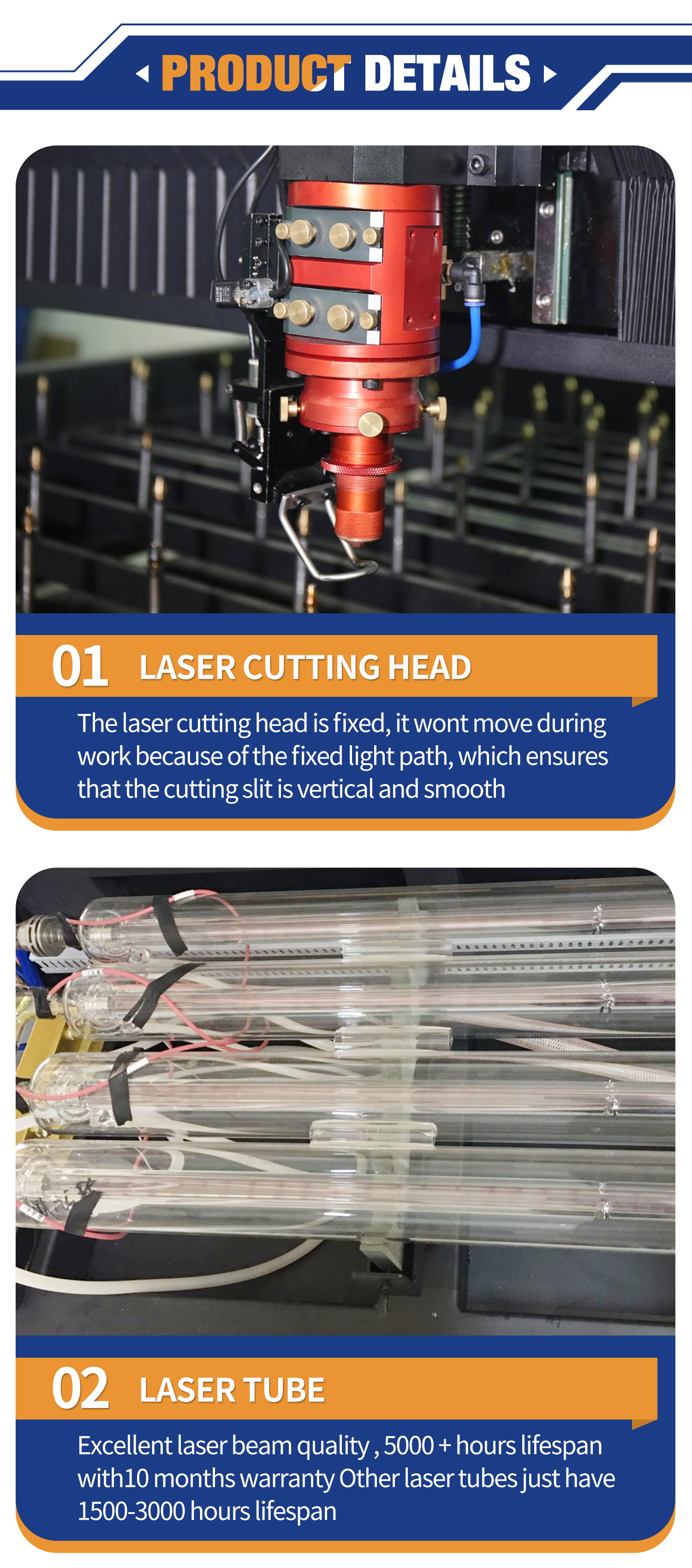

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*2500

-

Cutting Thickness:

-

8-32mm

-

Control Software:

-

ZY-610

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WT

-

Weight (KG):

-

2000 KG

-

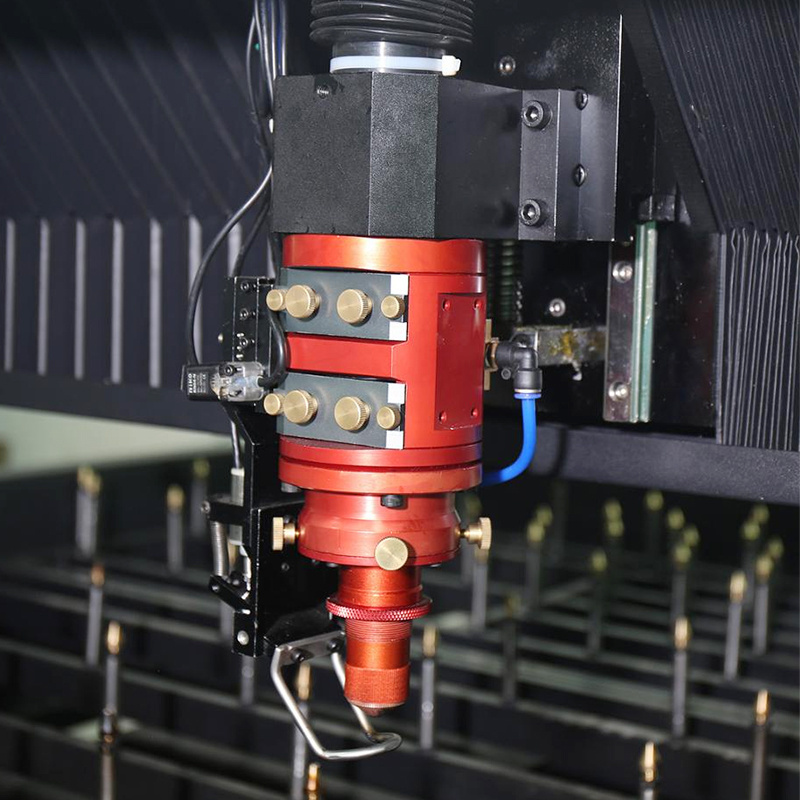

Laser head:

