- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guangmao Machinery

-

Voltage:

-

380V three phrase 50-60hz

-

Dimension(L*W*H):

-

2300*2400*1600mm

-

Weight:

-

900 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Big Jumbo Roll kraft paper

-

Output paper:

-

paper core paper tube

-

Application:

-

Paper Industry

-

Color:

-

Optional Color

-

design:

-

according to clients' needs

-

Machine type:

-

Small Paper Making Machine

-

control system:

-

AC frequency convertor PLC

-

drive way:

-

electric motor section drive

-

Name:

-

cardboard tube making machine

Quick Details

-

Type:

-

cardboard tube making machine and core cutter

-

Production Capacity:

-

Other

-

Max. workable width:

-

1200mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guangmao Machinery

-

Voltage:

-

380V three phrase 50-60hz

-

Dimension(L*W*H):

-

2300*2400*1600mm

-

Weight:

-

900 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Big Jumbo Roll kraft paper

-

Output paper:

-

paper core paper tube

-

Application:

-

Paper Industry

-

Color:

-

Optional Color

-

design:

-

according to clients' needs

-

Machine type:

-

Small Paper Making Machine

-

control system:

-

AC frequency convertor PLC

-

drive way:

-

electric motor section drive

-

Name:

-

cardboard tube making machine

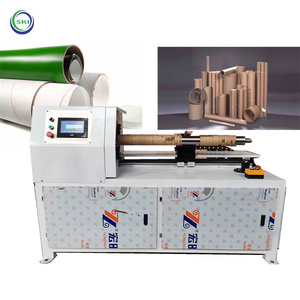

fast supplier good price cardboard tube making machine and core cutter

contact Mr Jorsen Wang for paper making machine!

mobile/whatsup/viber: 0086-13849176576

skype: Jorsenwang

Brief introduction of kraft paper core paper tube making line:

The paper core making line includes kraft paper slitting machine and paper core making machine. It is used to make paper core of certain diameter and thickness from jumbo kraft paper roll.

energy conservation paper core tube making and cutting machine

Ⅰ kraft paper slitting machine

Function

This machine is used to slitting jumbo fluting paper roll into small diameter roll ,the finished small roll can be used to make paper core .it is necessary equipment for making paper core.

Feature:

1.Double disc cutting,upper butterfly disc cutter,concave shape blade;

2.The deckle edge of paper after slitted is smooth and flat,do not have burr;

3.Wrapup firm,both side are flat;

4.Upper blade and below blade can adjusted within the range of 30--1600mm;

5.Easily operation;

High production,it can match up with 3 paper core making machine.

Main technical parameter:

| 1 | base paper width | 1600mm (can be appointed) |

| 2 | diameter of base paper | Ø1200mm |

| 3 | rewinding diameter | Ø650mm |

| 4 | slitting width | >40mm |

| 5 | thickness of base paper | 80-600g/m² |

| 6 | total power | 1.5-4kw |

| 7 | quantity of slitting blade | 18-20 sets |

| 8 | slitting speed | 30-250m/min |

| 9 | winding type | pneumatic swelling |

| 10 | size of upper blade | 2×105×75mm |

| 11 | size of bottom blade | 2×105×75mm |

| 12 | dimension | 2300×2400×1600mm |

| 13 | weight | 900kg |

| 14 | operate worker | 1-3 people |

| 15 | paper loading way | jack |

| 16 | speed control | model of speed regulation |

Ⅱpaper tube making machine

Function:

This machine can make the paper core from fluting paper roll .the paper roll have been cut into with small width .this machine can coat glue on paper and rotate it into paper core.

Feature:

1.Using computer PLC and frequency control system,low noise;

2.Saving power,it can save 50% electricity than ordinary electromagnetic speed adjustment;

3.Locating by infrared ray,automatic cutting;

4.single blade or saw blade are in common use,adjust the cutting length of the paper core arbitrarily;

5.Automatic Gluing,easy operate;

The digital control panel set various operating function,can set arbitrary workings on the machine;

Main Technical parameter

| 1 | operate worker | 1-2 people |

| 2 | paper layer | 3-12 layers (can be adjustable) |

| 3 | the thickness of paper core | 1-8mm (can be adjustable) |

| 4 | the diameter of paper core | 12-125mm(can be changed) |

| 5 | working speed | 1-20 m/min |

| 6 | length of paper core | 1-3m can be adjustable |

| 7 | speed control | frequency conversion PLC |

| 8 | host power | 5.5kw |

| 9 | auxiliary power | 0.75kw |

| 10 | gluing way | single side gluing+double side gluing |

| 11 | fixed-length way | single infrared ray+positioning baffle |

| 12 | winging head | double head single belt decoration |

| 13 | cutting way | single round blade or saw blade are in common use |

| 14 | head quantity for paper winding | 2 or 4 heads |

| 15 | input power | 380V, three phrase, 50-60hz |

Advantage:

1.High speed;

2.High efficiency;

3.Large capacity;

4.Long working life;

5.One year guarantee.

guangmao small scale kraft core making machine and paper tube cutting machine

Delivery time: 35 days after your first payment.

III. After sales service:

1.We can send engineers to your factory, install and test the machine for you, teach and train your worker how to operate this machine;

2.You should pay for our engineers’ air tickets, accommodation, visa, and other necessary fees;

3.If our engineer stay in your factory within one week, we will pay them salary.

If they stay there more than one week, you should pay them the salary after one week.

4.If you don’t need our engineers. We will offer you a detailed machine operating procedures in English. It will make it easy to operate this machine.

engineers and workers install and test paper machines:

toilet tissue paper machine and production line from zhengzhou Guangmao machinery:

related toilet tissue paper processing machinery of guangmao small scale kraft core making machine and paper tube cutting machine:

details of machinery:

packaging of fast supplier good price cardboard tube making machine and core cutter:

1. fixed all the movable parts with plastic films.

2. polystyrene foam plate wrapped around.

3. wrapped with tighted plastic films several circles.

4. fixed machine on the fumigated plywood pallet with iron wire.

5. wrapped with wooden board around and nailed on.

shipment of energy conservation paper core tube making and cutting machine:

1. shipment can be by sea, by train, by truck;

2. delivery time: within 40 days after first payment or L/C.