capacity:10T,Inner diameter: 500-508mm

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V/440V/220V/415V

-

Dimension(L*W*H):

-

12.5*1.8*2.0m

-

Weight:

-

16500 kg

-

Product name:

-

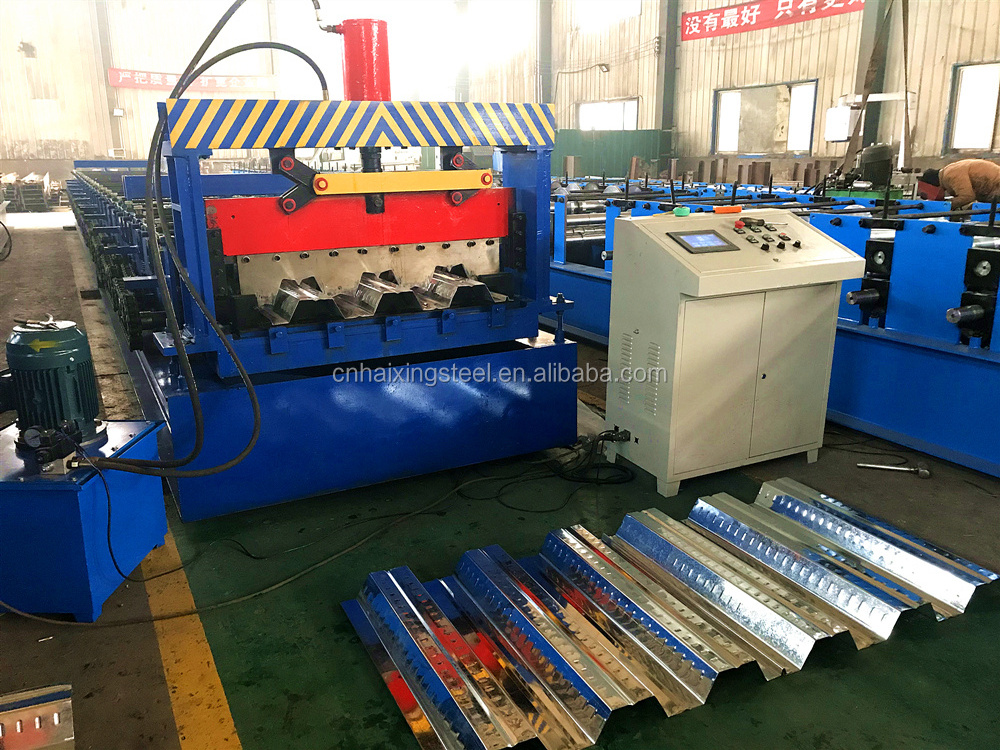

formadora piso cubierta scaffolding metal deck rolling machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

45# Steel Outer Diameter: 90mm

-

Main frame:

-

450 H beams

-

Control system:

-

PLC(imported Brand)

-

Suitable material:

-

galvanized steel coil

-

Thickness:

-

0.5-1.2mm

-

Usage:

-

floor deck sheet

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V/440V/220V/415V

-

Dimension(L*W*H):

-

12.5*1.8*2.0m

-

Weight:

-

16500 kg

-

Product name:

-

formadora piso cubierta scaffolding metal deck rolling machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

45# Steel Outer Diameter: 90mm

-

Main frame:

-

450 H beams

-

Control system:

-

PLC(imported Brand)

-

Suitable material:

-

galvanized steel coil

-

Thickness:

-

0.5-1.2mm

-

Usage:

