- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

AX-0002

-

Product Name:

-

Car reflector Shell Injection Mould

-

Mould life:

-

300000-3000000shots

-

Mould material:

-

H13

-

Cavity:

-

4 Cavities

-

Plastic Material:

-

ABS

-

Injection machine:

-

500T

-

Runner:

-

Hot runner

-

MOQ:

-

1

-

Surface treatment:

-

Polishing

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

AoXu

-

Model Number:

-

AX-0002

-

Product Name:

-

Car reflector Shell Injection Mould

-

Mould life:

-

300000-3000000shots

-

Mould material:

-

H13

-

Cavity:

-

4 Cavities

-

Plastic Material:

-

ABS

-

Injection machine:

-

500T

-

Runner:

-

Hot runner

-

MOQ:

-

1

-

Surface treatment:

-

Polishing

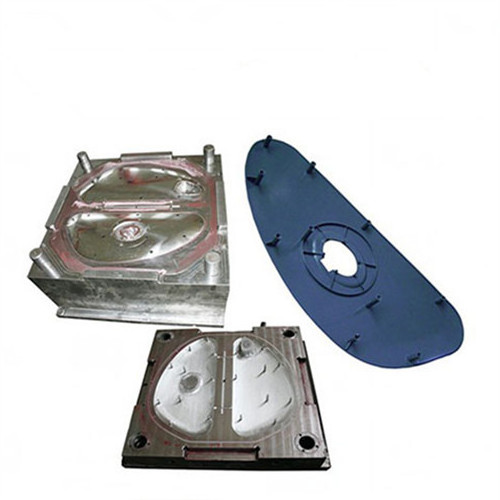

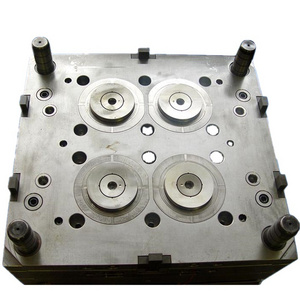

Plastic Car reflector Shell Injection Mould

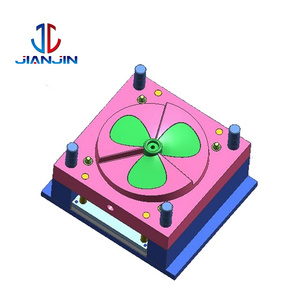

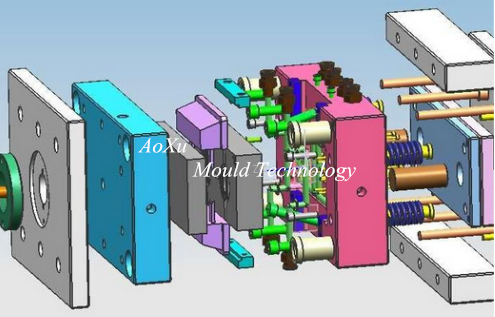

Mold Runner

To avoid the bright spot and weld line on the product surface,this mold we using hot runner (1 piont sprue gate) to cold runner.

Why choose hot runner to cold runner?

-

One hot sprue bushing with many gates into parts.

-

There is not good place to use fully hot runner.

-

Save both the material and the mold cost.Because using hot nozzle cold runner,the main gate without nozzle.

Mold Gate

Side Gate

Side gate is widely used in Two plate mold and multiple cavities which products is small.

Advantages of side gate: simple section shape, convenient processing, fine processing of gate size, small surface roughness value. The gate position can be selected flexibly according to the shape characteristics and filling needs of the plastic parts, such as the frame shaped or ring shaped plastic parts. The gate can be set on the outside or the inside. Because of the small section size, it is easy to remove the gate, small trace, no fusion line, good quality.

Mold Material

Material usually use P20 or H13,we used H13 Material for this mold, It has good polishability and the products will be shiny.

