Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYD

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

25000x2000x3000mm

-

Power (kW):

-

37

-

Weight:

-

36000 KG

-

Name:

-

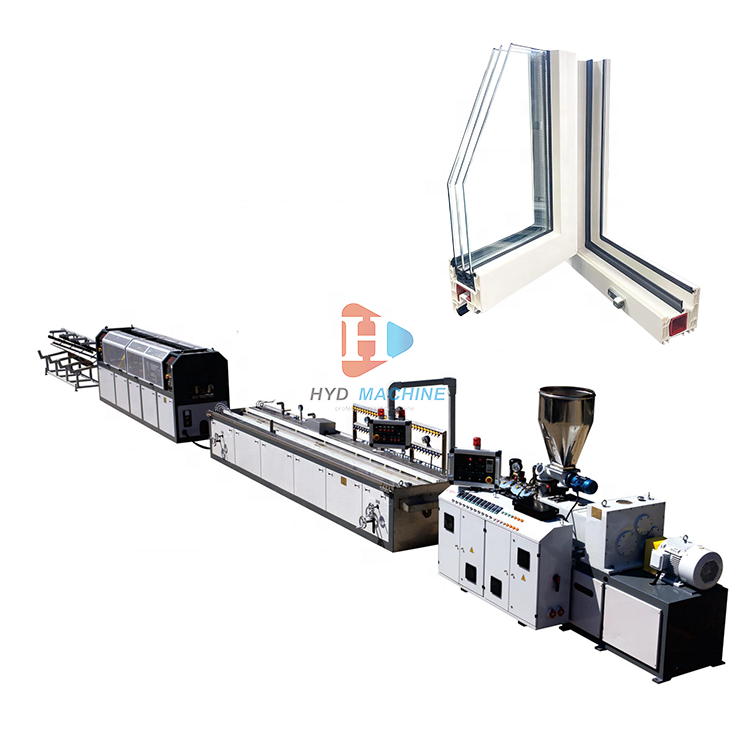

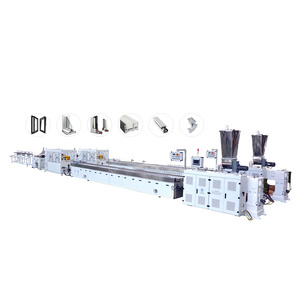

PVC/UPVC plastic window frame sash profile machine

-

Keywords:

-

plastic window profile machine

-

Raw material:

-

PVC Powder+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

SIEMENS Brand

-

Contactor:

-

Schnerder

-

Temperature control:

-

Omron Brand

-

Inverter:

-

ABB Brand

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Other

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYD

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

25000x2000x3000mm

-

Power (kW):

-

37

-

Weight:

-

36000 KG

-

Name:

-

PVC/UPVC plastic window frame sash profile machine

-

Keywords:

-

plastic window profile machine

-

Raw material:

-

PVC Powder+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

SIEMENS Brand

-

Contactor:

-

Schnerder

-

Temperature control:

-

Omron Brand

-

Inverter:

-

ABB Brand

-

After-sales Service Provided:

-

Video Technical Support

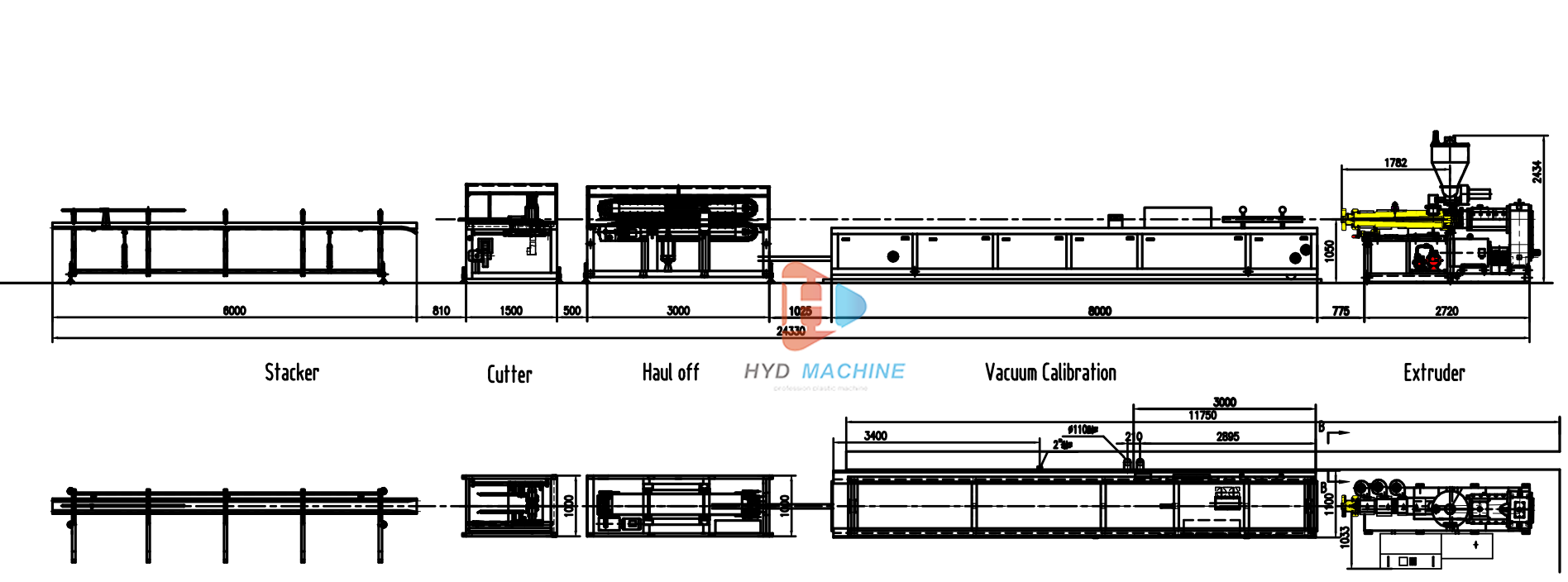

Machine Introduction

>> Use:

This machine is mainly used to produce PVC/UPVC profile sheets, such as plastic door and window profile sheets. The machine adopts PLC control, which is easy to operate, stable in operation, high in production efficiency, long in service life and low in noise.

Machine List

|

Mum

|

Machine

|

Num

|

|

1

|

1st screw loading machine

|

1

|

|

2

|

High speed mixing unit

|

1

|

|

3

|

2nd screw loading machine

|

1

|

|

4

|

Twin screw extruder

|

1

|

|

4

|

Mould

|

1

|

|

5

|

Vacuum calibration table

|

1

|

|

6

|

Caterpillars haul-off machine

|

1

|

|

7

|

Cutting machine

|

1

|

|

8

|

Stacker

|

1

|

Details Images

pvc/upvc plastic profile machine structure

Screw loading machine

Feed the raw material into the extruder and mixing unit

High speed mixing unit

Make the material temperature rises, reaches the material processing before the drying, take off, cooling and so on

Twin screw extruder

The solid material is plasticized and fused into a uniform temperature melt and continuously extruded.

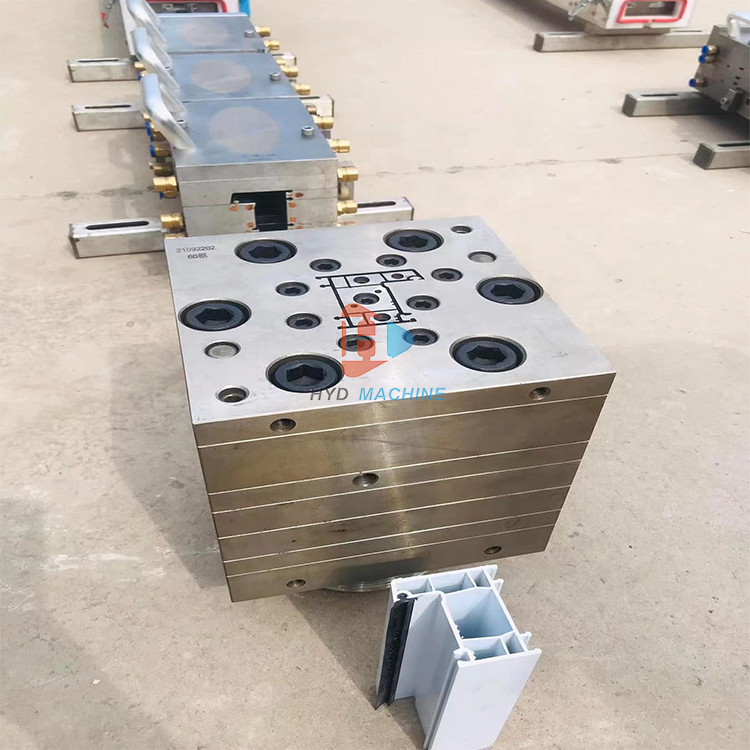

Mould

Including extrusion dies and shaping dies

Vacuum calibration table

After exit from the die head, enter the cooling mold immediately. The mold is vacuized, so that the outer wall of the profile and the surface of the molding mold are tight, and

cooled with water

. The adsorption force of the vacuum is required and uniform, so as to ensure the appearance and dimensional precision and apparent quality of the profile.

