- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

Dixin

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8000*1500*1550mm

-

Weight:

-

6000 kg

-

Marketing Type:

-

New Product 2022

-

Raw material:

-

PPGI PPGL GI GL

-

Main frame:

-

350mm/400mm H-Beam

-

Roller material:

-

0.05mm Chrome

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Control system:

-

Fully Automatic Computer Control

-

Shaft material:

-

45# Steel Outer Diameter: 75mm

-

Control box language:

-

Add Customer Request Language

-

Thickness:

-

0.3-0.8mm Thickness

-

Material of rollers:

-

CR 12 Quenched HRC 58-62

-

Cutting blade material:

-

Cr 12 High Grade Steel

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

Dixin

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8000*1500*1550mm

-

Weight:

-

6000 kg

-

Marketing Type:

-

New Product 2022

-

Raw material:

-

PPGI PPGL GI GL

-

Main frame:

-

350mm/400mm H-Beam

-

Roller material:

-

0.05mm Chrome

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Control system:

-

Fully Automatic Computer Control

-

Shaft material:

-

45# Steel Outer Diameter: 75mm

-

Control box language:

-

Add Customer Request Language

-

Thickness:

-

0.3-0.8mm Thickness

-

Material of rollers:

-

CR 12 Quenched HRC 58-62

-

Cutting blade material:

-

Cr 12 High Grade Steel

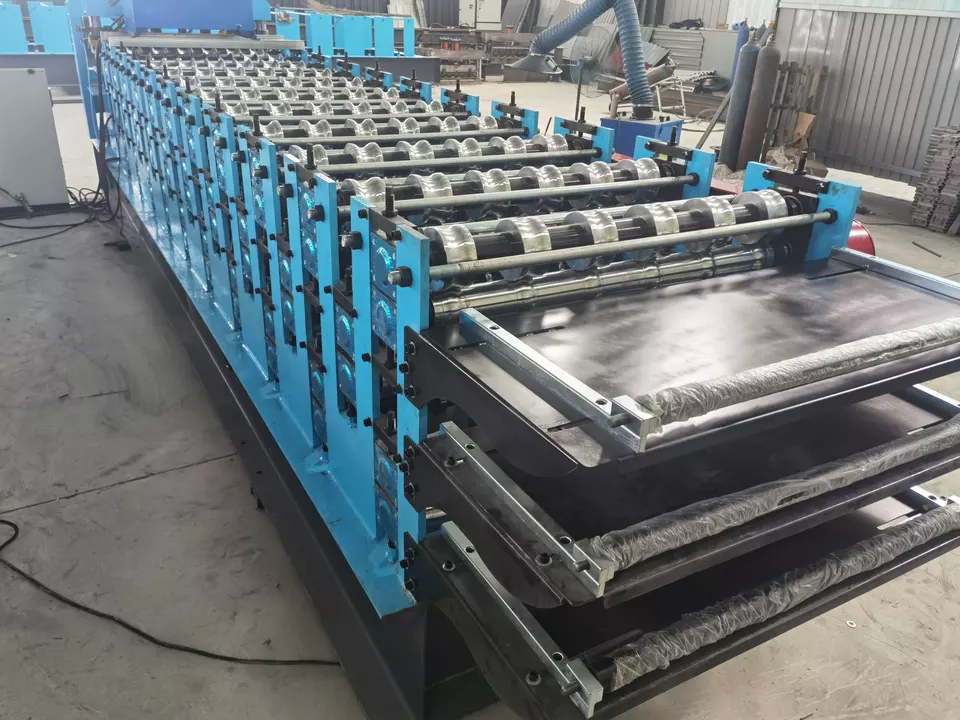

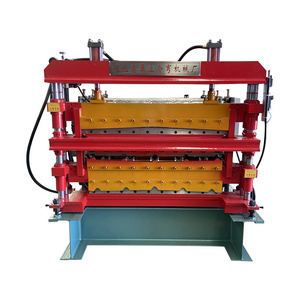

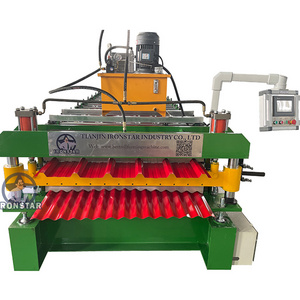

Triple Layer 3 Layer Sheet Metal Roof Profile Roll Forming Machine

The Triple layer tile roofing sheet roll forming machine can produce three different profiles with one machine,including corrugated,trapezoid and glazed tile,customers can customized different profile according to their needs.This type machine has compact structure and takes up less space. It is an ecomomic design.It is suitable for roof tile manufacturers with low investment budget but want to produce several profiles.

Working flow of the production line:

Machine specifications:

| Feeding Part: | ||

| 1 | Positioning plate | adjust the position of both ends to make it fit the width of the feed |

| 2 | Guide frame | play a role in supporting the transport of the material roll |

| 3 | Guide roller | The upper and lower round rollers are designed to make the feeding process more smooth |

|

Roller assembly: |

||

|

1 |

Main roller diameter |

adjust the position of both ends to make it fit the width of the feed |

|

2 |

Roller material |

play a role in supporting the transport of the material roll |

|

3 |

Frame tie rod |

The upper and lower round rollers are designed to make the feeding process more smooth |

|

4 |

Roll forming |

Roll forming process of coil |

|

Cutting after forming: |

||

|

1 |

Guide mechanism |

make the knife holder cut smoothly without deformation of the cut. |

|

2 |

Cast iron tool holder |

obvious shock absorption effect and strong impact resistance |

|

3 |

Blade material |

Cr12 The cutting life exceeds 1 million times |

|

4 |

Rear scissor frame |

Q235 steel plate, annealing treatment after rough turning, finishing |

|

PLC control cabinet : |

||

|

1 |

P L C |

Adopt DELTA high-precision PLC electronic device |

|

2 |

Inverter |

DELTA heavy-duty inverter, running efficiently and stably |

|

3 |

Control components |

DELTA Electronics, with long service life and low failure rate |

|

4 |

Touch screen control |

Input production data and automatically complete production requirements |

Product Features

1. More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.