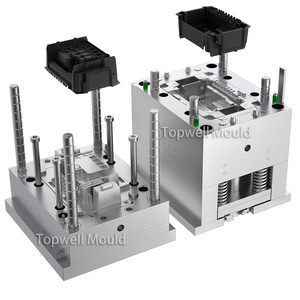

Mold Structure

Lifter+Ejection directly

Mold Cavity

2+2

2 left reflector shell and 2 right reflector shell.

Car Reflector Shell Material

Maily use ABS,TPE,PA,but ABS is the best choose.

Injection Machine

500T

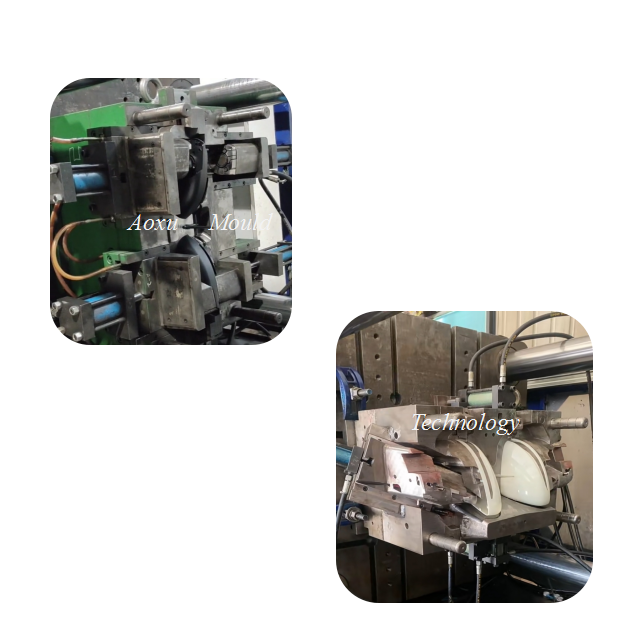

Mold Testing

After we finished the mold, we will inform you that prepare to test the mold for the first time.

Ofcourse we will afford you the testing video and picture. Also some detailed information like temperature,pressure time and so on.

Contact me to get the mold testing video.

We suggest you choose the injection machine 500T.

Our Business scope

- plastic injection mold

- Products Designing & Manufacturing.

- Rapid Prototyping

- Plastic Moulds Designing & Manufacturing.

- Die Casting Mold

- SMC and BMC Mold

- OEM/ODM is welcomed.

Mold Package

Wrapped with Plastic film then fixed on the wooden pallet or wooden case. This according to your requests.

Painting: if you needn't, informed us.

Nameplate:if you no claim, we will use ours.

Mold Maintain

-

Choose suitable injection machine,if machine has high pressure will reduce the mold life.

-

Core and Cavity need paint oil every day.

-

When mold rest,install tightly to avoid dusty into the core.

-

Operating the mold,keep the normal temperature all the time to extend the mold life.

-

Many slides in the mold like guide pin,push rod and core,etc,scrub on time and spray the oil in case of mold stop.

-

Mold operating again,it must clean up the oil,if mold has mirror surface, it must be keep dry after clean.

How to reduce manufacturing mold cost?

First, analyze manufacturability, reasonably determine type and structure of mold, and select materials as needed

Second, shorten mould manufacturing cycle from all links

1. Strive to shorten molding design stage

2. Realize digital manufacturing and information management

3. Advanced technology and details exist at the same time

4. Standardization and standard parts

Third, "specialization, precision, special", social collaboration and corporate culture

- We are direct mould manufacturer,we offer our customers high quality moulds at competitive price and on scheduled production.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: What you make?

A: we specialized in plastic Auto motive mould,Home Appliance mould,stool mould,SMC & BMC mould,Die casting mould,etc.

Q: What is your top skill ?

A: We are the top professional in making Auto motive mould and industry use mould(SMC & BMC).

Q: What is the MOQ?

A: Minimum Order Quantity is one piece/set.If you require more qty,the price will be cheaper.

Q: How many works in engineering department and also in workshop?

A: 4 senior engineers and over 30 technical designers,Total with 100 employees.