- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

10400*900*1850MM

-

Power (kW):

-

24

-

Weight (KG):

-

4000 kg

-

Panel Feed Speed(m/min):

-

23m/min, 23m/min

-

Name:

-

Laser Automatic edge banding machine

-

Model:

-

JY-868JKGC

-

Total power of motor:

-

24kw

-

Machine weight:

-

4000kg

-

Dimensions:

-

10400*900*1850MM

-

Thickness of Board:

-

10-60mm

-

Feeding speed:

-

15-23m/min

-

Electrical raising:

-

0.37KW

-

Air pressure:

-

0.6Mpa

-

working thickness:

-

10-60mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JIYU

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

10400*900*1850MM

-

Power (kW):

-

24

-

Weight (KG):

-

4000 kg

-

Panel Feed Speed(m/min):

-

23m/min, 23m/min

-

Name:

-

Laser Automatic edge banding machine

-

Model:

-

JY-868JKGC

-

Total power of motor:

-

24kw

-

Machine weight:

-

4000kg

-

Dimensions:

-

10400*900*1850MM

-

Thickness of Board:

-

10-60mm

-

Feeding speed:

-

15-23m/min

-

Electrical raising:

-

0.37KW

-

Air pressure:

-

0.6Mpa

-

working thickness:

-

10-60mm

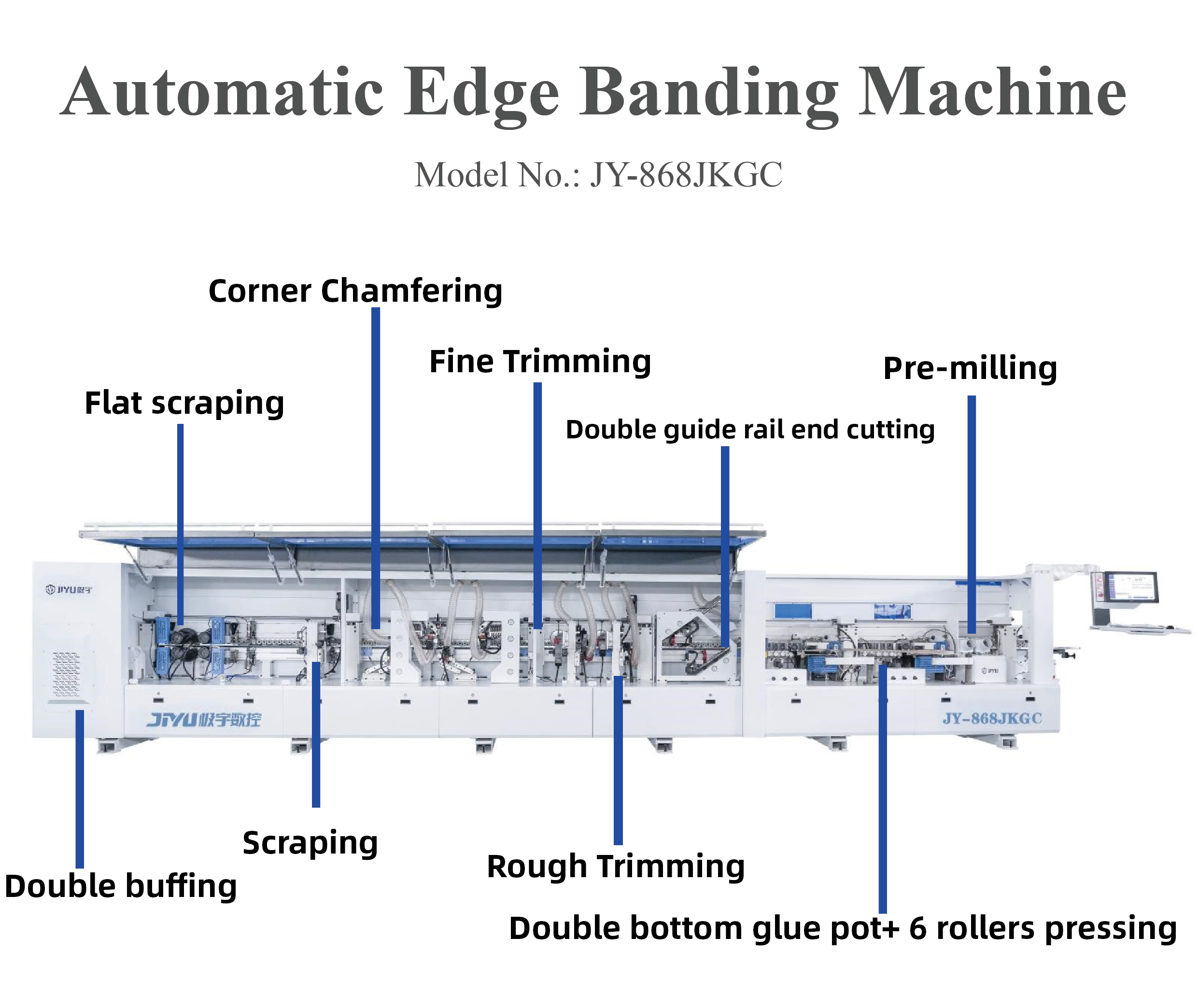

Product Description

Products Details

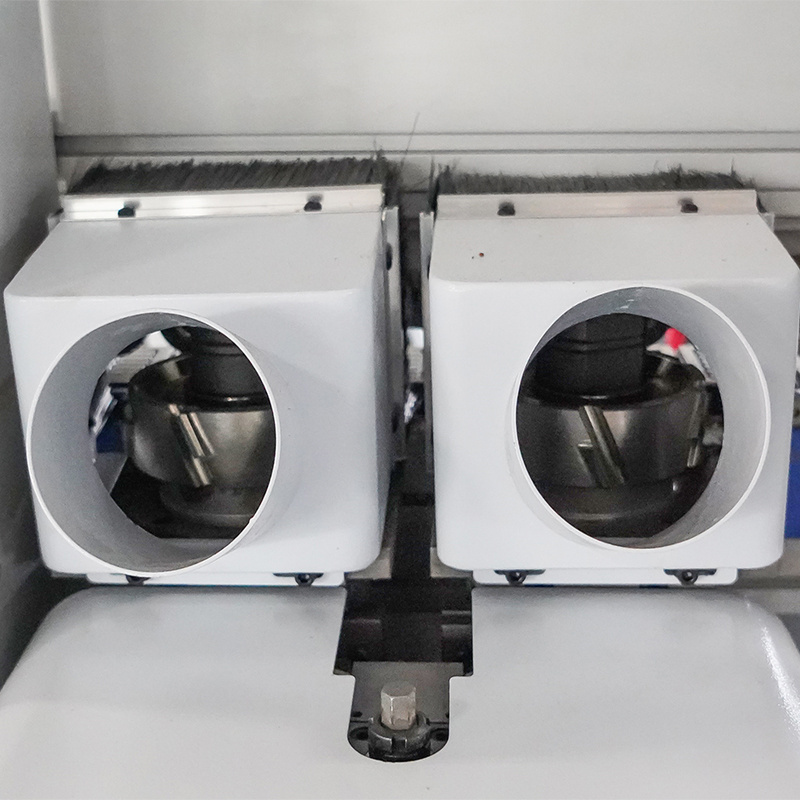

Pre-milling

The diamond pre-milling cutter mills off the corrugated traces and redundant burrs of the spiral trimming knife of

the wood board, so that the board edge fits the edge band more closely, and the bonding is firmer and nicer.

