- Product Details

- {{item.text}}

Quick Details

-

Travel (W-axis) (mm):

-

9000 mm

-

Marketing Type:

-

Hot Product 2021

-

Range of Spindle Speed(r.p.m):

-

100 r.p.m

-

Place of Origin:

-

Shandong,China

-

Brand Name:

-

SUKE

-

Weight (T):

-

6 T

-

Product name:

-

Deep Hole Honing Machine

-

Boring Diameter:

-

30-200mm

-

Product type:

-

Boring machine

-

Feed Rate:

-

5-15m/min

-

Max boring depth:

-

9000mm

-

Motor Power (kw):

-

7.5KW

-

Spindle speed:

-

3-100r/min

-

Controlling Mode:

-

KND or User selection

-

Warranty period:

-

1year

-

Color:

-

red

Quick Details

-

Table Travel (X) (mm):

-

3000 mm

-

Table Travel (Y) (mm):

-

200 mm

-

Table Travel (Z) (mm):

-

200 mm

-

Travel (W-axis) (mm):

-

9000 mm

-

Marketing Type:

-

Hot Product 2021

-

Range of Spindle Speed(r.p.m):

-

100 r.p.m

-

Place of Origin:

-

Shandong,China

-

Brand Name:

-

SUKE

-

Weight (T):

-

6 T

-

Product name:

-

Deep Hole Honing Machine

-

Boring Diameter:

-

30-200mm

-

Product type:

-

Boring machine

-

Feed Rate:

-

5-15m/min

-

Max boring depth:

-

9000mm

-

Motor Power (kw):

-

7.5KW

-

Spindle speed:

-

3-100r/min

-

Controlling Mode:

-

KND or User selection

-

Warranty period:

-

1year

-

Color:

-

red

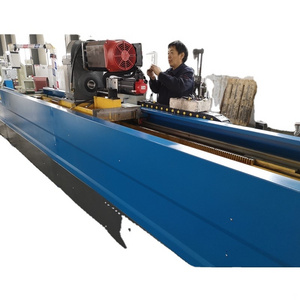

Horizontal Automatic Machine Deep Hole Honing Machine

Product Description:

The CNC honing machine is equipped with PLC numerical control system (optional), square linear guide, AC servo motor. The grinding rod adopts stepless speed regulation,stable commutation, convenient speed regulation, and it is easy to ensure the accuracy of aperture size and reduce labor intensity. During the honing process, the sand bar and the workpiece are always maintained at a constant pressure, so that the sand bar is strongly ground, which ensures the high efficiency of deep hole processing. It is suitable for rough and fine honing of general cylindrical deep hole parts after rough boring. The machine can also perform local honing to correct the taper and ovality of the part. Honed workpieces are made of cast iron and various types of steel, including hardened workpieces. If cold drawn steel pipes are used, direct honing can be performed directly.

This machine tool is specially used for rough and fine honing of the inner wall of cylindrical deep hole parts such as various hydraulic oil cylinders and cylinders, and is especially good at processing stepped cylinders.

Machine Fe a tures

1. High processing accuracy (≤0.03), high finish (≤Ra0.2-0.8)Dimensional accuracy (IT6) is easy and accurate to adjust. The honing head is opened tightly by the top of the oil cylinder.

2. Dimensional accuracy (IT6) is easy and accurate to adjust. The honing head is opened tightly by the top of the oil cylinder.

3. The length of the machine tool is controlled by a numerical control program, and the machining size is controlled by the number of honing reciprocations.

Specifications:

|

|

Project Name |

Parameters |

|

Working range |

Honing diameter range |

Φ 63 —Φ 5 00mm |

|

Workpiece length |

500-1 5 000mm |

|

|

Maximum processing volume |

0.4-1mm |

|

|

Grinding rod box spindle parameters |

C enter height |

100mm-600mm |

|

Spindle Variable speed range |

3-200r/min(Stepless speed regulation) |

|

|

Boring bar torque |

500-3000N.m |

|

|

Feeding parameter |

range of feeding speed |

5-25000mm/min(Stepless) |

|

Pallet move speed |

10m/min |

|

|

Feed torque of boring bar |

≥200N.m |

|

|

Positioning length |

0-1 5 000mm |

|

|

Working precision |

Workpiece honing surface roughness |

≤Ra0.8um |

|

Workpiece polish ing surface roughness |

≤Ra0.4um |

|

|

Workpiece cylindricity |

≤0.02/500mm |

|

|

Workpiece roundness |

≤0.02/100mm |

|

|

|

Mot o r power of boring bar |

15KW AC servo motor |

|

Motor capacity |

Hydraulic pump motor power |

1.5KW |

|

|

Feeding motor |

3.7KW AC servo motor |

|

|

Cooling motor power |

1.1KW two groups |

|

CNC systerms |

KND or customer choose |