-

floor deck sheet

Product Description

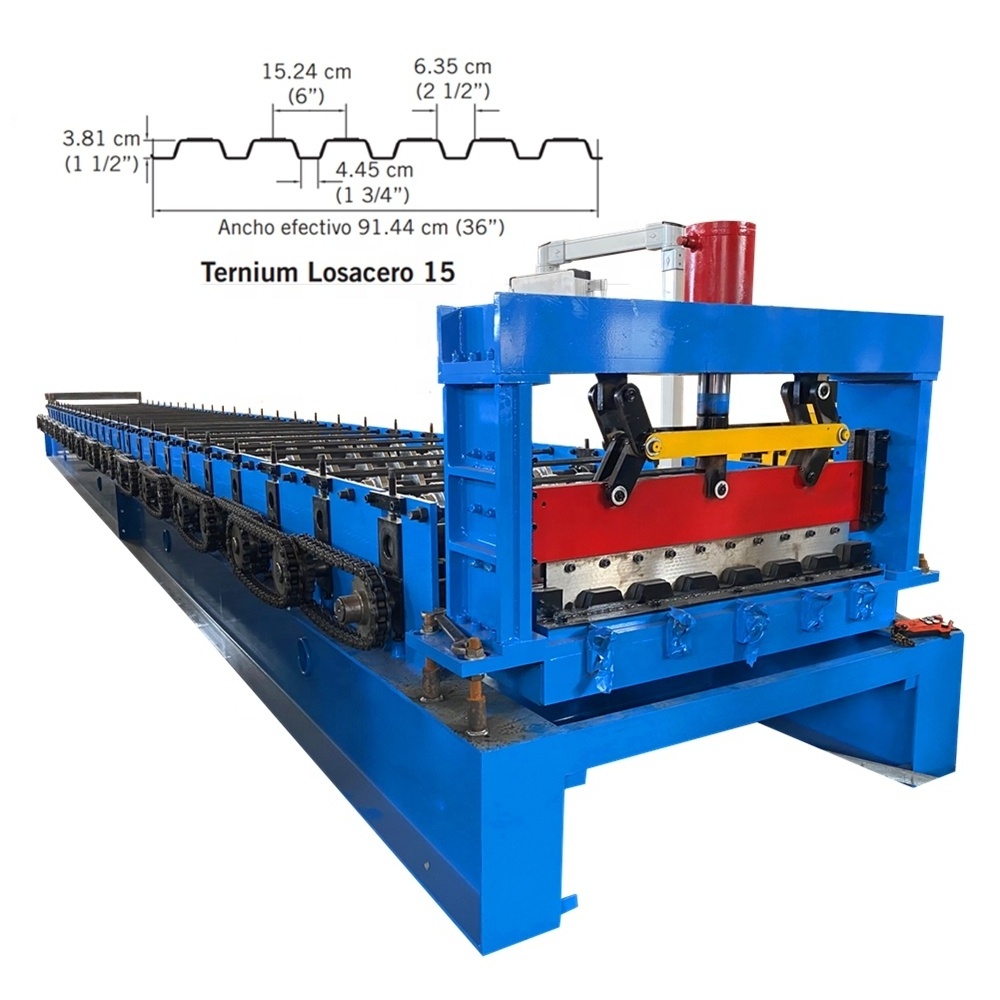

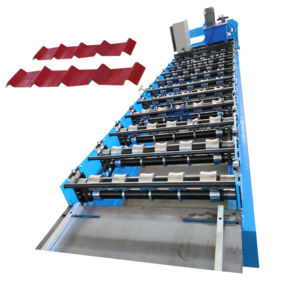

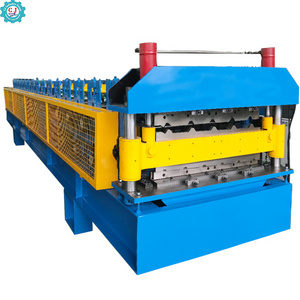

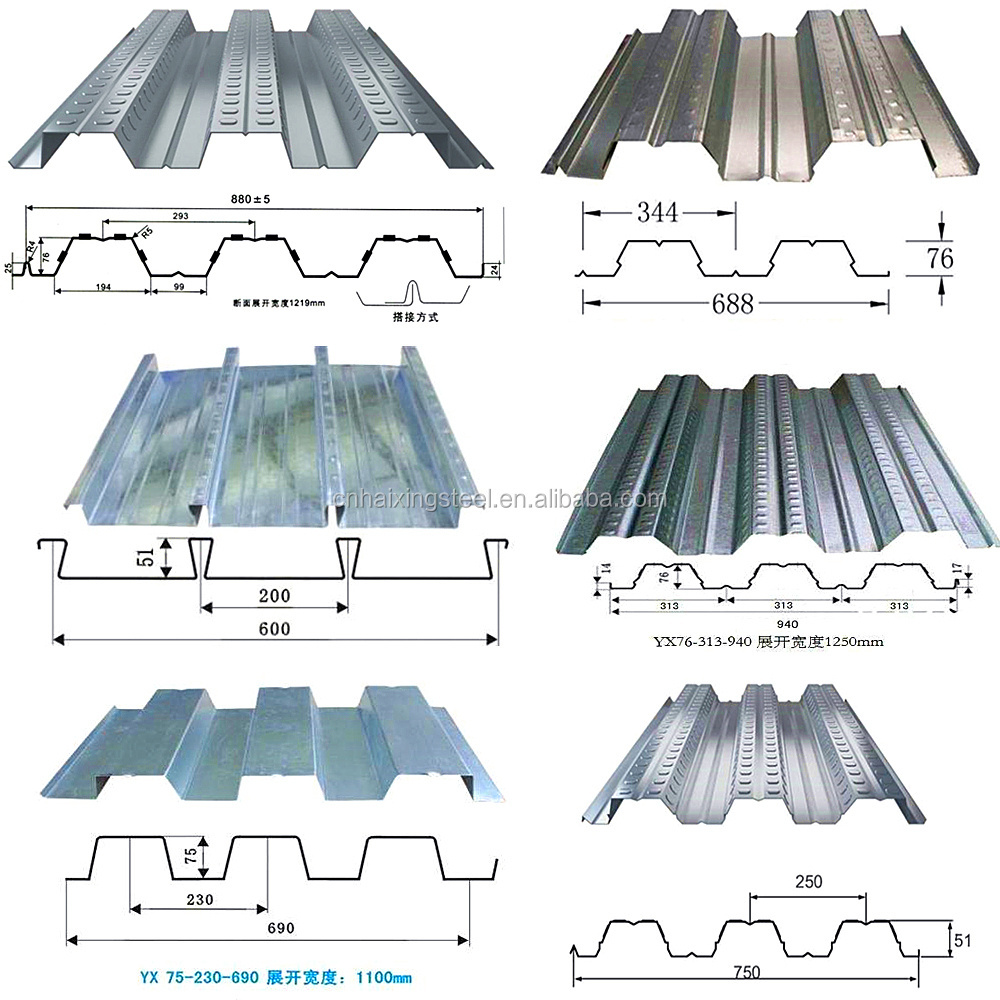

About maquina formadora piso de rollos de cubierta scaffolding metal deck rolling machine :

Our

maquina formadora piso de rollos de cubierta scaffolding metal deck rolling machine

for different models based on different designs or customer's samples . It is a new building material, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center.It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

|

No.

|

maquina formadora piso de rollos de cubierta scaffolding metal deck rolling machine

|

|

|

|

1

|

Suitable to process

|

Alu-zinc steel coil/Galvanized steel coil

|

|

|

2

|

Roller

|

26rollers or according to final design

|

|

|

3

|

Dimensions

|

12.5*1.8*2.0m

|

|

|

4

|

Motor Power

|

15Kw*2

|

|

|

5

|

Pump Station Motor

|

4Kw.Lichao Brand

|

|

|

6

|

Thickness of the plate

|

0.5-1.2mm

|

|

|

7

|

Productivity

|

10-15m/min

|

|

|

8

|

Material of the cutting blade

|

Cr12,Quenched treatment 58℃-60℃

|

|

|

9

|

Diameter of the roller

|

Φ90mm

|

|

|

10

|

Weight

|

About 16500kgs

|

|

|

11

|

Main structure of the machine

|

450 H Beams

|

|

|

12

|

Processing precision

|

Within 1.0mm

|

|

|

13

|

Side panel of machine

|

20 mm

|

|

|

14

|

Chain Wheel and Cycle Chain

|

2 Inch

|

|

|

15

|

Voltage

|

380V 50Hz 3phases or as customer's need

|

|

|

16

|

Control system

|

PLC control (Delta)

|

|

|

17

|

Frequency system

|

Delta

|

|

|

18

|

Drive mode

|

Gear driver

|

|

|

19

|

Touch screen

|

Delta

|

|

|

20

|

Rolling materials

|

45# forging steel with chromium plate

|

|

|

21

|

Length Tolerance

|

±2mm

|

|

Details Images

capacity:10T,Inner diameter: 500-508mm

Name: Motor driver

Main motor size :15Kw *2

Brand: The famous brand from Jermany or according to customer's need

Production Flow

maquina formadora piso de rollos de cubierta scaffolding metal deck rolling machine

working flows as follow :

|

Passive Decoiler

|

1Set

|

|

Feeding Platform with Pre-cutter

|

1Set

|

|

Roll Forming Machine

|

1Set

|