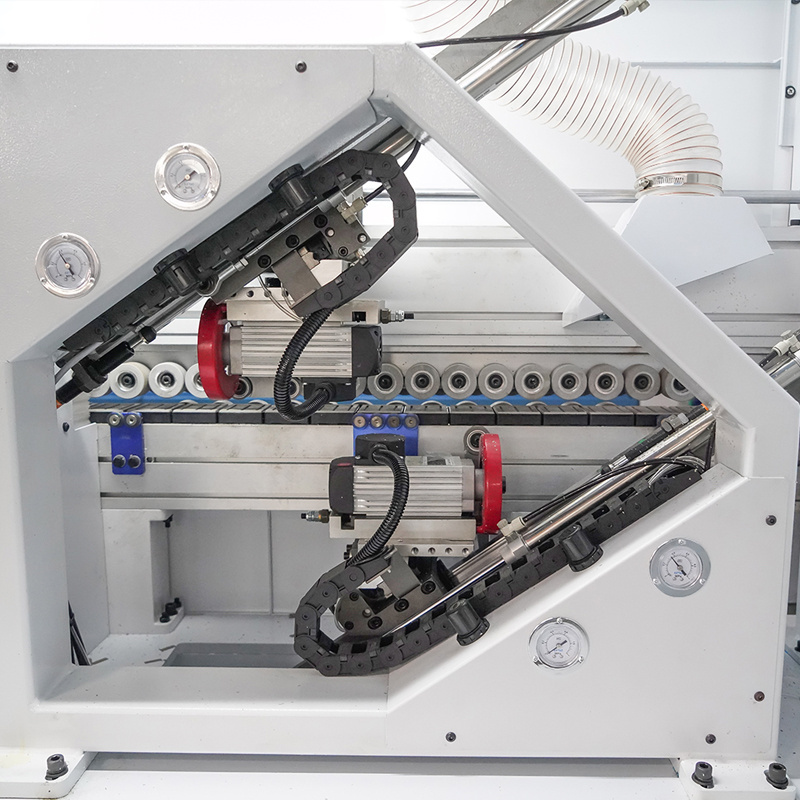

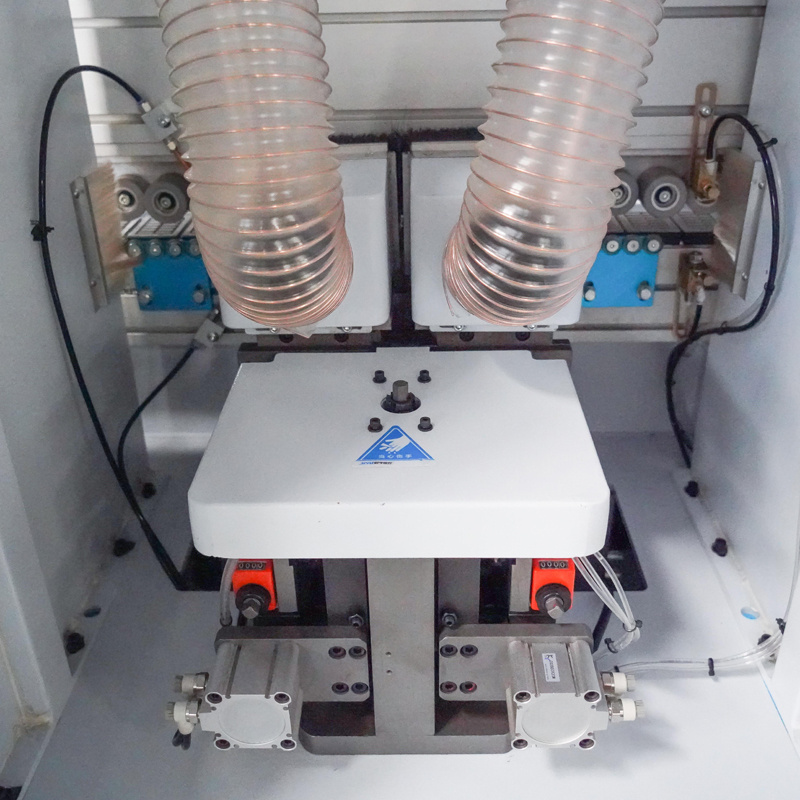

Double bottom glue pot+ 6 rollers pressing

Two sets of bottom glue pots can easily switch between deep and shallow edge banding tape. The glue line is slight and the edge band does not run off. The fit is firm, and the thick and thin veneer can be easily worn.

Double guide rail end cutting

Fast and stable, without bumping the board.

Rough Trimming

The rough trimming knife removes excess edge banding strips to form rounded corners, making the trimming nicer.

Fine Trimming

Fine trimming is to repair the board more carefully on the basis of rough trimming, so as to make the board nicer.

Corner Chamfer

The four corners after the edge banding are trimmed into a small arc, which is more smooth and does not stab hands.

Scraping

The super-hard alloy R knife scrapes the fine lines of the edge strip to make it smooth.

Flat scraping

The alloy flat knife scrapes off the edge banding that is higher than the board surface and the excess residual glue on the board.

Double buffing

The cloth wheel quickly polishes the edge of the edge strip, and the polishing wheel has a larger use area and better polishing effect.

|

Model

|

JY-868JKGC

|

Electric Lift

|

0.37KW

|

|

Machine Size

|

10400*900*1850MM

|

Thickness of Board

|

10-60mm

|

|

Working Pressure

|

0.6Mpa

|

Length of Board

|

≧120mm

|

|

Total Power

|

24KW

|

Width of Board

|

≧60mm

|

|

Feeding Speed

|

15-23m/min

|

Thickness of Band

|

0.4-3mm

|

Related Products

Hot Searches