- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2000 KG

-

Product name:

-

Canning Meat Steam Retort Autoclave

-

Product Keywords:

-

Steam Retort Autoclave

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Material:

-

SUS304

-

Sterilizing way:

-

Hot Steam

-

Advantage:

-

Short Time Sterilization

-

Package:

-

Standard Wooden Case

-

Working condition:

-

Cleaning Area

-

Operation:

-

Automatic Batch Retort

-

Control system:

-

SIEMENS Control System

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DTS

-

Voltage:

-

220V/380V

-

Weight:

-

2000 KG

-

Product name:

-

Canning Meat Steam Retort Autoclave

-

Product Keywords:

-

Steam Retort Autoclave

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Material:

-

SUS304

-

Sterilizing way:

-

Hot Steam

-

Advantage:

-

Short Time Sterilization

-

Package:

-

Standard Wooden Case

-

Working condition:

-

Cleaning Area

-

Operation:

-

Automatic Batch Retort

-

Control system:

-

SIEMENS Control System

Short Description

The Saturated Steam Retort is the oldest method of in-container sterilization used by human. For tin can sterilization, it’s the simplest and most reliable type of retort. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

The Saturated Steam Retort is the oldest method of in-container sterilization used by human. For tin can sterilization, it’s the simplest and most reliable type of retort. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

Product Description

Description

The Saturated Steam Retort is the oldest method of in-container sterilization used by human. For tin can sterilization, it’s the simplest and most reliable type of retort. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

FDA and Chinese regulations have made detailed regulations on the design and operation of steam retort, so although they are not dominant in terms of energy consumption, they are still widely favored by many customers because of their wide application in many old canneries. On the premise of ensuring compliance with FDA and USDA requirements, DTS has made many optimizations in terms of automation and energy saving.

The Saturated Steam Retort is the oldest method of in-container sterilization used by human. For tin can sterilization, it’s the simplest and most reliable type of retort. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

FDA and Chinese regulations have made detailed regulations on the design and operation of steam retort, so although they are not dominant in terms of energy consumption, they are still widely favored by many customers because of their wide application in many old canneries. On the premise of ensuring compliance with FDA and USDA requirements, DTS has made many optimizations in terms of automation and energy saving.

Advantage

1.Uniform heat distribution:

1.Uniform heat distribution:

By removing the air in the retort vessel, the purpose of saturated steam sterilization is achieved. Therefore, in the end of come-up vent phase, the temperature in the vessel reaches a very uniform state.

2.Comply with FDA/USDA certification:

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

3.Simple and reliable:

Compared with other forms of sterilization, there is no other heating medium for the come-up and sterilization phase, so only the steam needs to be controlled to make the batch of products consistent. FDA has explained the design and operation of the steam retort in detail, and many old canneries have been using it, so customers know the working principle of this type of retort, making this type of retort easy for old users to accept.

2.Comply with FDA/USDA certification:

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

3.Simple and reliable:

Compared with other forms of sterilization, there is no other heating medium for the come-up and sterilization phase, so only the steam needs to be controlled to make the batch of products consistent. FDA has explained the design and operation of the steam retort in detail, and many old canneries have been using it, so customers know the working principle of this type of retort, making this type of retort easy for old users to accept.

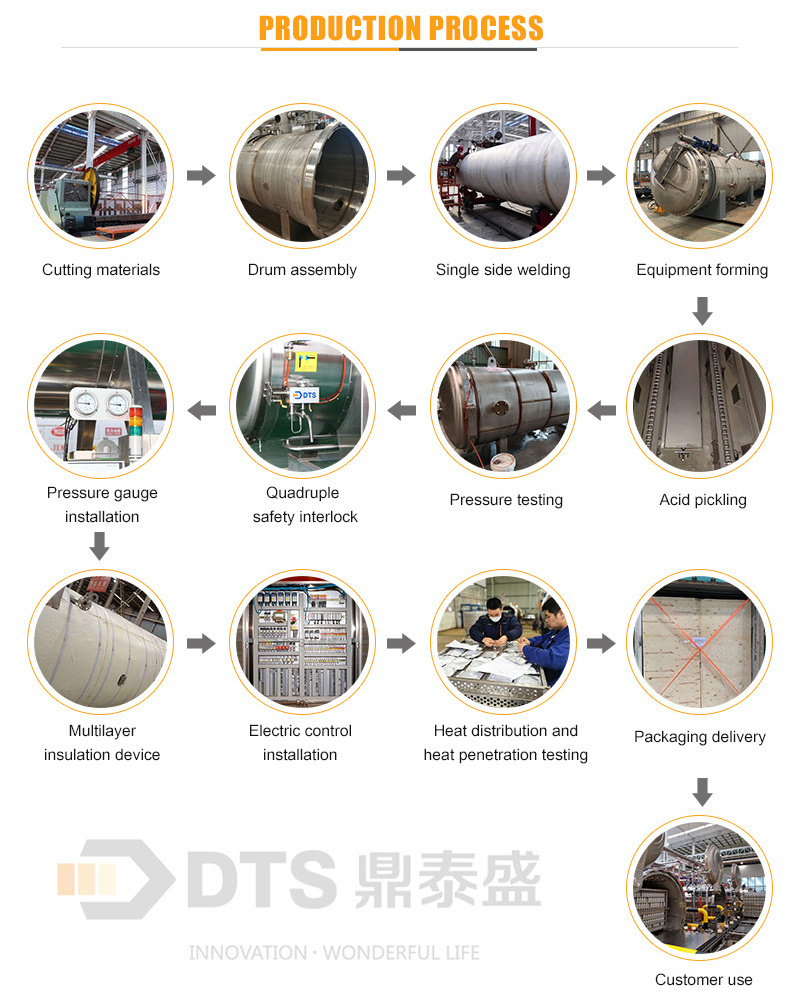

Pruoduction Process

Product Application

Applications

1.Beverages(vegetable protein, tea, coffee): tin can

2.Vegetable and fruit(mushroom, vegetables, beans): tin can

3.Meat, poultry: tin can

4.Fish, seafood: tin can

5.Babyfood: tin can

6.Ready to eat food, porridge: tin can

7.Pet food: tin can

1.Beverages(vegetable protein, tea, coffee): tin can

2.Vegetable and fruit(mushroom, vegetables, beans): tin can

3.Meat, poultry: tin can

4.Fish, seafood: tin can

5.Babyfood: tin can

6.Ready to eat food, porridge: tin can

7.Pet food: tin can

Packing & Delivery

Hot Searches