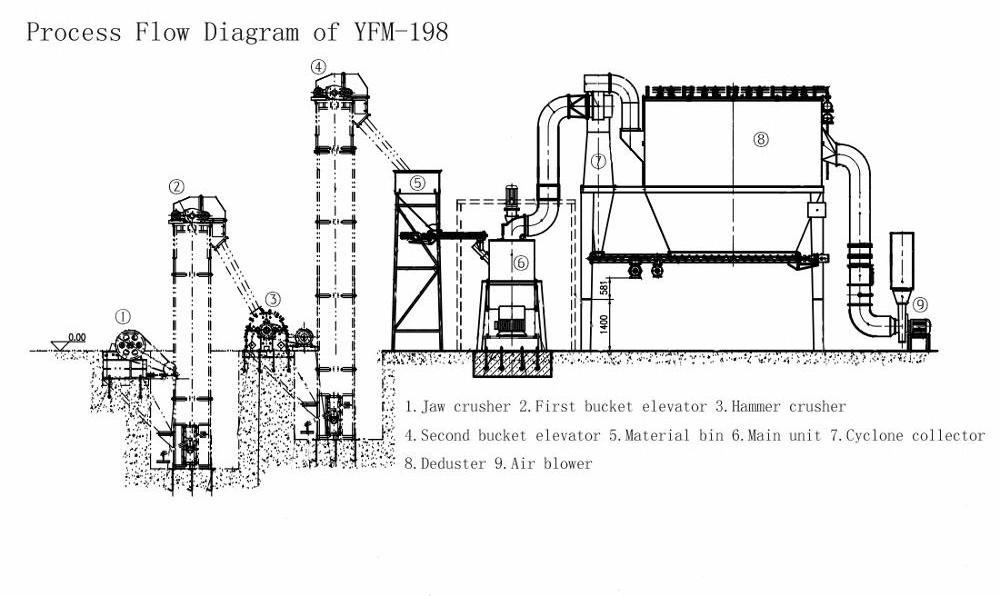

Raw material is fed into grinding chamber via feed port of upper part, then be grinded between rollers and grinding rings into powders. Powders are blowed into upper part. Qualified particle goes into powder collecting system through classifier wheel, others fall and be grinded again.

- Product Details

- {{item.text}}

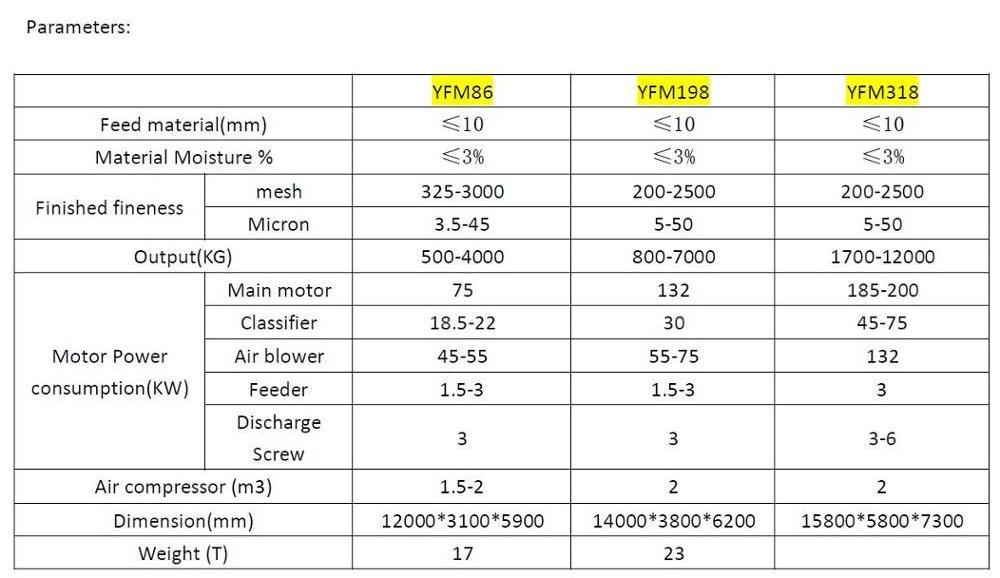

Quick Details

-

Power (kW):

-

245

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Yifeng

-

Voltage:

-

200-600

-

Dimension(L*W*H):

-

14000*3800*6200mm

-

Weight (KG):

-

23000 KG

-

Marketing Type:

-

New Product 2022

-

Grinding ring number:

-

2(3-4 layers)

-

Roller number:

-

20-32 Rollers

-

Finished Fineness:

-

3.5-50um

-

Maximum feed size:

-

10mm

-

CNC or Not:

-

CNC(PLC)

-

Weight:

-

23-60

-

Power(W):

-

300-600

Quick Details

-

Output (kg/h):

-

1 - 8 kg/h

-

Feeding Size (mm):

-

1 - 10 mm

-

Output Size (mesh):

-

300 - 3500 mesh

-

Power (kW):