-

Single

-

Cutting materials:

-

Non-metallic Materials

-

Function:

-

Cutting Die Board Making

-

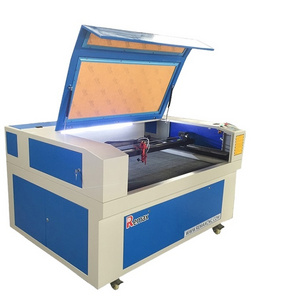

Model:

-

CO2 Laser Machine 1325

-

Driving system:

-

Imported Servo Motor

-

Working table:

-

Blade Table

-

Control system:

-

Cypcut Control System

-

Laser source:

-

Co2 Glass Tube / Laser Generator

-

Power supply:

-

380V 50Hz/ 220V 60Hz

-

Product name:

-

Laser Die Board Cutting machine

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

80meters/hour

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*2500

-

Cutting Thickness:

-

8-32mm

-

Control Software:

-

ZY-610

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WT

-

Weight (KG):

-

2000 KG

-

Laser head:

-

Single

-

Cutting materials:

-

Non-metallic Materials

-

Function:

-

Cutting Die Board Making

-

Model:

-

CO2 Laser Machine 1325

-

Driving system:

-

Imported Servo Motor

-

Working table:

-

Blade Table

-

Control system:

-

Cypcut Control System

-

Laser source:

-

Co2 Glass Tube / Laser Generator

-

Power supply:

-

380V 50Hz/ 220V 60Hz

-

Product name:

-

Laser Die Board Cutting machine

|

WT-LC1500 Specifications

|

|

|

|

|||

|

Laser output power

|

1500Watts axial flow CO2 laser source

|

|

|

|||

|

X-axis travel-length

|

1300mm

|

|

|

|||

|

Y-axis travel-length

|

2500mm

|

|

|

|||

|

Cutting precision

|

±0.05mm

|

|

|

|||

|

Re-Positioning Precision

|

≤0.02mm

|

|

|

|||

|

Cutting width

|

0.45mm, 0.71mm, 1.05/1.07mm at one line (die board)

|

|

|

|||

|

Average. cutting speed

|

60-100meters/hour for 18mm plywood

|

|

|

|||

|

Controlling system

|

PMAC Motion card PMAC

|

|

|

|||

|

Transmission system

|

Ball screw & Linear guide

|

|

|

|||

|

Driving system

|

3 Axial Servo

|

|

|

|||

|

Optical system

|

Semi-optical

|

|

|

|||

|

Moving structure

|

Gantry

|

|

|

|||

|

Chiller system

|

Special Chiller system for laser generator system

|

|

|

|||

|

Machine table whole sizes.

|

3500mm*2500mm*2000mm (1300x2500mm)

|

|

|

|||

|

Laser generator size 1000W

|

L1950 * W850 * H1350MM 600KGS

|

|

|

|||

|

G. Weight

|

2000KGS/2500KGS

|

|

|

|||

|

Voltage (Working table)

|

Single Phrase 220V 50Hz

|

|

|

|||

|

Voltage (Laser generator)

|

3 Phrase 380V/50Hz/30A

|

|

|

|||

|

Pressure of accessory air source

|

0.8Mpa

|

|

|

|||

|

Laser generator gas matched

|

He, N2, CO2(99.99%)

|

|

|

|||

|

H.S. Code

|

8456110090

|

|

|

|||

Related Machine Working Video.

We offer the laser Die Board cutting machine for cutting die board up to 22mm, and Auto Blade bender for 1.3pt 2pt 3pt 4pt and height from 8-65mm .steel rule bender, and die cutting material like steel rule, plywood sheet.

Please check below video to know more of our machines:

1. Auto bender for 2pt and 3pt? https://youtu.be/2pMCjEZUR_8

3. flat die board cutting 1000w? https://youtu.be/RyE7Sb0EoyY

4. flat die board cutting machine 400w/600w? https://youtu.be/ftkd-hQG47s

5.Creasing Rule Cutting Machine? https://youtu.be/e0w4OWajfYQ

1) User manual, CD with video will along with machine for training you how to install, how to use, and how to maintains,

2) Moreover, WhatsApp, Skype, Team viewer online service is available for you.

3) Free training will offer you on our factory, Engineer is available to offer international service!

4) Local agent service available is extending all over the world!

6.How to solve the problem when using the machine?

8. How can I become a Agent of WT Laser?

Agent all over the world is wanted, welcome to visit our factory to know more of each other for start our long term cooperation!.