of the air volume to assist in drainage, while the slightly hot one only needs about 7%. If your air compressor system plans to install these post-treatment equipment, you must consider whether the total air volume is enough and whether it needs to be pre installed. Just like the second suggestion, it's best to pre increase it by 1/4.

Sheet metal cutting assembly line

Welding assembly line for chassis

Air compressor testing area

Air compressor assembly area