Haul-off machine

After the extruder extrudes the raw material through the mold. The tractor clamps the profiles from its outlet and then pulls it to a certain length, which reaches the predetermined extruded length.

Cutter machine

The continuous extrusion products are cut into a certain length by the cutting machine according to the requirements,The cut products fall from the turning rack to the collection box below.

Stacker

plastic profile after cutting neatly arranged

mold pictures

Model reference

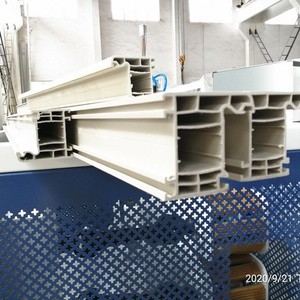

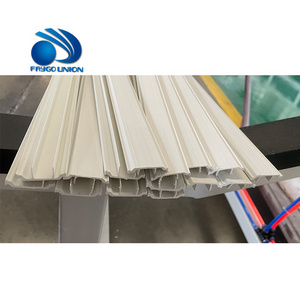

Final Products

Product Paramenters

|

Technical Parameter of twin extruder

|

|

|

|

|

|

|||||

|

Extruder model

|

Power

(kw)

|

Screw size

|

Screw rotation speed(rpm)

|

Designed Output (kg/h)

|

Dimension(L*W*H)

(mm)

|

|||||

|

45/90

|

15

|

Φ45/90

|

34.7

|

70

|

3360*1290*2127

|

|||||

|

51/105

|

18.5

|

Φ51/105

|

|

100

|

3360*1290*2127

|

|||||

|

55/110

|

22

|

Φ55/110

|

|

150

|

3620*1050*2157

|

|||||

|

65/132

|

37

|

Φ65/132

|

|

300

|

3715*1520*2450

|

|||||

|

80/156

|

55

|

Φ80/156

|

|

400

|

4750*1550*2460

|

|||||

|

92/188

|

110

|

Φ92/188

|

|

750

|

6725*1550*2814

|

|||||

Packing&Delivery

Packaging & Shipping:

1.For the loose cargo we will packing by wooden box

3.We can shipping the goods by air or by sea

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's

warehouse to loading

6.We have free spare parts with the machine

.

FAQ

Q:Are you machinery factory or trading company?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A: Yes, we offer testing service on our machine. An additional testing fee will becharged depends on the testing costs(electricity, labor), however, if you eventually made a purchase with us ,the testing fee will counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

A: First we will have a home commissioning in our factory for your inspection. If you need assistance in installing and staff training , we can also send engineers to service overseas and solve all problems.

Q: How to get a quote efficiently?

A: Please kindly click on ' Sent An Inquiry ' Button at the bottom of page,or click "Chat now"on the right side of the page. Leave a message to describe details of your final products ( better with a picture and size drawing), Capacity requirements, We will reply to your inquiry within 12 hours

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Q: How can I make sure the machine running good in my plants?

A: First we will have a home commissioning in our factory for your inspection. If you need assistance in installing and staff training , we can also send engineers to service overseas and solve all problems.

Q: How to get a quote efficiently?

A: Please kindly click on ' Sent An Inquiry ' Button at the bottom of page,or click "Chat now"on the right side of the page. Leave a message to describe details of your final products ( better with a picture and size drawing), Capacity requirements, We will reply to your inquiry within 12 hours

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Zhangjiagang HYD Machine Co., Ltd. is the professional manufacturer for kinds of plastic machines, such as plastic pipe extrusion line, plastic profile extrusion line, small lab extruder

,

waste plastic recycling washing granulation/pelletizing machine, plastic crusher & Shredder and

plastic grinding milling machine /pulverizer

,plastic high speed mixing unit, plastic process auxiliary machines, etc.

The target of Zhangjiagang HYD MachineCo., Ltd is to offer the best quality machines to the customers from all over the world. With the advanced technology, experienced engineers and skilled workers, we have the capability to manufacture specific machines according to customer's requirement. Excellent quality and professional service is the promise made by Zhangjiagang HYD Machinery Co., Ltd to new and old friends.

We are looking forward to establishing the good cooperation relationship with you on the basis of mutual benefits.

We are looking forward to establishing the good cooperation relationship with you on the basis of mutual benefits.

Hot Searches