Easy to set the length of cloth, manner, quantity, speed and

paragraphs

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENGTECH

-

Material Capabilities:

-

Knitted and woven fabric, no-woven, medical gauze

-

Working speed:

-

96m/min max

-

Fabric width:

-

1.6m/1.9m/2.1m/3.0m

-

Diameter of cloth(cm):

-

55

-

Single lay height (mm):

-

180-260(optional)

-

Double lay height (mm):

-

180-230(optional)

-

Fabric bearing weight:

-

75-150kgs(optional)

-

Motors:

-

stepper or Servo

-

Spreading method:

-

single or zig zag

-

Fabric roll:

-

rolling fabric/pieces fabric

Quick Details

-

Applicable Industries:

-

clothing industry

-

Weight (KG):

-

550

-

Marketing Type:

-

China Textile Cutting Auto Spreading Machine

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENGTECH

-

Material Capabilities:

-

Knitted and woven fabric, no-woven, medical gauze

-

Working speed:

-

96m/min max

-

Fabric width:

-

1.6m/1.9m/2.1m/3.0m

-

Diameter of cloth(cm):

-

55

-

Single lay height (mm):

-

180-260(optional)

-

Double lay height (mm):

-

180-230(optional)

-

Fabric bearing weight:

-

75-150kgs(optional)

-

Motors:

-

stepper or Servo

-

Spreading method:

-

single or zig zag

-

Fabric roll:

-

rolling fabric/pieces fabric

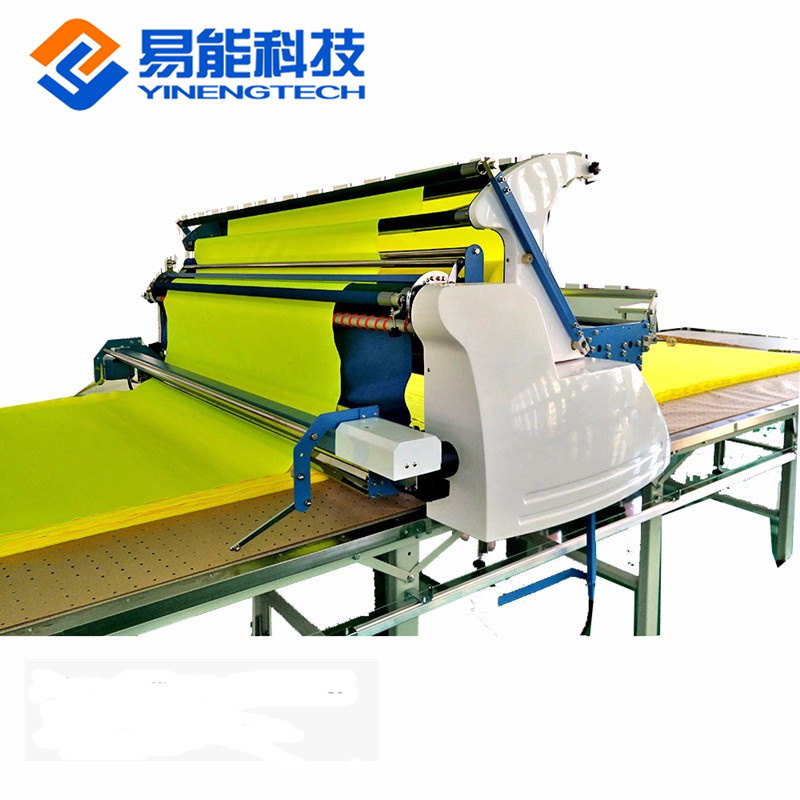

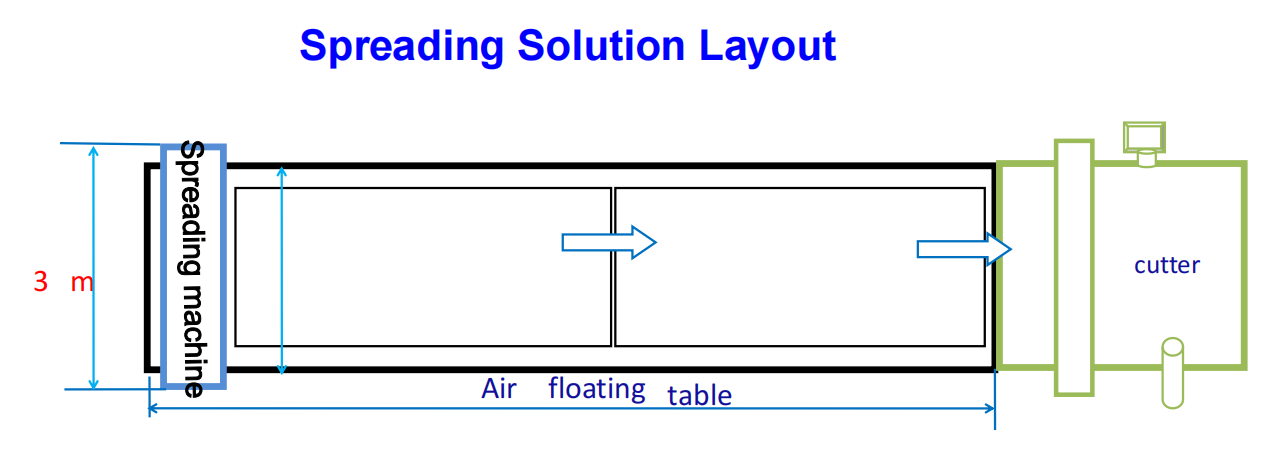

Spreading machine cost effective/Auto fabric spreading machine

Detailed Images

Machine advantages:

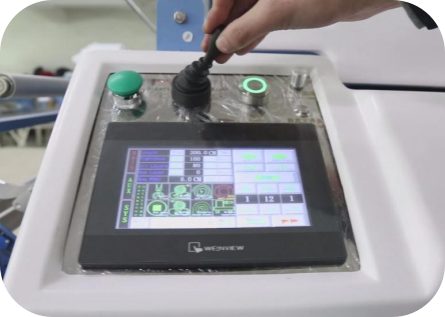

LCD touch control device

The transmission mode adopts high-precision rack and gear transmission system, which has high transmission accuracy, stable start and stop, and long service life.

Folding device:

Can be used for round-trip cloth

Automatic fabric pre -loosening device

The first loose cloth and then auxiliary release, that eliminate the tension of pulling cloth and protect the cloth quality.

Automatic lifting device

According to the thickness of cloth to set the amount of increase,

with the cloth.

with the cloth.

Machine detail

|

Model.NO

|

KP-L160

|

KP-L190

|

KP-L210

|

KP-L300

|

|

Fabric width(mm)

|

1600

|

1900

|

2100

|

3000

|

|

Voltage(v/hz)

|

220V 1ph 50/60

|

2

20V 1ph 50/60

|

220V 1ph 50/60

|

220V 1ph 50/60

|

|

Motor Power(kw)

|

1.5

|

1.5

|

2.2

|

2.5

|

|

Working Speed(m/min)

|

96

|

96

|

100

|

100

|

|

Single Pull Height

|

200

|

200

|

200

|

200

|

|

Double Pull Height

|

180

|

180

|

180

|

180

|

|

Fabric Weight(kg)

|

75

|

75

|

80

|

80

|

|

Diameter of Cloth(mm)

|

600

|

600

|

600

|

600

|

|

Spreading method

|

Single /Zigzag

|

Single /Zigzag

|

Single /Zigzag

|

Single /Zigzag

|

|

Machine Dimensions(mm)

|

2150*1850*850

|

2450*1900*850

|

2750*1900*850

|

3250*1900*850

|

|

Package Size(L*W*H/mm)

|

2716*2000*1215

|

3016*2000*1215

|

3250*2000*1215

|

3930*1640*1240

|

|

Machine weight (kgs )

|

680

|

720

|

750

|

860

|

1. Automatic stop and return back to original position once cloth spreading finished.

2. Machine will auto shutdown once more than 5 minutes no operation/working on it.

3. When any emergency brake happen, the machine won’t drag the cloth.

4. Adopt Taiwan imported PLC touch LCD screen operation system, easy and convenient to operate.

2. Machine will auto shutdown once more than 5 minutes no operation/working on it.

3. When any emergency brake happen, the machine won’t drag the cloth.

4. Adopt Taiwan imported PLC touch LCD screen operation system, easy and convenient to operate.

5. Automatic spreading cloth system, cloth spreading very smoothly and non-tension spreading through roller convey belt. no pull and no size change to cloth.

6. Double and single pull split structure

7. Automatic sharpening function and adjustable knife row distance.

8. Streamline shape, which can reduce wind resistance, reduce noise, reduce vibration.

6. Double and single pull split structure

7. Automatic sharpening function and adjustable knife row distance.

8. Streamline shape, which can reduce wind resistance, reduce noise, reduce vibration.

FAQ

Q: What’s the package?

A: We have 3 layers package: The outside is plywood case, which is fumigation-free packaging. In the middle is covered with thick sponge to protect the machine from shaking. Inside this is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation.

Q: How to install and run the machine?

A: Our engineer have installed and tested the machine before shipping. No parts need installed.

For running machine, we have menus and videos to show you for training. And we also will training you on line. Most of customers training to run the machine like this, very little customer come factory for training.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us ASAP and do not try to fix the machine by yourself or someone else. We will response within 24 hours as quickly as we can to solve it for you.

Company information

Wuhan King Suntime CNC Equipment Co., LTD is established in 2002, we are professional in reaching, manufacturing full set of automatic cutting system, the production include automatic multiply fabric cutting machine & Mono layer cutter &spreading machine. We are striving to provide you the machine based on our several years of practical production experience.

YINENGTECH Market in the world

Hot Searches