- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*200*200 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KH

-

Voltage:

-

220v/380v

-

Weight (KG):

-

200 kg

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours

-

Brick size:

-

400*200*200 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KH

-

Voltage:

-

220v/380v

-

Weight (KG):

-

200 kg

Product Description

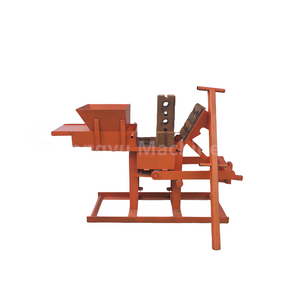

Brick making machine

Manual hollow block making machine is a miniature block machine of high quality, its main characteristic is

saving electricity and saving work force

, and can produce hollow blocks on cement floor without any pallet, especially suitable for small factories.

Features:

1. The body is all made of square steel welding, which is extremely strong and resistant to vibration and stable in operation.

2. The mold box adopts column sliding, compact coordination, synchronous and stable lifting, and the block forming rate is greatly improved.

3. The press head can be slid and displaced, greatly improving efficiency.

4. The lifting part of the mold box is installed to prevent the pressing head from damaging the machine during operation.

5. The four walls of the mold box are equally stressed to ensure high brick density and neat and beautiful edges and corners.

Application and Usage Effects

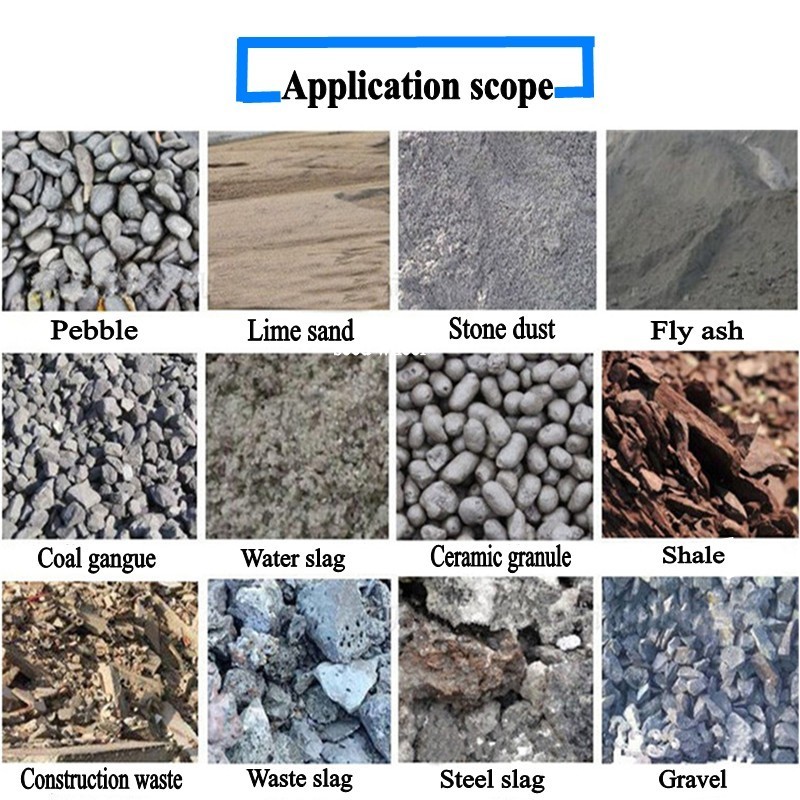

Applicable raw materials:

Employing sand, gravel, and cement, many industrial wastes such as fly ash, slag, steel slag, coal gangue, ceramsite, and perlite can be added in large quantities.

Appliaction:

Widely used in the construction of buildings, roads, squares, waterworks, gardens and other construction.

At present, many markets are still in the state of using hand-made bricks in large quantities for a long time, which not only

takes time and labor, but also has low productivity and low efficiency. This small hand-made brick machine is a new type of machine developed according to the backward market demand. It is characterized by its simple equipment, easy operation and low investment. It is very suitable for the small-scale production and operation mode of family workshop in economically underdeveloped areas.

Specification

|

Model

|

KLZ-1

|

|

|

Power

|

1.1KW

|

|

|

Voltage

|

220V/380V

|

|

|

Weight

|

200KG

|

|

|

Size

|

900x700x1100mm

|

|

|

Operator

|

One person

|

|

|

Molding cycle

|

45s

|

|

|

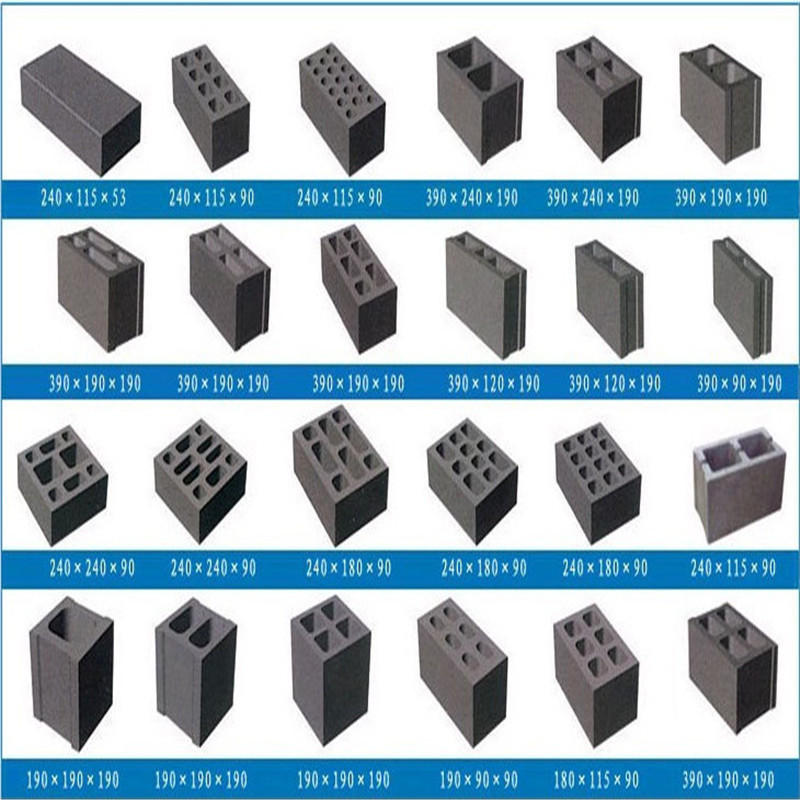

Can be brick type

|

400X200X200(mm) 2 bricks at a time

390X190X190(mm) 2 bricks at a time 390X150X190(mm) 3 bricks at a time 390X120X190(mm) 4 bricks at a time 240X115X53(mm) 12 bricks at a time Different brick types have different output |

|

|

Molds of different shapes of bricks can be customized for you!

|

|

|

Display machine

Product Details

01 Convenient pressure lever

Simple demoulding operation

02 Manual mold push

The upper mold and lower mold can be precisely matched

03 Thickened moving wheels

Four-way fixed wheel is easy to move and not easy to run off

04 Vibration motor

Two 0.55kw motors with small power and strong effect

05 Foot pedal force

Using the principle of leverage, lifting the mold is more energy-saving and convenient

Packing & Delivery

Hot Searches