-

245

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Yifeng

-

Voltage:

-

200-600

-

Dimension(L*W*H):

-

14000*3800*6200mm

-

Weight (KG):

-

23000 KG

-

Marketing Type:

-

New Product 2022

-

Grinding ring number:

-

2(3-4 layers)

-

Roller number:

-

20-32 Rollers

-

Finished Fineness:

-

3.5-50um

-

Maximum feed size:

-

10mm

-

CNC or Not:

-

CNC(PLC)

-

Weight:

-

23-60

-

Power(W):

-

300-600

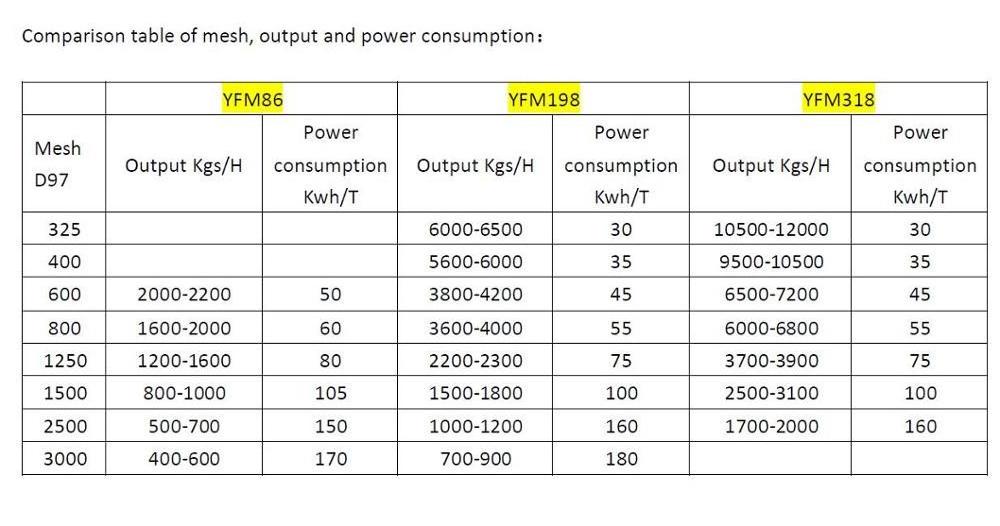

YFM Series Grinding Mill

YFM series Yifeng grinding mill is a new-type grinding mill developed by our company for decades, combining rolling, impacting and grinding to one. It is an ideal ultrafine ground calcium carbonate grinding mill for deeply processing non-metallic minerals which hardness less than Moh's 5, such as

calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite

etc. The finished particle size can reach 325-3000 mesh(3.5-50 microns).

Minerals Usually be Grinded:

Performance and Advantages:

1) Product fineness can reach 325-3000 mesh in one set of machine by adjusting turning speed of the classifier wheel.

2) Compare to ball mill, air-flow mill and stirred mill, YFM mill is lower investment cost, but high output capacity.

3) Low maintenance cost and simple operation.

4) 4-7 days installation, 15-20 days running adoption, reliable, High performance.

5) No dust pollution during operation. Environment friendly sound level outside sound-proof room.

Ground Calcium Carbonate Application.

Calcium carbonate is widely used as an extender in paints and coating, it is also a popular filler in plastics. PVC cables can use calcium carbonate to improve mechanical properties and electrical properties. It also routinely used as a filler in rubbers. Calcium carbonate is added to a wide range of adhesives, sealants, and decorating fillers.

Part 1: Main unit (Grinding system)

Part 2: Deduster (Powder collecting system)

In reverse-pulse-jet baghouses, individual bags are supported by a metal cage, Dusty air enters from the bottom of the baghouse and flows from outside to inside the bags. Bags are cleaned by a short burst of compressed air injection. The powder falls into a storage hopper below. This collecting system works with the help of digital sequential timer (PLC) attached to the pulse valves.

Part 3: Electric control or PLC system

Adapting domestic top level electric components, after 20 years' testing. Our electric control or PLC system is very easy to operate, fully automatic operation, and one button stop, It's also easily adjust. Buyer only needs to adjust current and frequency with visible digitals to reach different particle size from 325-3000 mesh.

Pre-Sales Service

* 7*24 Inquiry and consulting support.

* Sample(Non-metallic Minerals) testing support.

* Pick up from Xiamen International airport, View our Factory and customer site.

After-Sales Service

* 12 months warranty after assembling.

* Free assembling, training, PLC adjustment.

* Lifetime engineers available to service machinery overseas.

|

Grinding mill production line

|

|

|

|

YFM86

|

1*40 HQ

|

|

|

YFM198

|

1*40 HQ + 1* 20GP

|

|

|

Packaging Details

|

All metallic parts will be loaded into container naked, and all spare parts/tools/Electric control cabinet/PLC Cabinet will be packed into Non-fumigation wooden box before loading to keep them clean and integrated.

|

|