|

PLC Control System

|

1Set

|

|

Hydraulic Cutting System

|

1Set

|

|

Exit Rack for roofing production

|

1 Pieces

|

|

Spare parts

|

One carton box

|

Packing&Shipping

maquina formadora piso de rollos de cubierta scaffolding metal deck rolling machine

export standard packages details

- 2.This producing line is maintained free of charge for 24 months.When the machine is used in China,we will install and debug the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for

exchanged the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the machine,they can teach you how to operater the machines.

After Sales Service

after sales services :

2. Delivery time: Within 25 days after deposit receipt your payment

3. Guarantee period: 24months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your

workers/technician face to face.

FAQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

Company Introduction

Tianjin Haixing Imp & Exp Co., Ltd. Is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of machines. It is located in northwest of Tianjin, China .

As a long history of cold roll forming machine production base. For example :color steel roofing sheet roll forming machines, C&Z Purlin machine, steel roof tile roll forming machines, floor deck forming machines, EPS sandwich panel roll forming machine, highway guardrail forming machine, shearing machine, bending machine, slitting machine.All products comply with international quality standards and are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely. We would like to invite you come and join us to build our mutual benefit.

Visit Our Factory :

1.By airplane to Beijing Airport ,then from Beijing airport to Cangzhou West station or Tianjin station ;

2.By airplane to Tianjin Airport ,we can directly to airport pick up you .

3.If you don't know the way how coming ,you can call Ms Sunny in any time (Mob/whatsApp/Wechat:0086-13512059072)

Roof forming machine raw materials :

In order to help customer save time find good supplier for materials : Prepainted galvanized steel coil ,galvanized steel coil ,galvalume steel coil ( Aluzinc coil) ,aluminium coil and so on ,here we can directly provide customer high quality coil with compatitive price ,good for you reference .

Hot Searches