- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8.83m*3.18m*5.73m

-

Weight:

-

1-30 Ton

-

Color:

-

Customer's Requirement

-

Warranty:

-

12 months since the date of payment

-

Thermal efficiency:

-

80.4%

-

Feed Water Temperature(℃):

-

104℃

-

Steam Temperature(℃):

-

194℃

-

Application:

-

Industrial Production

-

Rated evaporation:

-

10t/h

-

Item:

-

SZL10-1.25-T-2079 steam output steam boiler

-

Product name:

-

High performance 10t/h steam output stoker steam boiler

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Henan, China

-

Model Number:

-

SZL10-1.25-T-2079

-

Brand Name:

-

SWET(DeSheng)

-

Dimension(L*W*H):

-

8.83m*3.18m*5.73m

-

Weight:

-

1-30 Ton

-

Color:

-

Customer's Requirement

-

Warranty:

-

12 months since the date of payment

-

Thermal efficiency:

-

80.4%

-

Feed Water Temperature(℃):

-

104℃

-

Steam Temperature(℃):

-

194℃

-

Application:

-

Industrial Production

-

Rated evaporation:

-

10t/h

-

Item:

-

SZL10-1.25-T-2079 steam output steam boiler

-

Product name:

-

High performance 10t/h steam output stoker steam boiler

-

Certification:

-

ISO9001

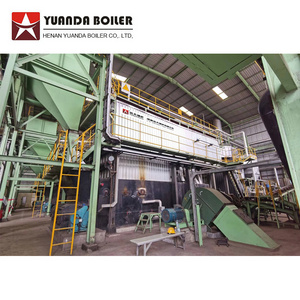

High performance 10t/h steam output stoker steam boiler

SZL series boiler host design as double boiler drum longitudinal layout, set steam water separating device in upper boiler drum, set periodic blow-off device in lower boiler drum, there are water cooling wall tubes at left and right side of furnace.

Use light chain grate add fuel automatically, the back of furnace is re-burning chamber, convection tubes, the tail of furnace is economizer or air preheater, equip with blower, draft fan for mechanical ventilation, and also equip with slag extractor for slagging automatically.

Fuel fall down to chain grate and enter furnace for burning, the flue gas go through furnace, re-burning chamber, convection tubes, economizer or air preheater into tail flue, enter deduster, draft fan and chimney, and finally discharge into atmosphere.

Boiler made materials

Advantages :

Our company provides high quality steel and dedicated to producing the best quality boilers.

The birth of a boiler

Our main products including circular flow bed (CFB)boiler ,gas boiler,coal boiler,biomass boiler,oil boiler,power plant boiler , energy-saving boiler,solider waste boiler, high-efficiency boiler,electric hot water boiler,high-pressure boiler,fully automatic control boiler,wood chip biomass steam boiler,chain grate boiler,condensing boiler ,natural gas steam boiler ,water tube boiler,fire tube boiler,full artificial intelligence boiler ,biomass steam generator,refractory materials,boiler accessories and so on.

Main technical parameters:

| parameter | model | |||||

| SZL6(4.2) | SZL8(5.6) | SZL10(7) | SZL15(10.5) | SZL20(14) | ||

|

Steam

Boiler |

Rated Evaporation Capacity(t/h) | 6 | 8 | 10 | 15 | 20 |

|

Rated Working Pressure(Mpa) |

0.7/1.0/1.25 | 0.7/1.0/1.25 | 0.7/1.0/1.25 | 1.0/1.25/1.6 | 1.0/1.25/1.6 | |

| Steam Temperature(℃) | 170.4/184/194 | 170.4/184/194 | 170.4/184/194 | 184/194/204 | 184/194/204 | |

| Feed Water Temperature(℃) | 20 | 20 | 104 | 104 | 104 | |

|

Body Heating Area (square meter) |

Radiation (squaremeter) |

29 | 27.4 | 32.6 | 40 | 60.4 |

|

Convection (square meter) |

147.2 | 213.2 | 204.1 | 264.1 | 371.5 | |

|

Economizer (square meter) |

87 | 174.4 | 174.4 | 174.4 | 236 | |

|

Air Preheater (square meter) |

/ | / | / | / | 107.8 | |

| Effective Area Of Grate(square meter) | 7.4 | 11.6 | 12.3 | 17.25 | 20.9 | |

| Design Thermal efficiency(%) | 79.2 | 80.4 | 80.4 | 80.4 | 80.4 | |

| Fume Temperature(℃) | 165 | 165 | 165 | 165 | 160 | |

| Fuel | Coal,biomass fired | |||||

operational principle

Our boilers can use both coal and biomass fuel

New Type excellent quality double barrel biomass horizontal steam boiler

Biomass boilers' advantages:

1 . Because the biomass pellet fuel without parathion, does not produce sulfur dioxide and P2O5 combustion, thus it will not lead to acid rain, won't pollute the atmosphere and environment.

2.The biomass pellet fuel is clean, sanitary, convenient for feeding, reducing the labor intensity of workers, greatly improving the labor environment, and enterprises will reduce the cost of labor.

3.After the biomass pellet fuel burns, the ash ballast is very few, greatly reduces the place where piles up the coal ballast, reduces the mucking expense.

Henan Swet Boiler Co., LTD

New Type excellent quality double barrel biomass horizontal steam boiler

Henan Kaifeng Swet (original Desheng) Boiler Co.,Ltd was established in1954,we have continued to provide customers with more than 60 years of quality service,known as the king of China's boiler.It's the national design-ated A-class boilers and D1, D2 class pressure vessel manufacturing key enterprises and has passed ISO9001 international quality management certification system certification.

It holds level 1 boiler installation permit National special equipment manufacturing license . National special equipment installaion remould maintenance permits and so on.In 1979,the world's first circulating fluidized bed boiler was born in our factory.In 2016, in order to meet current emissions and reduce energy consumption re-quirements,our company launched efficient low-emission energy-saving circulating fluidized bed boiler has be-en identified by the national institute of special equipment.

Our advantages

1.Sixty years of boiler manufacturing enterprise culture,top ten enterprises of boiler manufacturing industry in China.

2.The birthplace of China's first circulating fluidized bed boiler, advanced technology and products have been extended so far.

3.More than 2000 environmental protection industrial boilers have been sold at home and abroad, performance, quality and stability.

4.National A-class boiler manufacturing plant,Shanghai Industrial Boiler Research Institute.

5.Teaching and Research Base of North China Institute of Water Resources and Hydropower.

6.Chinese Academy of Sciences circulating fluidized bed R & D base.

Institute of Engineering Thermophysics,Chinese Academy of Sciences.

Highway transport and Shipping

Many domestic and foreign customers visit our factory every year,welcome to our factory.

Our service:

1.Service is part of product, pre-sale and after-sale service are the same important. Customer’s satisfaction is our aim.

2.Consultation Service: Experienced technicians guidance is available on the phone, and on the internet.

3. Warm Service: Based on customers’ request and budget, our experts make efficient, reliable solutions, and we produce strictly following customers’ order. Every customer has the chance to visit our workshops before placing the order.

Some of our domestic customers:

China Petroleum Pipeline Materials and Equipment Corporation.

China Petroleum & Chemical Corporation.

China Aero Engine Group.

COFCO Group Limited.

Weida Paper Co., Ltd.

24 hours at any time welcome customers to inquiry!

QQ:1260552507

Wechat:ChocolateDaisy325

Mobile:+86 15890952986

Twitter: @DaisyZhangZhang

Please send your inquiry at the bottom of this page,click“ send ”now