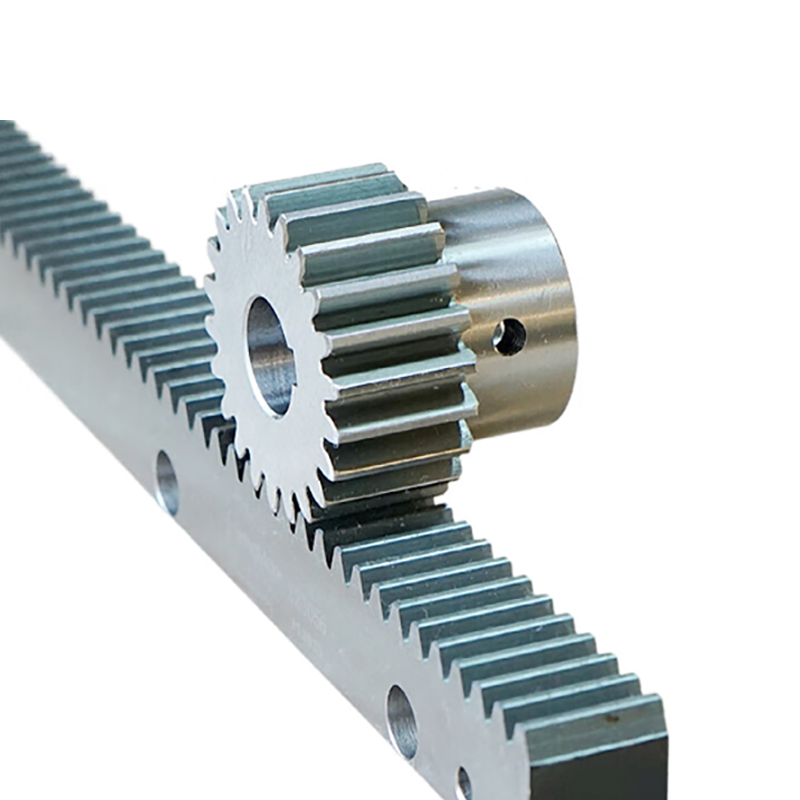

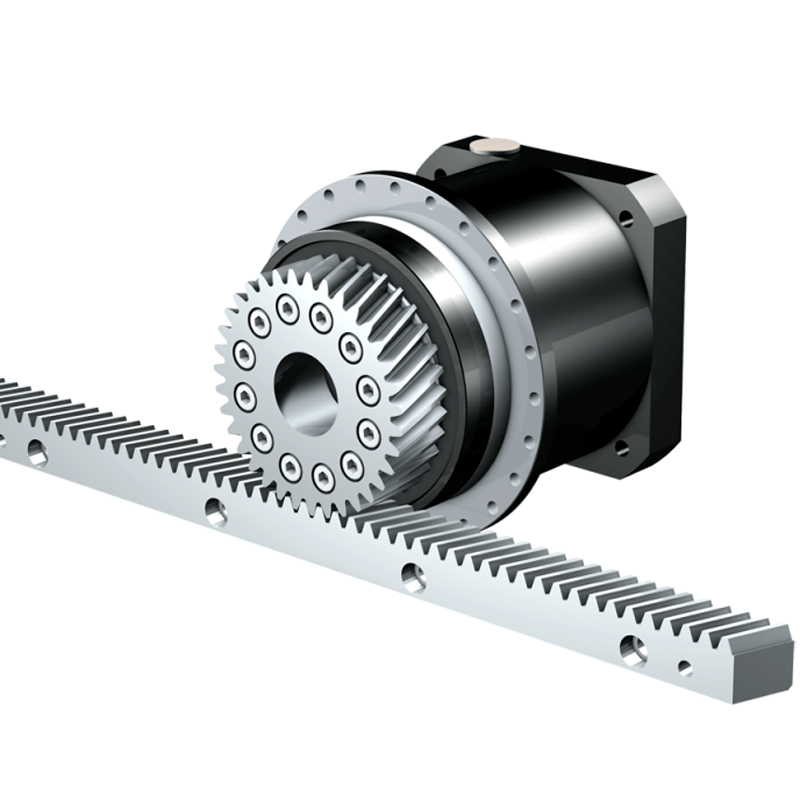

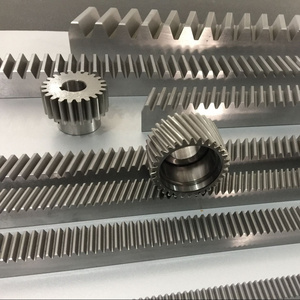

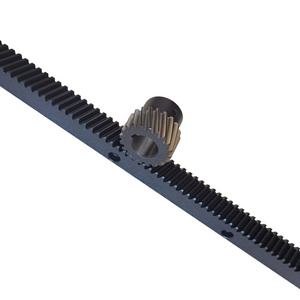

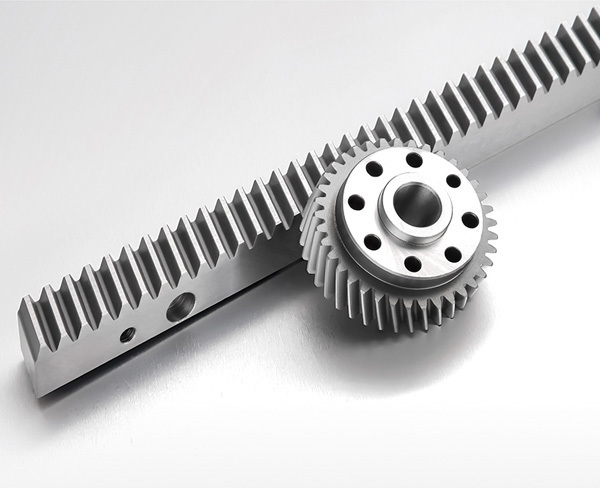

The rack is a transmission component, mainly used to transfer power, and generally matched with the gear into the rack and pinion drive mechanism, the reciprocating linear motion of the rack into the rotary motion of the gear or the rotary motion of the gear into the reciprocating linear motion of the rack. The product is suitable for long distance linear motion, high capacity, high precision, durable, low noise and so on.

The application of rack:

mainly used in various mechanical transmission systems, like Automation Machine, CNC Machine, Building Material

Shops,Manufacturing Plant, Machinery Repair Shops, Construction works and so on.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

M0.5/M1/M1.5/M2/M2.5/M3/M4/M5/M6/M7/M8

-

Brand Name:

-

PYG

-

Product Name:

-

Rack and pinion

-

Model:

-

M0.5/M1/M1.5/M2/M2.5/M3/M4/M5/M6/M7/M8

-

Heat treatment:

-

High frequency, Quenching/Carburization, Teeth hardened

-

Density Precision:

-

C7,C5,C3

-

Color:

-

Sliver

-

Fitting:

-

All type Fittings

Quick Details

-

Applicable Industries:

-

CNC lathe, Laser cutting, Machine tools

-

Weight (KG):

-

4.5

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

M0.5/M1/M1.5/M2/M2.5/M3/M4/M5/M6/M7/M8

-

Brand Name:

-

PYG

-

Product Name:

-

Rack and pinion

-

Model:

-

M0.5/M1/M1.5/M2/M2.5/M3/M4/M5/M6/M7/M8

-

Heat treatment:

-

High frequency, Quenching/Carburization, Teeth hardened

-

Density Precision:

-

C7,C5,C3

-

Color:

-

Sliver

-

Fitting:

-

All type Fittings

Product Overview

High precision rack and pinion

* PYG manufacturing Base is equipped with leading domestic NC machining equipment

* Fully modern equipment and management system

* Strict control of production and manufacturing links

* Leading international technical standards

* Fine process manufacturing to ensure that products have the world's leading level

* Fully modern equipment and management system

* Strict control of production and manufacturing links

* Leading international technical standards

* Fine process manufacturing to ensure that products have the world's leading level

FEATURES AT A GLANCE

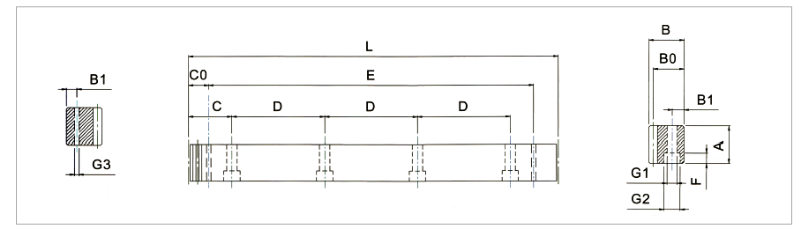

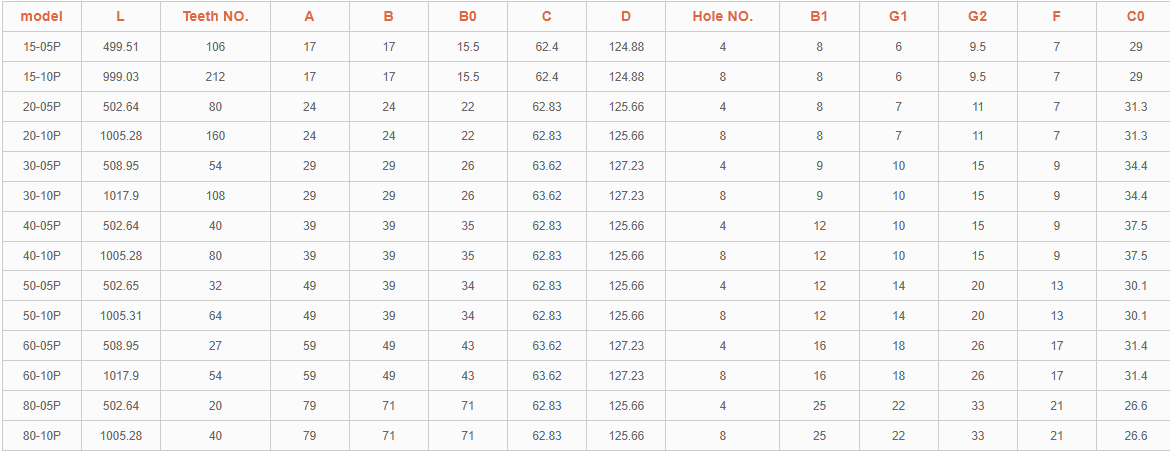

Product Paramenters

Straight Teeth System

① Precision grade: DIN6h25

② Tooth hardness: 48-52°

③ Tooth processing: Grinding

④ Material: S45C

⑤ Heat treatment: High frequency

② Tooth hardness: 48-52°

③ Tooth processing: Grinding

④ Material: S45C

⑤ Heat treatment: High frequency

PRODUCT SPECIFICATIONS

|

Specifications of gear rack and pinion

|

Item

|

Data

|

|

Helical gear rack

|

Helical angle

|

19°31’42’

|

|

|

Pressure angle

|

20°

|

|

|

Precision grade

|

DIN6/ DIN7

|

|

|

Hardness treatment

|

Tooth surface high frequency HRC48-52°

|

|

|

Production process

|

four side grinding,tooth surface grinding.

|

|

Straight gear rack

|

Pressure angle

|

20°

|

|

|

Precision grade

|

DIN6/ DIN7

|

|

|

Hardness treatment

|

Tooth surface high frequency HRC48-52°

|

|

|

Production process

|

our side grinding,tooth surface grinding.

|

QUALITY CONTROL

Exhibition & customers

Our Advantages

1. Competitive price

2. High quality products

3. OEM service

4. 24 hours online service

5. Professional technical service

6. Sample available

2. High quality products

3. OEM service

4. 24 hours online service

5. Professional technical service

6. Sample available

Hot Searches